DFB laser based on surface gating

A technology of DFB lasers and surface gratings, applied in lasers, semiconductor lasers, phonon exciters, etc., can solve the problems of complex etching process, large electrode loss, high cost, etc., achieve simple manufacturing process, reduce manufacturing cost, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

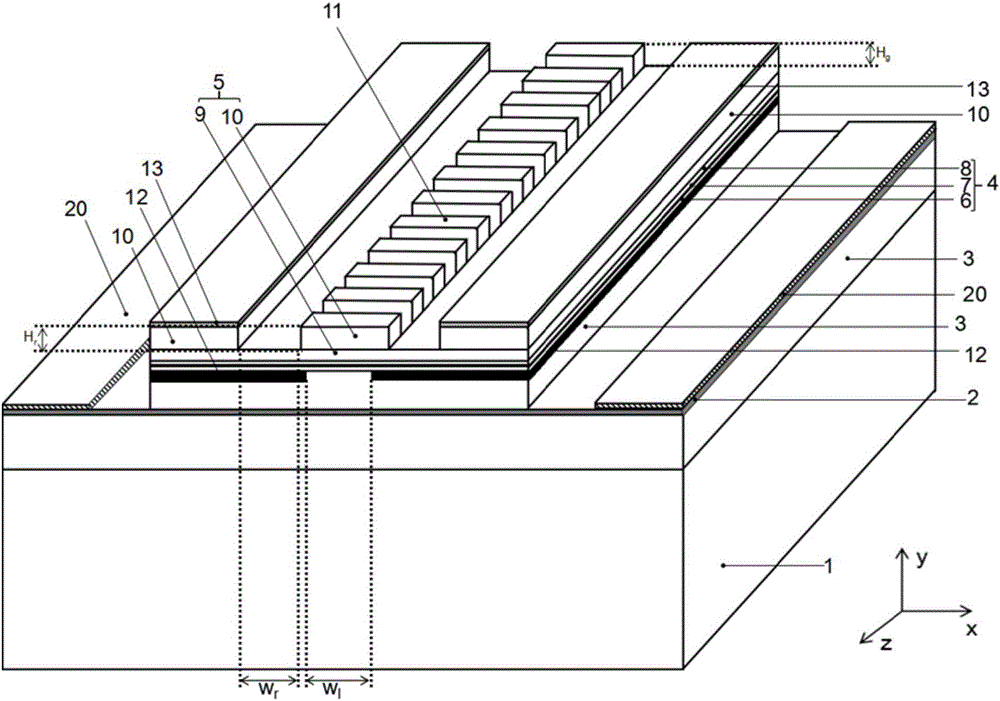

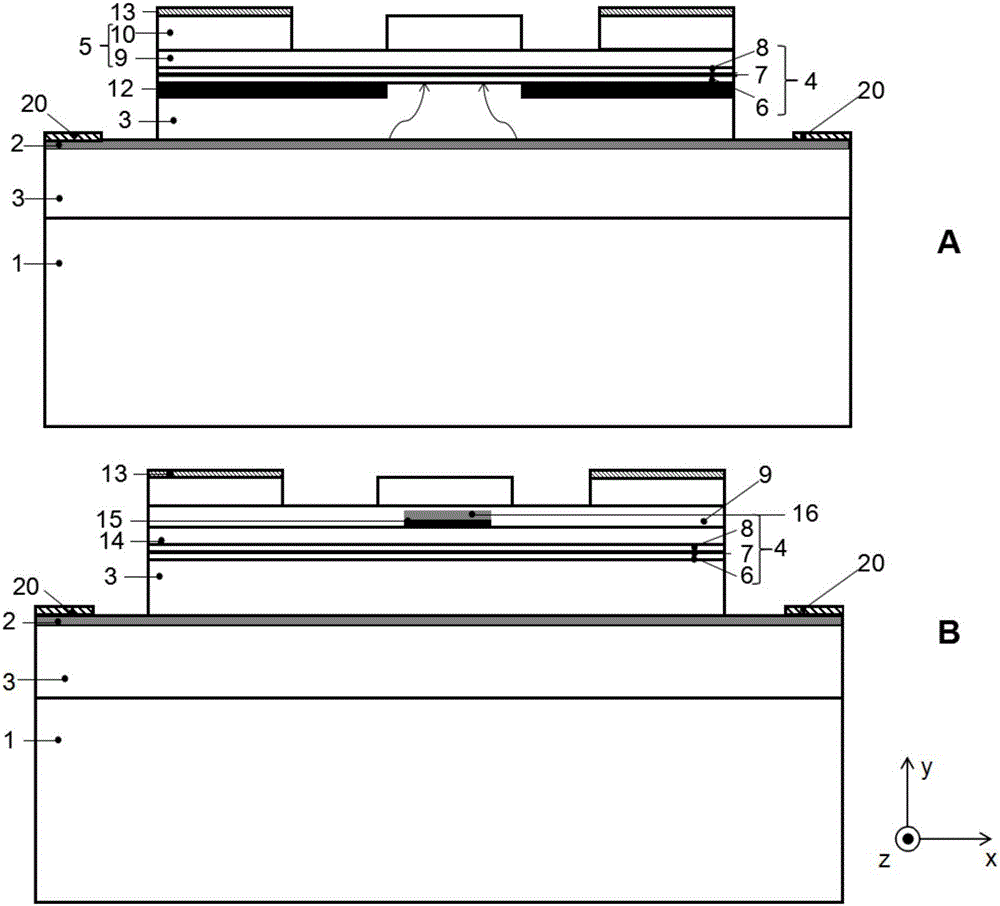

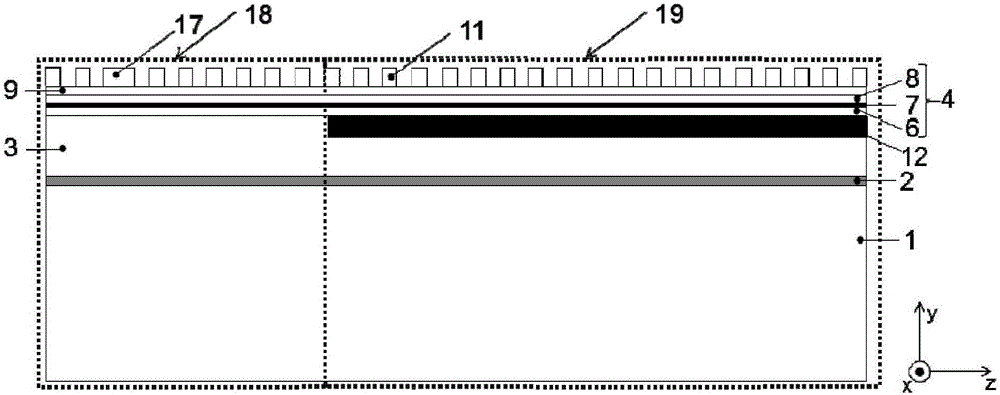

[0031] figure 1 is a schematic structural diagram of a surface grating-based DFB laser according to the present invention. The lateral, transverse and longitudinal directions of the laser are denoted as x, y and z directions, respectively, and all schematic diagrams use the same spatial coordinate system and labels. Such as figure 1 As shown, the layered structure of the semiconductor laser includes a substrate 1 , a lower waveguide capping layer 3 , an active layer 4 , and an upper waveguide capping layer 5 in a cross section from bottom to top. Among them, the lower waveguide cover layer 3 is P-type doped, the active layer 4 is not doped, the upper waveguide cover layer 5 is N-type doped, and the upper waveguide cover layer 5, the active layer 4 and the lower waveguide cover layer 3 jointly constitute N-i-P structure. From bottom to top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coupling coefficient | aaaaa | aaaaa |

| Coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com