Microwave quenching based sludge pyrolysis disposal method

A technology of pyrolysis and sludge, applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of very high automatic control level and large space required, and achieve the elimination of toxic and harmful gases such as dioxin , Strong practicability and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

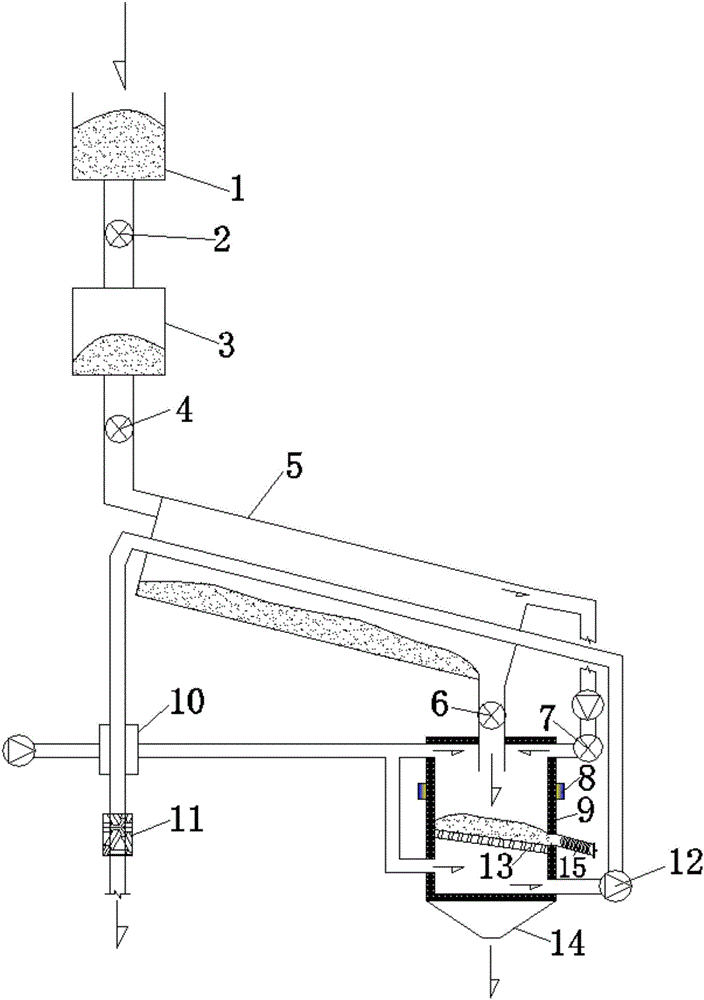

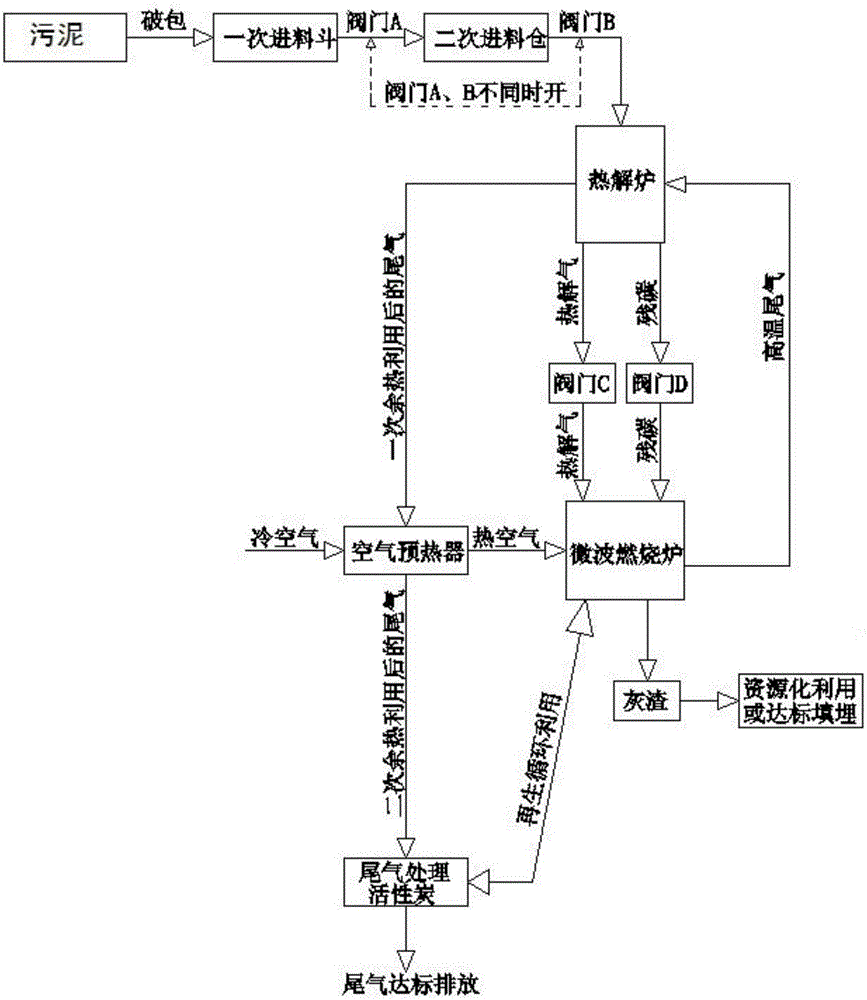

[0036] The sludge pyrolysis disposal method based on microwave quenching includes garbage feeding device, pyrolysis furnace, microwave combustion furnace, tail gas purification device and slag solid waste cleaning device. The entire pyrolysis incineration system is closed and under negative pressure. After the sludge is pulverized at the discharge port, it is sent to the pyrolysis furnace for pyrolysis, and the form of the pyrolysis furnace is a rotary kiln with mature technology. The pyrolysis gas produced in the rotary kiln is pumped by the fan to the air inlet on the top of the microwave oven, and then the pyrolysis gas is mixed with the air sent by another fan for combustion. The pyrolysis residual carbon falls on the high temperature plate in the microwave combustion furnace as a strong microwave-absorbing medium, and the residual carbon layer is heated to a temperature of 1200-1500 °C. The opening size of the high temperature plate meets the requirements for preventing mi...

Embodiment 2

[0038]A sludge pyrolysis treatment device based on microwave quenching, comprising: a feeding device, a pyrolysis device, a microwave combustion device, an exhaust gas purification device, a slag solid waste cleaning device, a fan, and an air preheater; the feeding device, The pyrolysis device, the microwave combustion device and the slag solid waste cleaning device are connected in sequence, and a gas circulation pipeline is also arranged between the pyrolysis device and the microwave combustion device; the pyrolysis device is also connected in sequence with the air preheater and the tail gas purification device When in use, the pyrolysis gas and pyrolysis residual carbon produced by the pyrolysis device are respectively input into the microwave combustion device through the fan and the material channel, and after full combustion, the high-temperature tail gas produced is returned to the pyrolysis device and the air preheater in turn . Tail gas purification device; the pyrolys...

Embodiment 3

[0041] A sludge pyrolysis treatment device based on microwave quenching, comprising: a feeding device, a pyrolysis device, a microwave combustion device, an exhaust gas purification device, a slag solid waste cleaning device, a fan, and an air preheater; the feeding device, The pyrolysis device, the microwave combustion device and the slag solid waste cleaning device are connected in sequence, and a gas circulation pipeline is also arranged between the pyrolysis device and the microwave combustion device; the pyrolysis device is also connected in sequence with the air preheater and the tail gas purification device When in use, the pyrolysis gas and pyrolysis residual carbon produced by the pyrolysis device are respectively input into the microwave combustion device through the fan and the material channel, and after full combustion, the high-temperature tail gas produced is returned to the pyrolysis device and the air preheater in turn . Tail gas purification device; the pyroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com