Synthesis method of amikacin

A technology of amikacin and synthesis method, which is applied in the field of medicine, can solve problems such as employee health damage, environmental hazards, and environmental hazards, and achieve the effects of reducing employee health damage, shortening reaction time, and increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

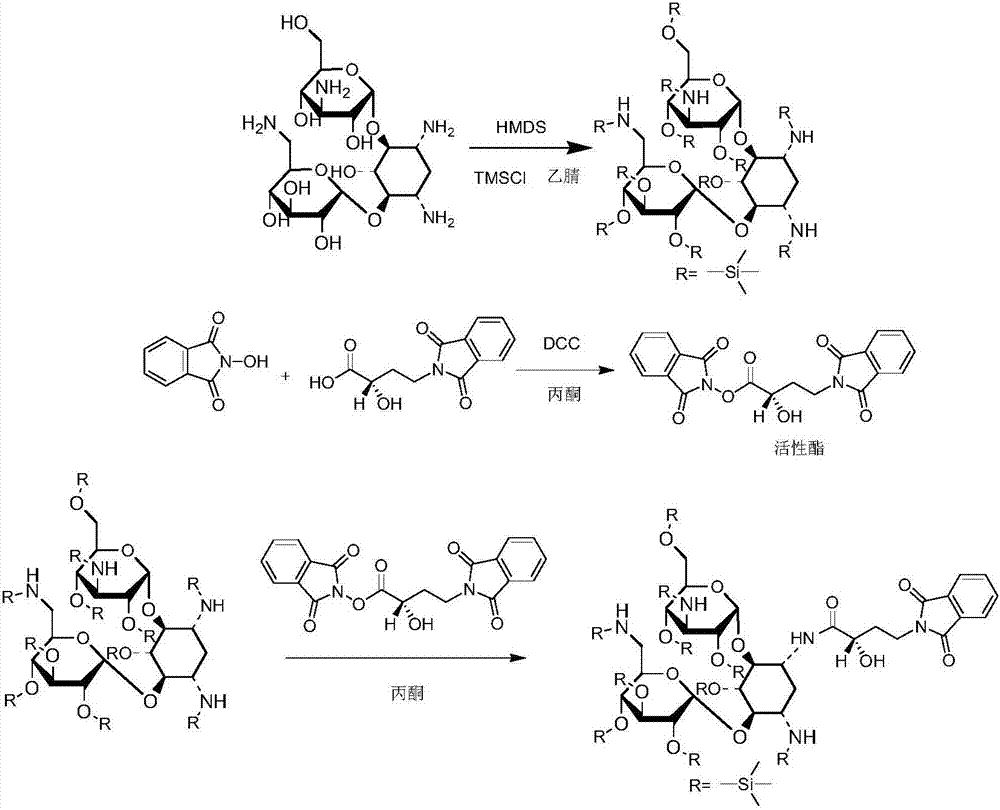

Method used

Image

Examples

Embodiment 1

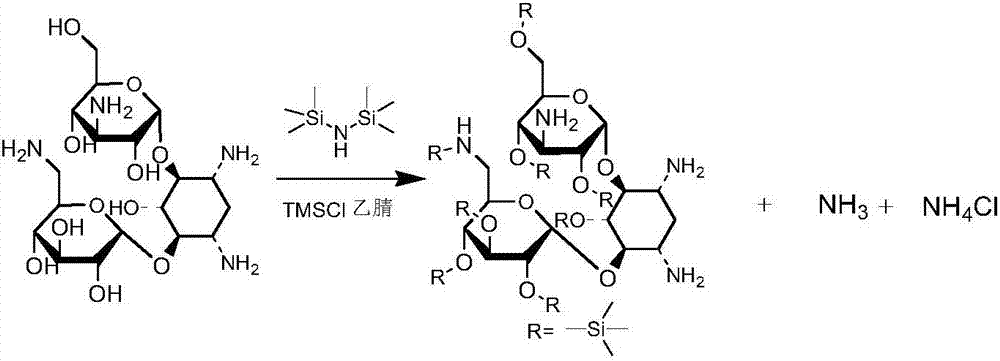

[0043] 1) Weigh 48.5g (0.1mol) of kanamycin A, add 460ml of acetonitrile, 115ml of hexamethyldisilazane, 1ml of trimethylchlorosilane, reflux for 5 hours, and detect after the liquid becomes clear Density ρ=1.03g / ml, spray-dried to obtain 101.2g of powdered silanized compound;

[0044]2) Add the above-mentioned powdered silanized compound, 27.4g of PHBA, and 600ml of acetone to a 1000ml three-necked flask, stir for 30 minutes to dissolve, cool down to -20°C, add 50ml of acetone solution containing 19.4g of DCC in 1 minute, and continue the reaction for 30 minutes Acylated products are obtained;

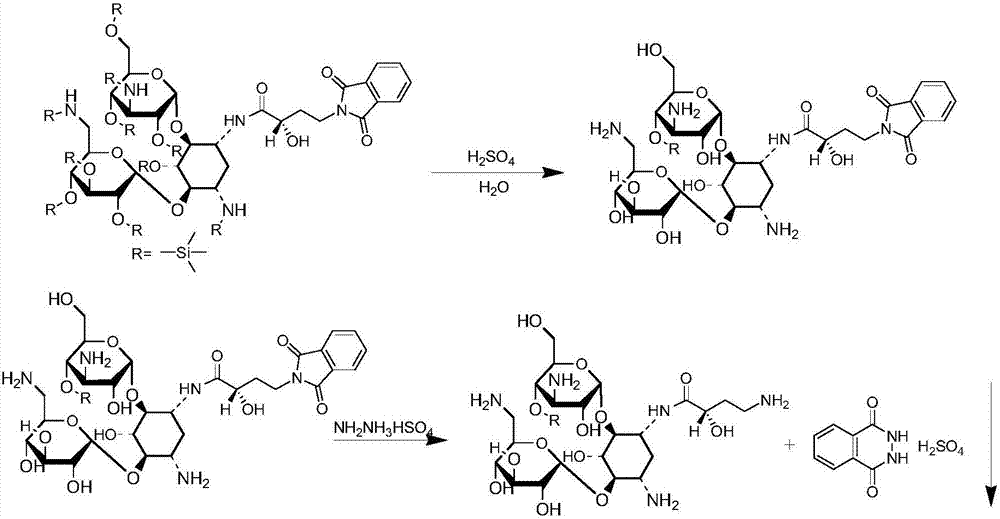

[0045] 3) adding concentrated hydrochloric acid to the above-mentioned acylated product to adjust the pH to 2.34, stirring and reacting for 1 hour, and distilling off the solvent under reduced pressure to obtain a hydrolyzed product of kanamycin;

[0046] 4) Add a small amount of water to the above-mentioned feed liquid, control the optical rotation of the feed liquid to α=55.6, lowe...

Embodiment 2

[0048] 1) Weigh 48.5g (0.1mol) of kanamycin A, add 460ml of acetonitrile, 115ml of hexamethyldisilazane, 1ml of trimethylchlorosilane, reflux for 5.5 hours, and detect after the liquid becomes clear Density ρ=1.04g / ml, spray-dried to obtain 103.5g;

[0049] 2) Add the above-mentioned powdered silanized compound, 28.0g of PHBA, and 600ml of acetone into a 1000ml three-necked flask, stir for 30 minutes to clear the whole, cool down to 0°C, add 50ml of acetone solution containing 20.6g of DCC in 1 minute, and continue the reaction for 30 minutes to obtain Acylation products;

[0050] 3) adding concentrated hydrochloric acid to the above-mentioned acylated product to adjust the pH to 2.34, stirring and reacting for 1 hour, and distilling off the solvent under reduced pressure to obtain a hydrolyzed product of kanamycin A;

[0051] 4) Add a small amount of water to the above-mentioned feed liquid, control the optical rotation of the feed liquid to α=55.6, lower the temperature to ...

Embodiment 3

[0053] 1) Weigh 48.5g (0.1mol) of kanamycin A, add 460ml of acetonitrile, 115ml of hexamethyldisilazane, 1ml of trimethylchlorosilane, reflux for 5 hours, and detect after the liquid becomes clear Density ρ=1.02g / ml, spray-dried to get 101.0g;

[0054] 2) Add the above-mentioned powdered silanized compound, 27.4g of PHBA, and 600ml of acetone to a 1000ml three-necked flask, stir for 30 minutes to clear the whole, cool down to -20°C, add 50ml of acetone solution containing 19.4g of DCC in 1 minute, and continue the reaction for 30 minutes Acylated products are obtained;

[0055] 3) adding concentrated hydrochloric acid to the acylated product to adjust the pH to 2.34, stirring for 1 hour, and distilling off the solvent under reduced pressure to obtain a hydrolyzed product of kanamycin A;

[0056] 4) Add a small amount of water to the above-mentioned feed liquid, control the optical rotation of the feed liquid α=55.6, lower the temperature to 20°C, add 20.2g of 80% hydrazine hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com