Motor comprising HALBACH array and equipment comprising motor

An array and permanent magnet technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of permanent magnet damage, low torque density, complex processing, etc., and achieve the effect of reducing mass, reducing weight and improving torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

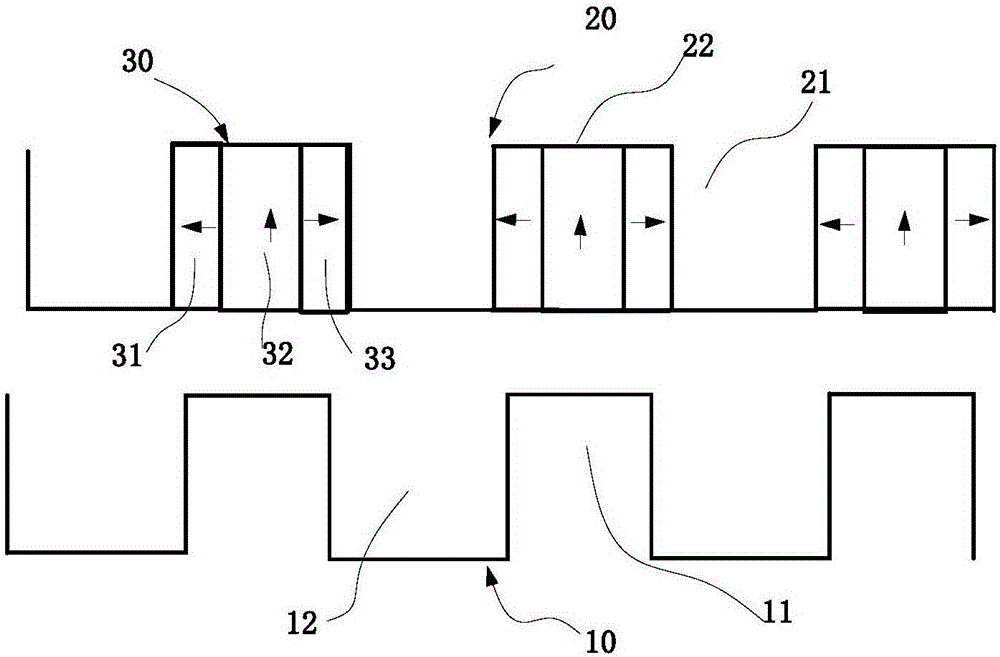

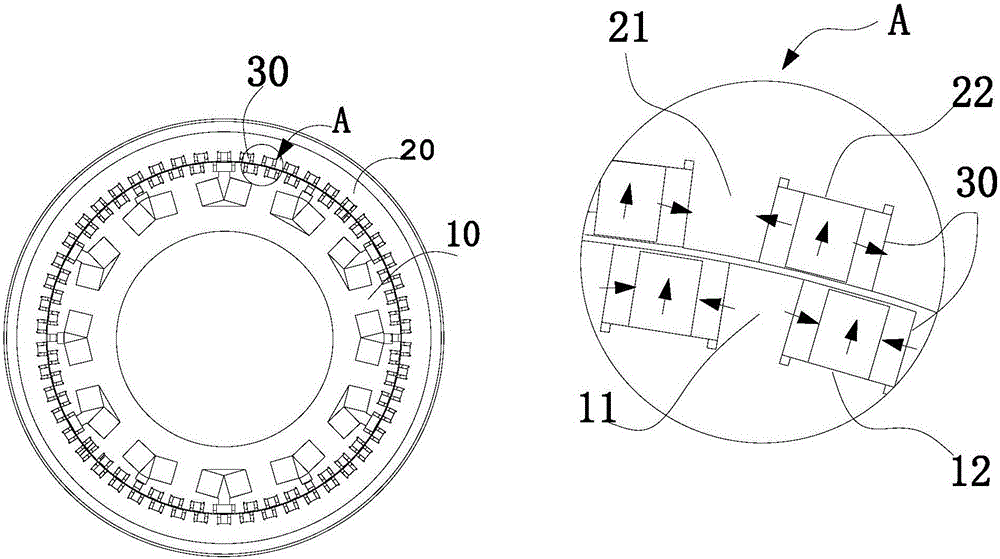

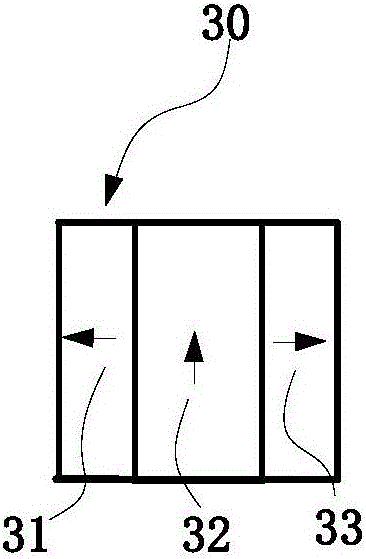

[0032] figure 1 A schematic diagram of a partial structure of a linear motor provided by an embodiment of the present invention; figure 2 It is a structural schematic diagram of a rotating electrical machine provided by an embodiment of the present invention, and the right side is an enlarged structural schematic diagram of part A.

[0033] In the field of permanent magnet motors, there are existing permanent magnet motors using HALBACH arrays. As described in the background, the opposing surfaces of the rotor and stator of the motor are surrounded by HALBACH arrays. The HALBACH array using this arrangement requires a plurality of permanent magnets with various magnetization directions to form together, and its processing is complicated, and the arrangement of this array requires the permanent magnets in the middle to be close to each other, so it is relatively difficult to assemble. Troublesome, and easy to cause damage to the permanent magnet.

[0034] Such as figure 1...

Embodiment 2

[0065] Embodiment 2 of the present invention also provides a device, which includes the motor described in Embodiment 1.

[0066] For the motor, refer to the description in Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com