Tungsten rhenium thin-film temperature sensor cold-end compensating structure based on micro channel

A thin-film temperature and cold-junction compensation technology, which is applied to thermometers, thermometers with directly heat-sensitive electric/magnetic elements, instruments, etc., can solve the failure of the connection of the compensation wire of the thermocouple and the uncertainty of the temperature of the cold junction of the thermocouple Measurement, error and other problems, to improve accuracy and reliability, solve connection failure problems, improve heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

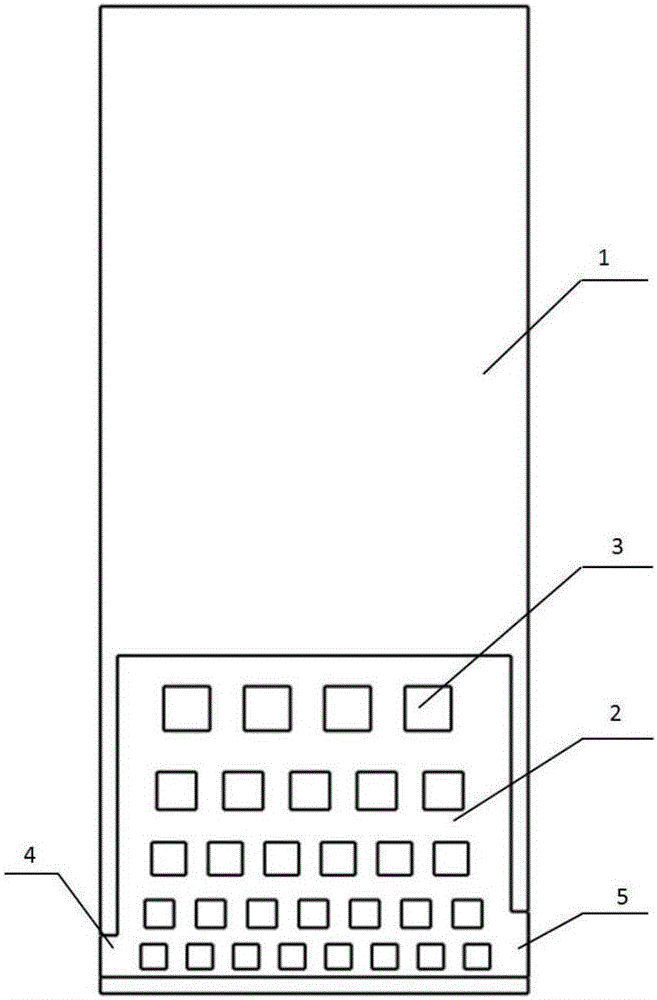

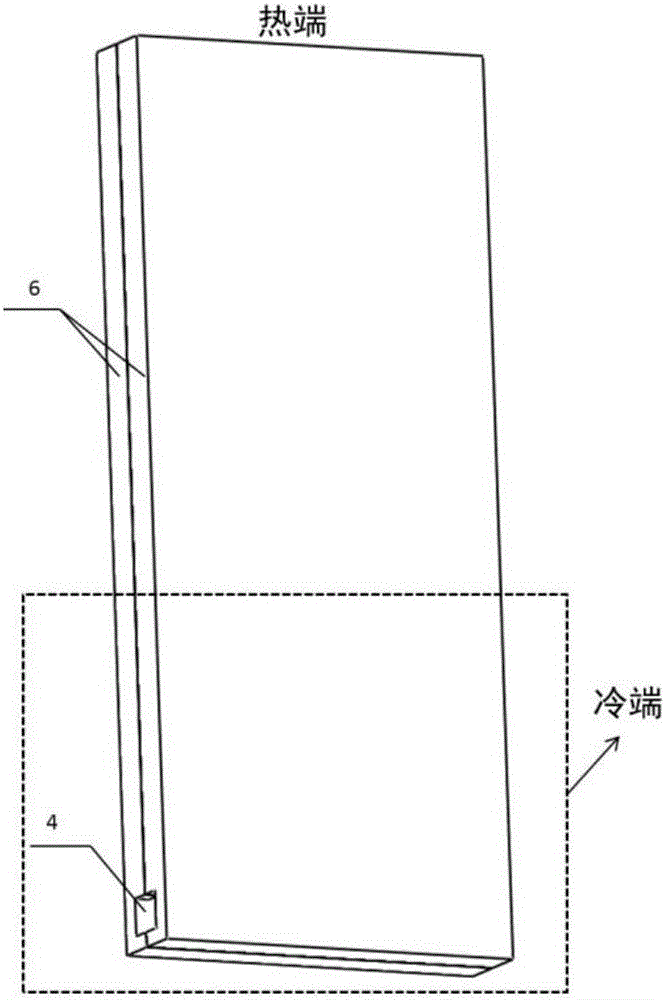

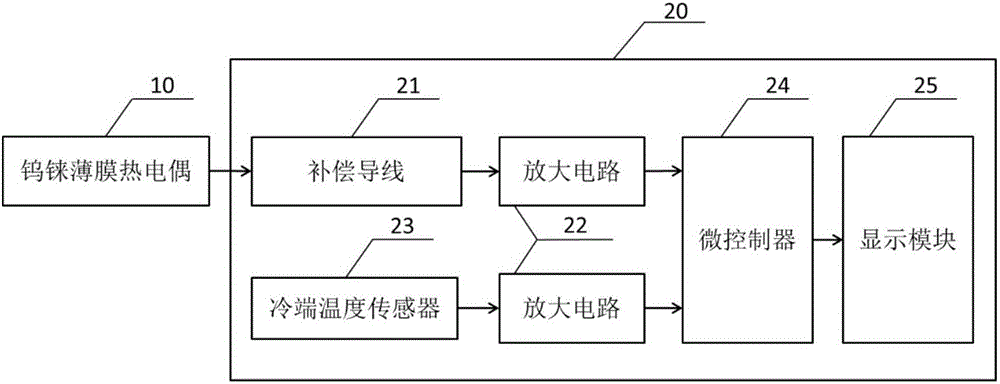

[0028] see Figure 1 to Figure 3 As shown, a cold junction compensation structure of a tungsten-rhenium thin film temperature sensor based on a microchannel in the present invention includes a tungsten-rhenium thin film thermocouple 10 and a cold junction temperature compensation module 20 .

[0029] The tungsten-rhenium thin-film thermocouple 10 includes a substrate 1 provided with a microchannel at the cold end of the thermocouple, and the microchannel at the cold end of the thermocouple is located on the cold end of the substrate 1. Needle fin 3, the size and density of pin fin 3 are not the same, the closer to the edge of the cold end, the smaller and denser the pin fin 3 is, the purpose is to effectively increase the flow resistance in the flow line area of the inlet and outlet of the flow channel, forcing the cold end The low-temperature working fluid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com