Wireless type flexible-arm vibration control system based on virtual instrument technology

A virtual instrument and vibration control technology, applied in the mechanical field, can solve problems such as cumbersome installation, errors, and many cables, and achieve the effects of solving inconvenient operation, improving transmission mode, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

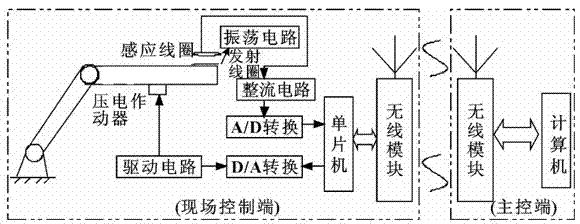

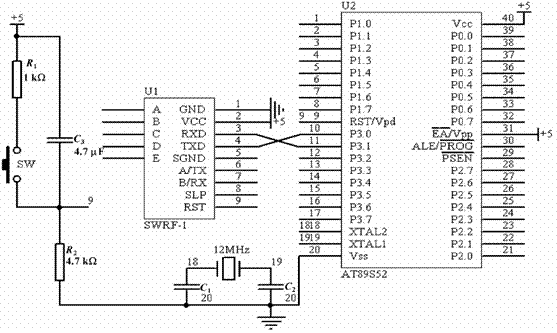

[0015] Such as figure 1 The on-site control terminal of the control system includes the drive of the stepping motor, the acquisition of vibration signals, A / D, D / A conversion, piezoelectric drivers, etc.; the main control terminal adopts LabVIEW software programming, which mainly completes the reception, processing and transmission of vibration data ; A pair of wireless data transmission modules are used to transmit the signals of the two control terminals, realizing wireless vibration control.

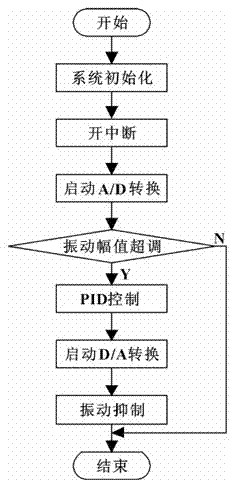

[0016] The working principle of the system is: the double-rod piezoelectric flexible arm is used as the control object, and the dual drive of piezoelectric ceramics and stepping motor is adopted. The stepping motor controls the rigid motion of the flexible arm, and the piezoelectric actuator controls the elastic vibration of the flexible arm. First, the movement of the stepper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com