Phononic crystal structure and design method for ship vibration isolation

A phononic crystal and design method technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve unavailable problems, achieve the effect of enhancing robustness, ensuring joint strength and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will now be described in conjunction with the accompanying drawings, and the present invention is not limited to the following embodiments.

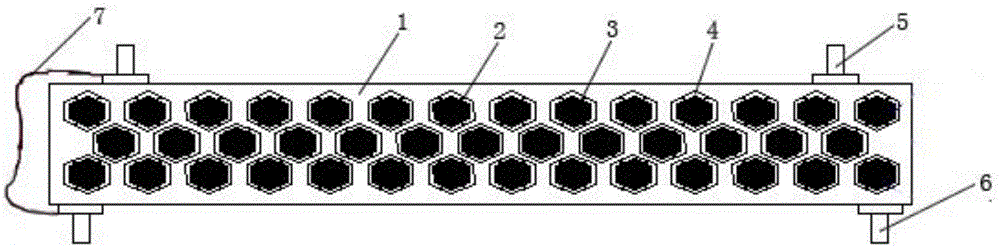

[0029] Such as figure 1 As shown, a phononic crystal structure used for ship vibration isolation includes a phononic crystal matrix 1, a spring 2 and a tungsten block 3. The phononic crystal matrix is a periodically distributed honeycomb structure, and the springs are symmetrically arranged on the inner wall of the honeycomb 4 On the top, the tungsten block is set in the inner cavity of the honeycomb, and the outer wall is in contact with the top of the spring. The four corners of the top surface and the bottom surface of the phononic crystal substrate are respectively provided with an upper connection block 5 and a lower connection block 6. The upper and lower connection blocks are grounded Connected to line 7 to meet the grounding requirements of ship equipment. The phononic crystal ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com