Compressed air type drying machine for vegetable storage

A compressed air and dryer technology, applied in the direction of dryers, drying gas layout, application, etc., can solve the problems of images, easy to produce humid working environment, low drying efficiency, etc., achieve super large heat exchange area, good noise reduction effect, The effect of temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

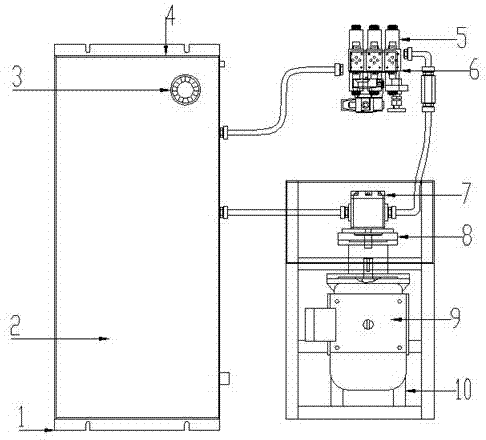

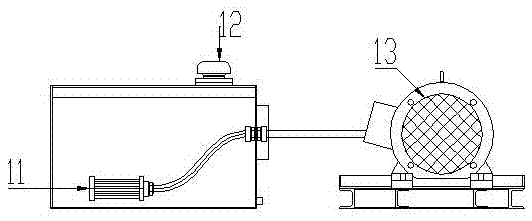

[0016] Such as Figure 1-Figure 2 As shown, a compressed air dryer for vegetable storage includes a base 1, a top shell 4, a sealing ring 8 and a compressor 11. A chassis 2 is arranged above the base 1 to provide high pressure. The switch knob 3 can control the switch. The switch knob 3 is set between the chassis 2 and the top shell 4 to adjust the internal balance. A pressure valve 5 is arranged above the top shell 4 to adjust the internal pressure. Below the pressure valve 5 A hydraulic bottle 6 is installed to increase the power. A motor 7 is arranged below the hydraulic bottle 6 to provide electric energy supply. The motor 7 is arranged above the sealing ring 8 for sealing. An air centrifuge 9 is installed below the sealing ring 8 to increase the power. Large air compression capacity, a support frame 10 is set under the air centrifuge 9, which can adjust the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com