A kind of sheet laminated all-solid-state supercapacitor and preparation method thereof

A supercapacitor, all-solid-state technology, applied in the manufacture of hybrid/electric double layer capacitors, multiple hybrid/electric double layer capacitors, etc., can solve problems such as large performance differences, difficult large-scale components, easy leakage, etc., to achieve high reliability Sexuality and lifespan, use of space expansion, and overcoming the effect of short lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

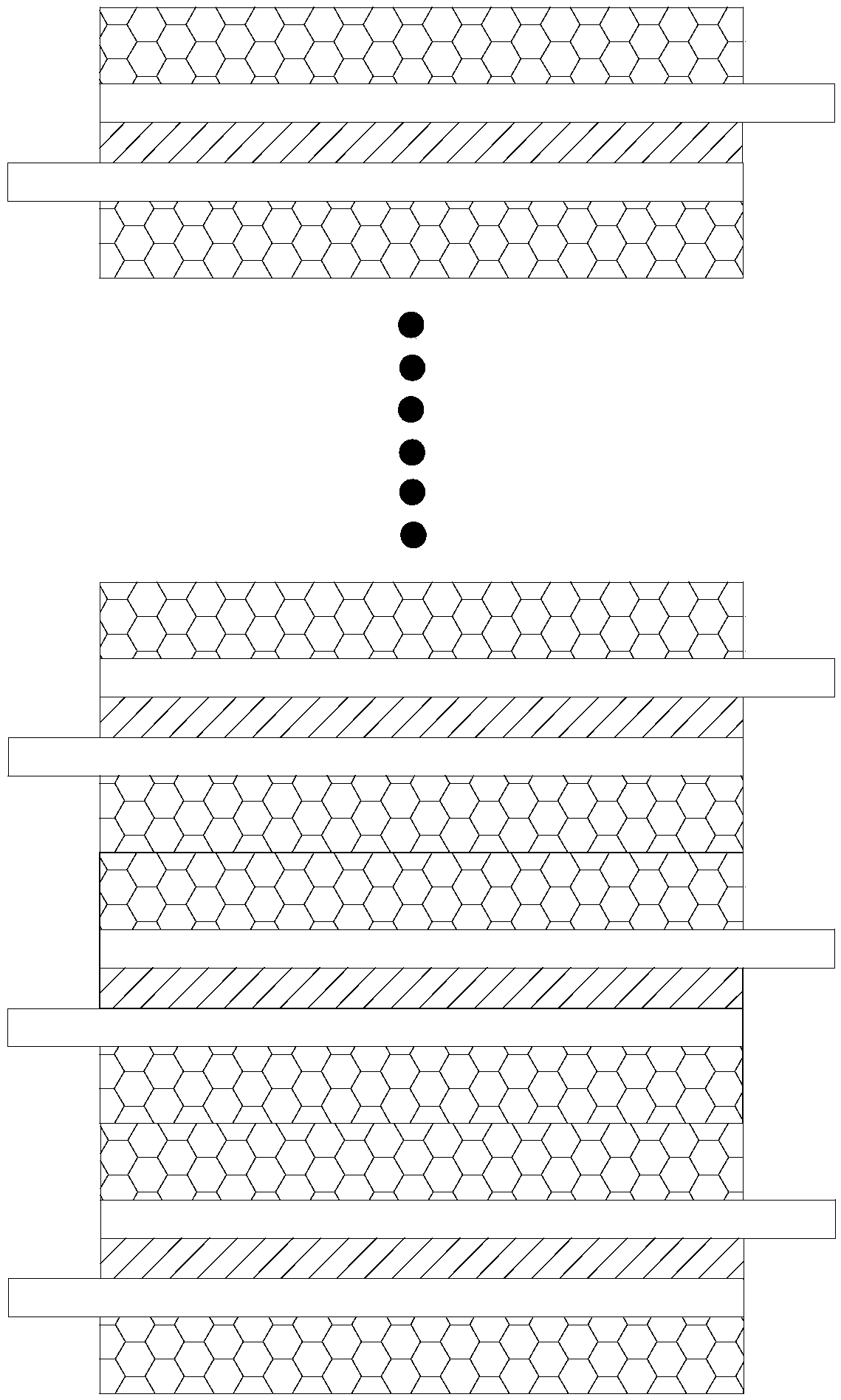

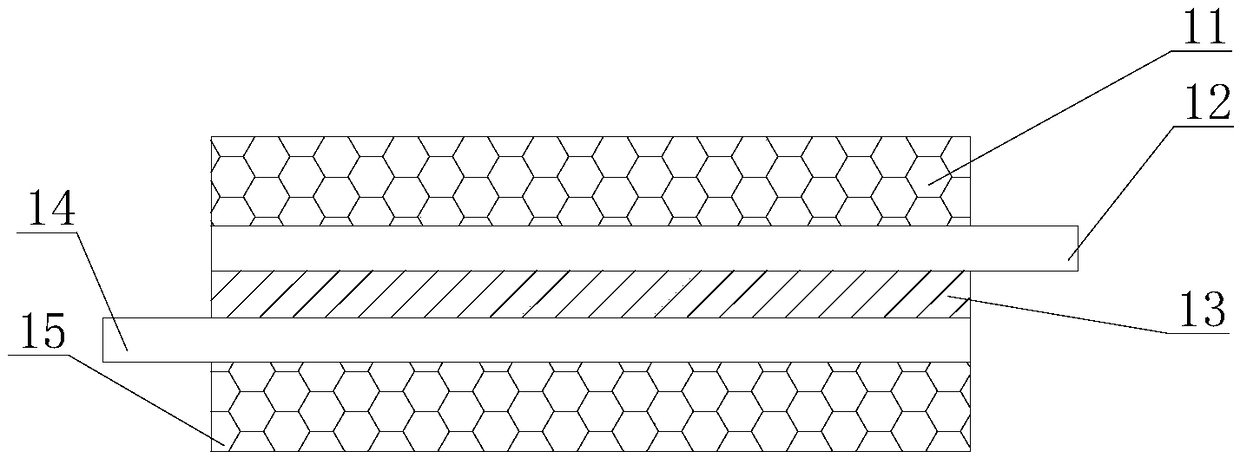

[0084] Such as image 3 Shown, a kind of laminated laminated all-solid supercapacitor comprises all-solid supercapacitor core 1 and casing 8,

[0085] The top side of the housing 8 is provided with a rectangular blind hole, and the opposite two inner walls of the rectangular blind hole are coated with conductive silver paste 9, and the upper surface of the housing 8 adjacent to the opposite two inner walls of the rectangular blind hole is also provided with a There is conductive silver paste 9,

[0086] The all-solid supercapacitor core 1 is clamped in the rectangular blind hole. The aluminum foils on both sides of the all-solid supercapacitor core 1 are in full contact with the conductive silver paste 9 on the inner side walls of the rectangular blind hole. The upper surface of the all-solid supercapacitor core 1 is also set There is an encapsulation layer,

[0087] The conductive silver paste 9 on both sides of the top side of the housing 8 is externally connected with an ...

specific Embodiment 2

[0124] Roughly the same as specific embodiment 1, the difference only lies in:

[0125] The shell 8 is a polymer shell.

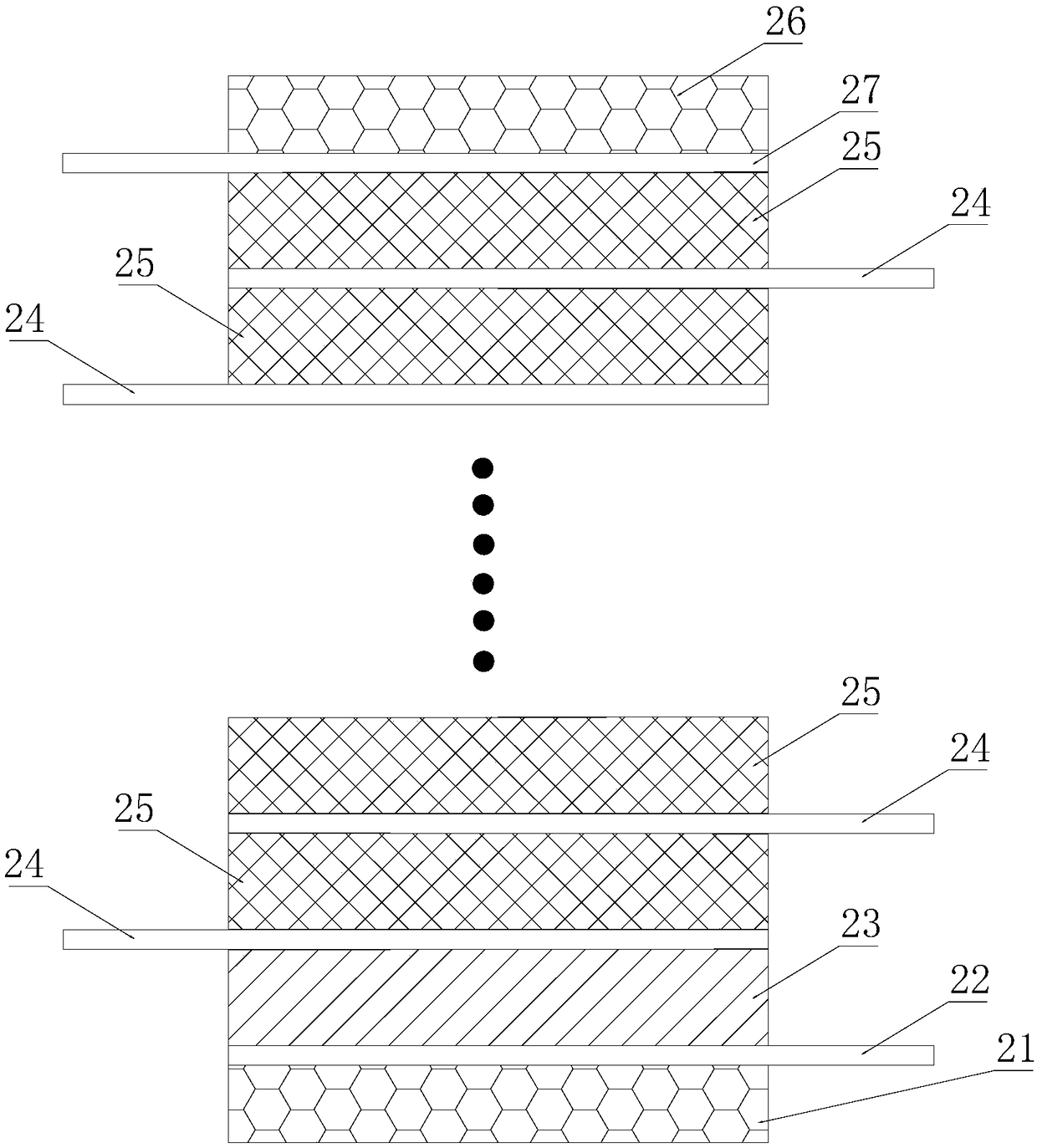

[0126] The laminated all-solid-state supercapacitor core with sheet-shaped double-sided electrodes is formed by bonding a sheet-shaped double-sided electrode.

[0127] Further, the first coating 13 includes dielectric / electrolyte composite powder and PVB,

[0128] The dielectric / electrolyte composite powder is made of BaTiO with a molar ratio of 2:1 3 Powder and β″-Al 2 o 3 mixed powder,

[0129] PVB accounts for 30% of the sum of the mass of dielectric / electrolyte composite powder and PVB.

[0130] Furthermore, BaTiO 3 The particle size of the powder is 50nm, β″-Al 2 o 3 The particle size of the powder is 50nm.

[0131] Further, step (1) includes the following steps:

[0132] (11), the BaTiO 3 Powder and β″-Al 2 o 3 After the powder is mixed at a molar ratio of 2:1, grind for at least half an hour, and pass through a 200-mesh sieve to obtain a...

specific Embodiment 3

[0139] Roughly the same as specific embodiment 1, the difference only lies in:

[0140] The first coating 13 includes dielectric / electrolyte composite powder and PVB,

[0141] The dielectric / electrolyte composite powder is made of BaTiO with a molar ratio of 1:2 3 Powder and β″-Al 2 o 3 mixed powder,

[0142] PVB accounts for 25% of the sum of dielectric / electrolyte composite powder and PVB mass.

[0143] Furthermore, BaTiO 3 The particle size of the powder is 40nm, β″-Al 2 o 3 The particle size of the powder is 40nm.

[0144] Further, step (1) includes the following steps:

[0145] (11), the BaTiO 3 Powder and β″-Al 2 o 3 After the powder is mixed at a molar ratio of 1:2, grind for at least half an hour, and pass through a 200-mesh sieve to obtain a dielectric / electrolyte composite powder;

[0146] (12), add appropriate amount of PVB to the composite powder that step (11) obtains, add alcohol while grinding for at least half an hour to form a uniform first coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com