Zinc tungstate/graphene composite material and preparation method and application thereof

A composite material and graphene technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as low specific capacity and poor safety, and achieve simple methods, excellent electrochemical performance, good rate performance and electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Add 40 mg GO to 20 mL deionized water and stir for 10 min, then transfer to an ultrasonic box for ultrasonic treatment for 2 h.

[0035] 2. Add 1mmol (298mg) Zn(NO 3 ) 2 6H 2 O aqueous solution 10mL, continue to stir for 4h.

[0036] 3. Slowly add 2mmol (660mg) Na 2 WO 4 2H 2 O 10mL aqueous solution, 10mL urotropine 50mg aqueous solution. Stir for 2h, transfer to the reaction kettle, and react at 200°C for 10h.

[0037] 4. Wash 3 times with alcohol, wash 3 times with water, and dry at 80°C for 5 hours to obtain ZnWO 4 @RGO.

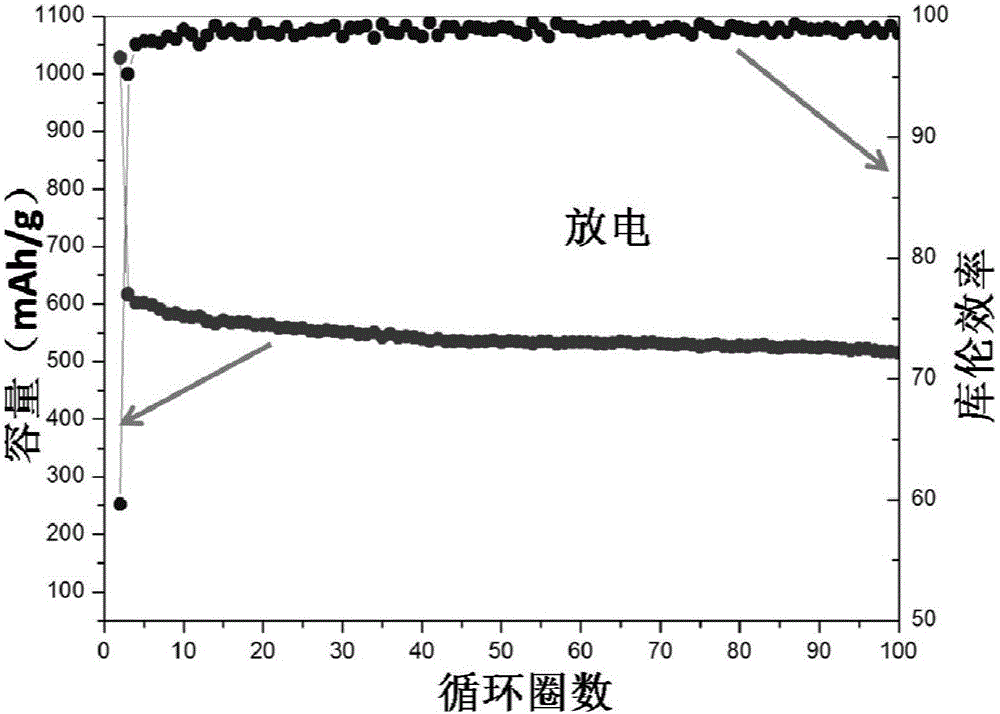

[0038] 5. Performance testing:

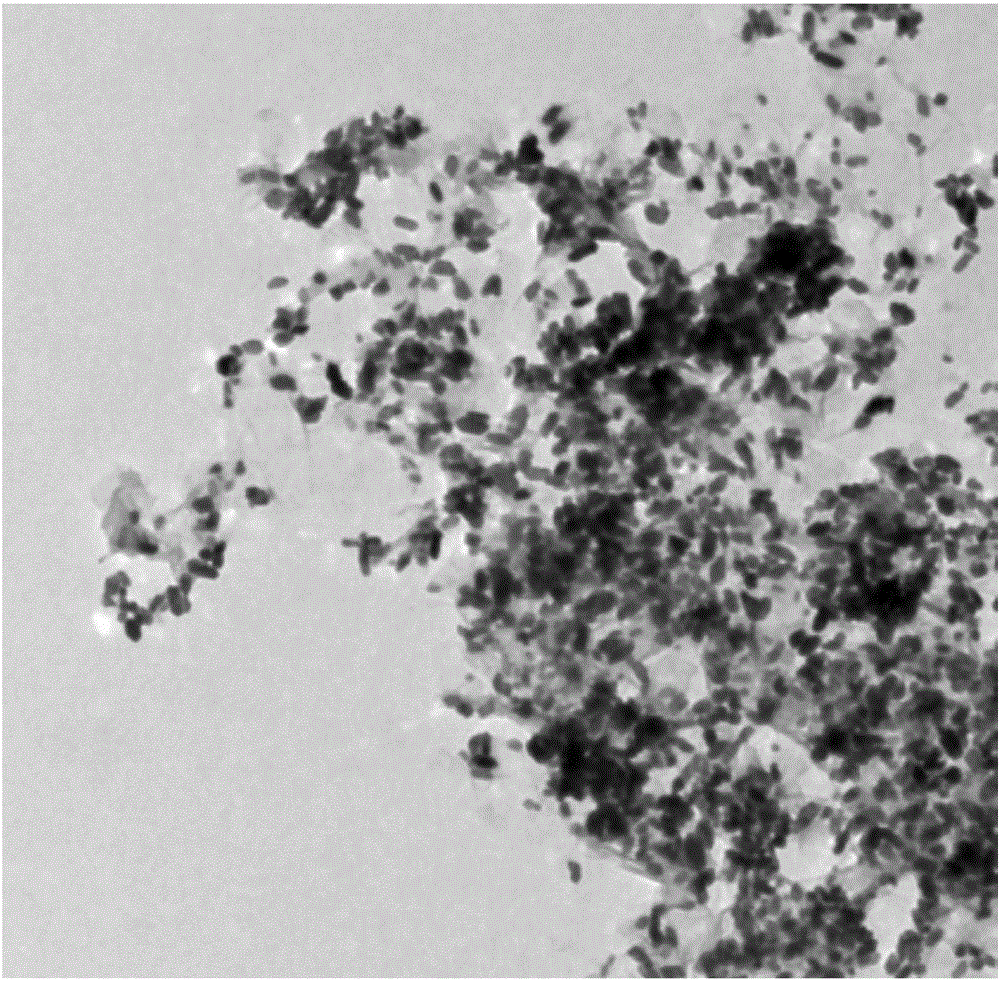

[0039] 5.1 Morphological characteristics: such as figure 1 As shown, zinc tungstate nanoparticles are evenly distributed on the surface of graphene, and the particle size is about 50nm.

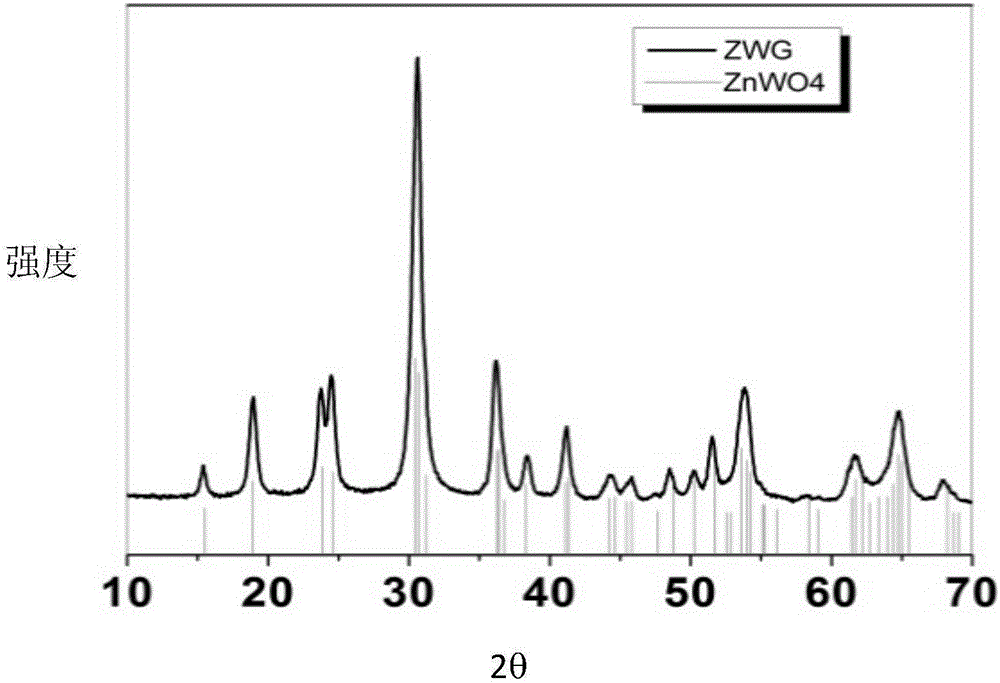

[0040] 5.2 Composition analysis: such as figure 2 As shown, ZnWO 4 The XRD of @RGO corresponds to the peaks of standard zinc tungstate, indicating that the complex is a complex of zinc tungstate and graphene with...

Embodiment 2

[0044] 1. Add 40mg GO to 20mL deionized water and stir for 10min, then transfer to an ultrasonic box for ultrasonic treatment for 2h.

[0045] 2. Add 1mmol (298mg) Zn(NO 3 ) 2 6H 2O aqueous solution 10mL, continue to stir for 4h.

[0046] 3. Slowly add 2mmol (660mg) Na 2 WO 4 2H 2 O 10mL aqueous solution, 170mg urotropine aqueous solution 10mL. Stir for 2h, transfer to the reaction kettle, and react at 200°C for 10h.

[0047] 4. Wash 3 times with alcohol, wash 3 times with water, and dry at 80°C for 5 hours to obtain ZnWO 4 @RGO.

[0048] 5. Performance testing:

[0049] 5.1 Morphological characteristics: such as Figure 4 As shown, the zinc tungstate is distributed on the graphene surface in the form of rods, the rods are 0.4 μm to 0.6 μm in length and about 80 nm in diameter.

[0050] 5.2 Composition analysis: such as Figure 5 As shown, ZnWO 4 The XRD of @RGO corresponds to the peaks of standard zinc tungstate, indicating that the complex is a complex of zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com