Novel hybrid photovoltaic cell and preparation method thereof

A photovoltaic cell and hybrid technology, applied in the field of new hybrid photovoltaic cells and their preparation, can solve the problems of no significant improvement in organic solar cells, environmental risks, and high manufacturing costs, achieve excellent photoelectric conversion efficiency, and improve cost. The effect of excellent film properties and electrical conductivity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

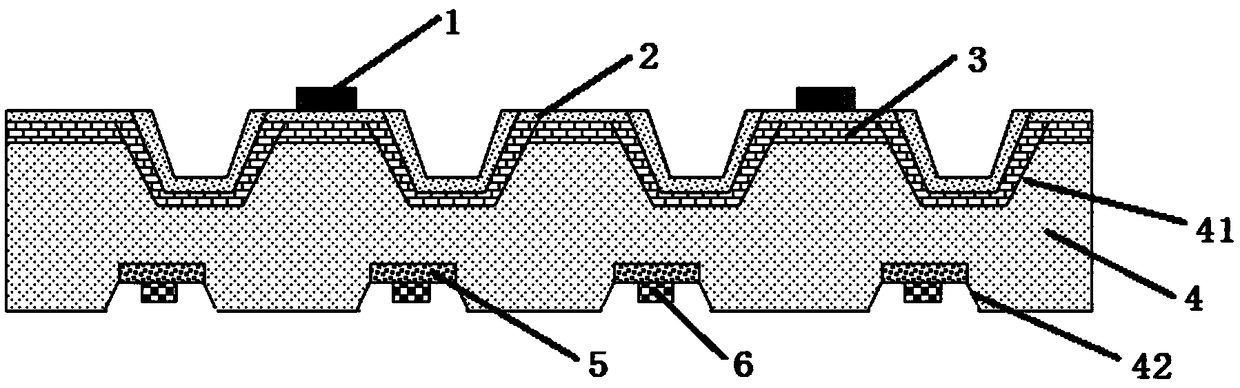

[0028] The present invention proposes a preparation method of a novel hybrid photovoltaic cell, comprising the following steps:

[0029] 1) An N-type silicon wafer is provided, the N-type silicon wafer is cleaned, and then a plurality of first grooves arranged in parallel and spaced apart are formed on the upper surface of the N-type silicon wafer, and then the N-type single crystal The lower surface of the silicon wafer forms a plurality of second grooves arranged in parallel and arranged at intervals. The second grooves correspond to each other one by one, and the first groove and the corresponding second groove partially overlap in the vertical direction, and the bottom surface of the first groove and the corresponding second groove The thickness between the bottom surfaces of the grooves is 100-200 microns, and the width of the overlapping portion of the bottom surface of the first groove and the bottom surface of the corresponding second groove in the vertical direction i...

Embodiment 1

[0044] A method for preparing a novel hybrid photovoltaic cell, comprising the following steps:

[0045] 1) An N-type silicon wafer is provided, the N-type silicon wafer is cleaned, and then a plurality of first grooves arranged in parallel and spaced apart are formed on the upper surface of the N-type silicon wafer, and then the N-type single crystal The lower surface of the silicon wafer forms a plurality of second grooves arranged in parallel and arranged at intervals. The second grooves correspond to each other one by one, and the first groove and the corresponding second groove partially overlap in the vertical direction, and the bottom surface of the first groove and the corresponding second groove The thickness between the bottom surfaces of the grooves is 150 microns, and the width of the overlapping portion of the bottom surface of the first groove and the bottom surface of the corresponding second groove in the vertical direction is equal to the bottom surface of the...

Embodiment 2

[0060] A method for preparing a novel hybrid photovoltaic cell, comprising the following steps:

[0061] 1) An N-type silicon wafer is provided, the N-type silicon wafer is cleaned, and then a plurality of first grooves arranged in parallel and spaced apart are formed on the upper surface of the N-type silicon wafer, and then the N-type single crystal The lower surface of the silicon wafer forms a plurality of second grooves arranged in parallel and arranged at intervals. The second grooves correspond to each other one by one, and the first groove and the corresponding second groove partially overlap in the vertical direction, and the bottom surface of the first groove and the corresponding second groove The thickness between the bottom surfaces of the grooves is 100 microns, and the width of the overlapping portion of the bottom surface of the first groove and the bottom surface of the corresponding second groove in the vertical direction is equal to the bottom surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com