High-mach-number low-temperature array nozzle used for HF/DF chemical laser

A high Mach number, chemical laser technology, used in laser parts and other directions, can solve the problems of increased working pressure of the combustion chamber, unfavorable light output medium gain, loss of kinetic energy of the main nozzle, etc., to improve the gain, improve thermal dissociation efficiency, The effect of narrow boundary surface layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

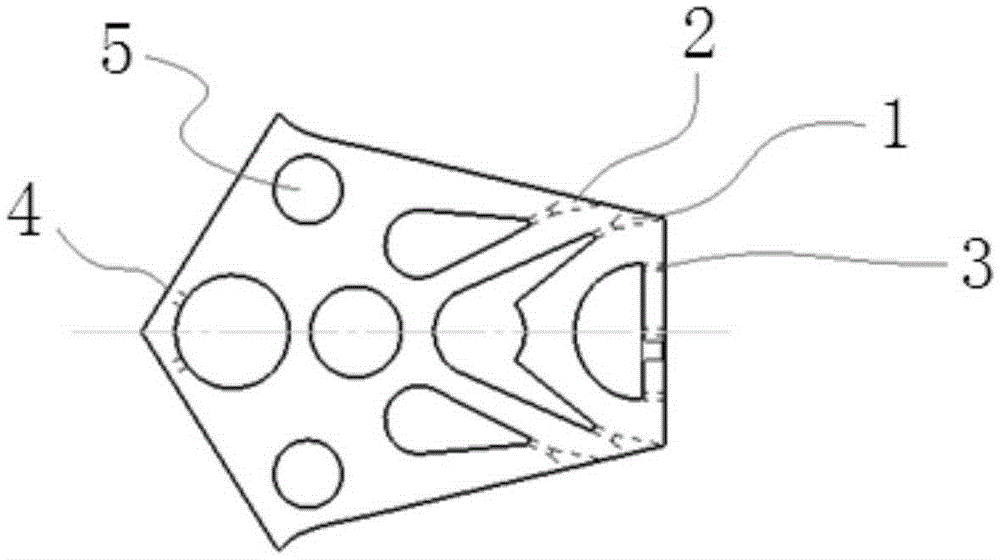

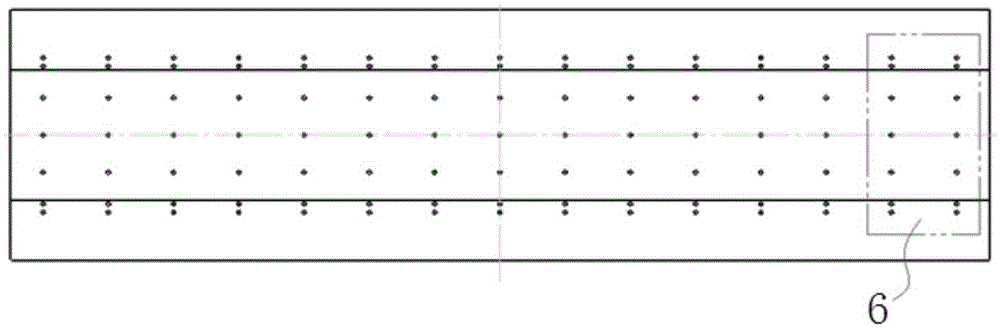

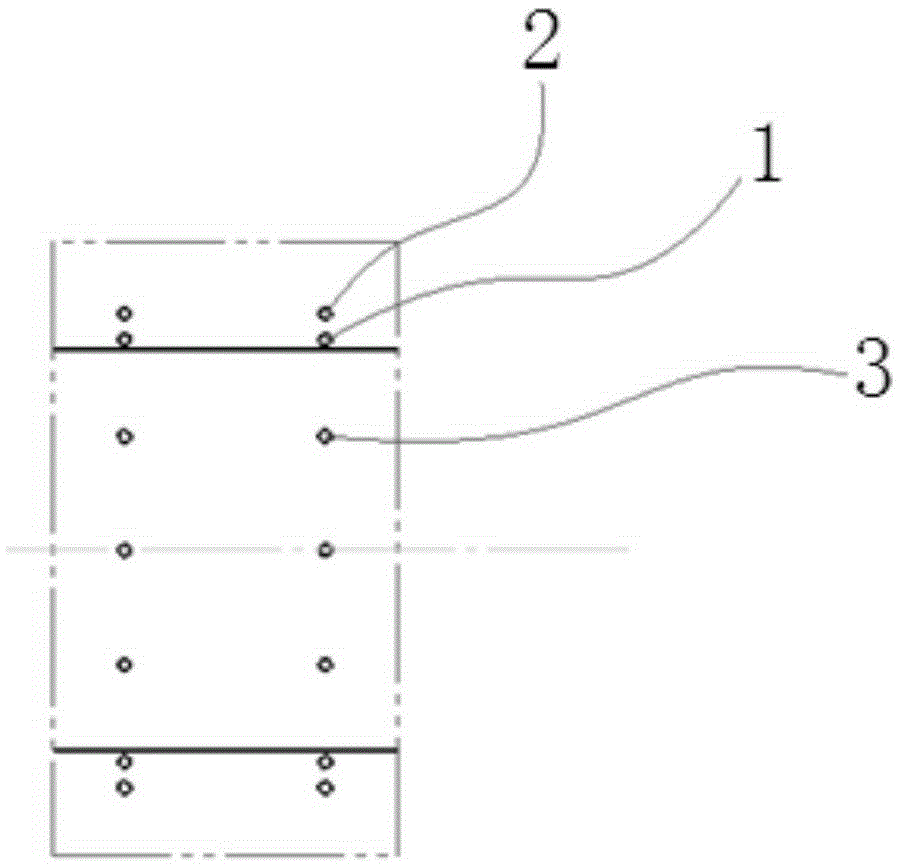

[0038] According to the design idea of the present invention, the following nozzles have been designed, and the nozzle assembly unit and the nozzle array assembly diagram are as follows:

[0039] Among them, the Mach number design value of the nozzle is 5.5; each nozzle unit is composed of two adjacent nozzle assembly units, the throat height is 0.2mm, and the profile dimensions of the inlet constriction section and outlet expansion section are determined by the hydrodynamic Calculated by the software, the outlet height is 9.5 mm; the distance between the hydrogen nozzle holes is 5 mm, and the center line of the hydrogen nozzle holes is parallel to the throat slit; the throat part of the hydrogen nozzle holes is a round hole with a diameter of 0.3 mm, and the outlet end is Circular conical hole with a diameter of 1mm at the exit; the main helium nozzle is just behind the hydrogen nozzle in the direction of the air flow, and the distance between the main helium nozzle and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com