Catalytic wet oxidation treatment method of sludge

A technology for catalytic wet oxidation and treatment methods, applied in water/sludge/sewage treatment, chemical instruments and methods, special treatment targets, etc., to achieve the effects of clarification of separated liquid, reduction of usage, and low turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

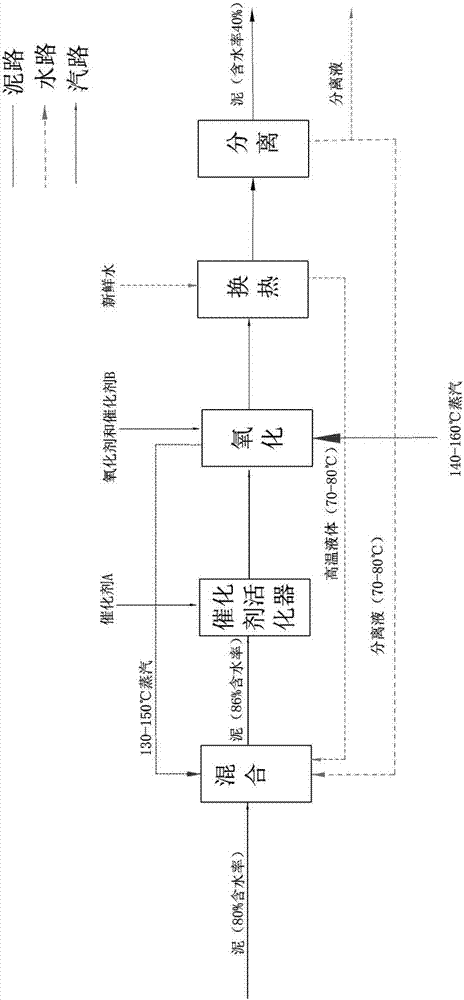

Image

Examples

Embodiment 1

[0040] Dewater the remaining sludge from the domestic sewage plant, control the moisture content of the sludge to 80%, and then pass it into the reaction system as the raw sludge for feeding. The organic matter content is 42%, and the daily treatment capacity is 100t.

[0041]Raw mud (dry weight 1000kg) and high temperature (75 ℃) separation liquid are mixed into the mud of moisture content 85%, inject hydrogen peroxide (27%) 500ml and catalyst A (ferrous ion 20kg) in catalyst activator as activator, Fully stir and oxidize for 40 minutes, the temperature of the mud rises to about 70°C due to oxidation, then the mud is pumped into the oxidizer, and the temperature is raised to 130°C by passing in steam. Due to the decomposition of hydrogen peroxide to produce oxygen, the instantaneous total pressure of the oxidation reactor can reach 2.5MPa, after the pressure is reduced (1.0~2.0MPa), feed oxygen and catalyst B (copper oxide 5kg), feed steam to raise the temperature to 145°C, st...

Embodiment 2

[0043] Dewater the remaining sludge from the domestic sewage plant, control the moisture content of the sludge to 75%, and then pass it into the reaction system as the raw sludge for feeding. The organic matter content is 45%, and the daily treatment capacity is 50t.

[0044] Raw mud (dry weight 1000kg) is mixed with high temperature (55°C) separation liquid to form a mud with a water content of 83%. Add ozone 20kg and catalyst A (5kg of cobalt ion) as activators in the catalyst activator, fully stir and oxidize for 20min, The mud temperature rises to about 65°C due to oxidation, and then the mud is pumped into the oxidizer, and the temperature is raised to 150°C by passing steam. Oxygen is produced due to the decomposition of ozone, and the instantaneous total pressure of the oxidation reactor can reach 2.5MPa. After the pressure drops ( 1.0~2.0MPa), feed oxygen and catalyst B (manganese oxide 80kg), feed steam to raise the temperature to 145°C, stay for 30 minutes, cool down ...

Embodiment 3

[0046] Dewater the remaining sludge from the domestic sewage plant, control the moisture content of the sludge to 70%, and then pass it into the reaction system as the raw sludge for feeding. The organic matter content is 43%, and the daily treatment capacity is 50t.

[0047] Raw mud (dry weight 1000kg) is mixed with high temperature (55°C) separation liquid to form a mud with a water content of 90%. Add ozone 300kg and catalyst A (cobalt ion 20kg) as activators to the catalyst activator, fully stir and oxidize for 30min, The temperature of the mud rises to about 65°C due to oxidation, and then the mud is pumped into the oxidizer, and the temperature is raised to 140°C by passing steam. Due to the decomposition of hydrogen peroxide to produce oxygen, the instantaneous total pressure of the oxidation reactor can reach 2.5MPa. After the pressure drops (1.0~2.0MPa), feed oxygen and catalyst B (alumina 5kg), feed steam to raise the temperature to 150°C, stay for 20min, cool down to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com