Co-Fe alloy loaded carbon material and preparation method and application thereof

A carbon material and alloy technology, which is applied in the field of carbon materials supporting Co-Fe alloy and its preparation, can solve the problems of low maximum saturated adsorption capacity, poor adsorbent performance, and poor separation of waste water, etc., and achieves strong magnetic, Easy operation and high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

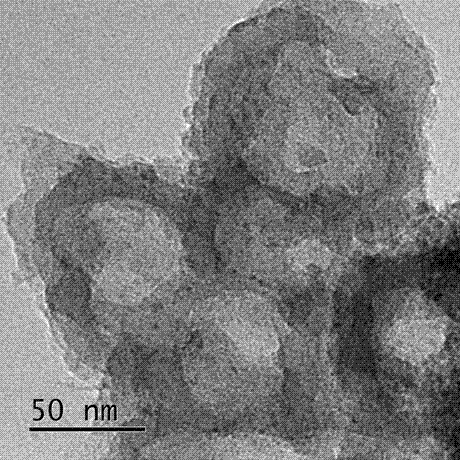

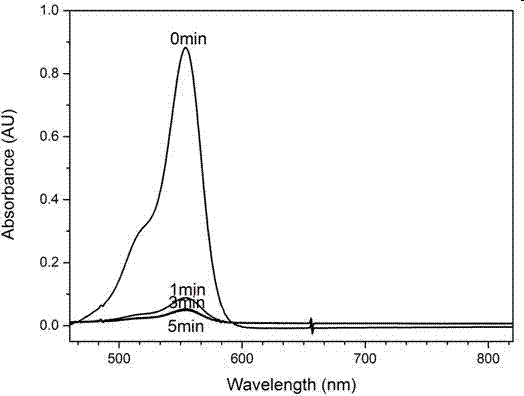

[0023] (1) Dissolve 1g of yellow-brown 1,1'-ferrocenecarboxylic acid powder and 1g of pink cobalt acetate tetrahydrate powder in 360mL of deionized water at room temperature, and stir until all solids are dissolved to obtain brown-red solution;

[0024] (2) Put the brown-red solution obtained in step (1) into a constant temperature magnetic stirring water bath, control the constant temperature of the water bath at 70°C, turn on the magnetic stirring, add dropwise sodium hydroxide solution (0.1M) during the stirring process, and adjust the concentration of the solution The pH is 6, after adding 1g of 1,10'-phenanthroline, stirring for 1h, a reddish-brown viscous liquid is obtained;

[0025] (3) Transfer the reddish-brown viscous liquid obtained in step (2) to a hydrothermal kettle, control the temperature at 45°C, heat the water for 50 hours, and after cooling to room temperature, pour out the suspension in the reaction kettle, and control the speed to 6000r / min, centrifuge to...

Embodiment 2

[0030] (1) Dissolve 1g of yellow-brown 1,1'-ferrocenecarboxylic acid powder and 5g of pink cobalt acetate tetrahydrate powder in 300mL of deionized water at room temperature, and stir until all the solids are dissolved to obtain brown-red solution;

[0031] (2) Put the brown-red solution obtained in step (1) into a constant temperature magnetic stirring water bath, control the constant temperature of the water bath at 30°C, turn on the magnetic stirring, add dropwise sodium hydroxide solution (0.3M) during the stirring process, and adjust the concentration of the solution pH is 4, stirring for 2h, a reddish-brown viscous liquid is obtained;

[0032] (3) Transfer the reddish-brown viscous liquid obtained in step (2) to a hydrothermal kettle, control the temperature at 100°C, heat the water for 48 hours, and after cooling to room temperature, pour out the suspension in the reaction kettle, and control the speed to 7000r / min, centrifuge to obtain a dark red solid, put it in an o...

Embodiment 3

[0035] (1) Dissolve 1g of yellow-brown 1,1'-ferrocenecarboxylic acid powder and 9g of pink cobalt acetate tetrahydrate powder in 400mL of deionized water at room temperature, and stir until all the solids are dissolved to obtain brown-red solution;

[0036] (2) Put the brown-red solution obtained in step (1) into a constant temperature magnetic stirring water bath, control the constant temperature of the water bath at 50°C, turn on the magnetic stirring, add dropwise sodium hydroxide solution (0.5M) during the stirring process, and adjust the concentration of the solution The pH is 12, after adding 1g of 1,10'-phenanthroline, stirring for 3 hours, a reddish-brown viscous liquid is obtained;

[0037] (3) Transfer the reddish-brown viscous liquid obtained in step (2) to a hydrothermal kettle, control the temperature at 200°C, heat the water for 72 hours, and after cooling to room temperature, pour out the suspension in the reaction kettle, and control the speed to 8000r / min, ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com