Preparation method of silicon carbide-based composite material mechanical sealing sliding part

A technology of mechanical seals and sliding parts, which is applied in the direction of mechanical equipment, engine seals, engine components, etc., can solve the problems of high production cost, uneven distribution of lubricating medium, long process cycle, etc., and achieve good sliding performance and sealing performance, Effects of improving sliding performance and sealing performance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

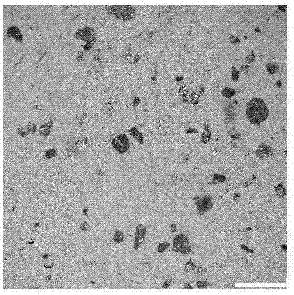

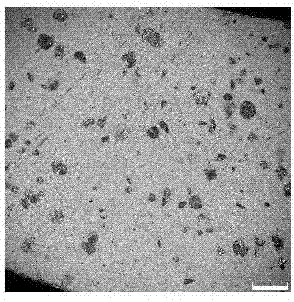

Image

Examples

Embodiment 1

[0041] Example 1: A method for preparing a silicon carbide-based composite material mechanical seal sliding part, which is to prepare a carbon mixture first, then mix the carbon mixture with pressureless sintered silicon carbide powder, sinter the mixture to form a blank, and then The blank is ground and processed into a finished product. After research, the applicant found that in the prior art, when various improvements are made to the sealed sliding parts containing silicon carbide, the silicon carbide raw material is generally firstly mixed with other additives, as shown in the first In the first) step of the first patent document (the application publication number is CN103641482A), the submicron α-type silicon carbide, boron carbide, resin, organic binder and lubricant are directly put into the mixer and pure water is added for Wet mixing; in the first) step of the second patent document (the application publication number is CN103922743A), the submicron α-type silicon c...

Embodiment 2

[0063] Embodiment 2: compared with embodiment 1, difference is: the preparation steps of carbon mixture are:

[0064]a. According to parts by weight, take 20 parts of graphite powder and 2.5 parts of dry powder binder, put the dry powder material composed of the above graphite powder and dry powder binder into the mixing tank, seal it and mill it on a ball mill for 80 minutes, and mix thoroughly Then pour into the kneader;

[0065] b. Start the kneader and start stirring for 80 minutes and gradually increase the temperature of the kneader to 112°C, evaporate the water in the dry powder, and then gradually lower the temperature to 82°C;

[0066] c. In parts by weight, take 9 parts of resin (preferably phenolic resin), 4 parts of alcohol, and 0.5 part of oleic acid, add the above materials into the container and stir evenly to form a resin adhesive, and then pour the resin adhesive into the kneader At this time, control the temperature of the kneader at 53°C, fully knead and st...

Embodiment 3

[0074] Embodiment 3: compared with embodiment 1, difference is: the preparation steps of carbon mixture are:

[0075] a. In parts by weight, take 30 parts of graphite powder and 3.5 parts of dry powder binder, put the dry powder material composed of the above graphite powder and dry powder binder into a mixing tank, seal it and mill it on a ball mill for 90 minutes, and mix thoroughly Then pour into the kneader;

[0076] b. Start the kneader and start stirring for 90 minutes, and gradually raise the temperature of the kneader to 115°C, evaporate the water in the dry powder, and then gradually lower the temperature to 85°C;

[0077] c. In parts by weight, take 11 parts of resin (preferably phenolic resin), 5 parts of alcohol, and 0.8 part of oleic acid, add the above materials into a container and stir evenly to form a resin adhesive, and then pour the resin adhesive into a kneader At this time, control the temperature of the kneader at 57°C, fully knead and stir the resin adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com