Low haze, high heat resistant and base coat-free PBT composite material and preparation method thereof

A composite material, high heat resistance technology, applied in the field of modified materials and materials, can solve the problem of inability to meet the high heat resistance requirements of automotive lamp decoration parts, and achieve the improvement of surface fogging and flooding phenomenon, good surface finish, Solve the effect of surface fogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

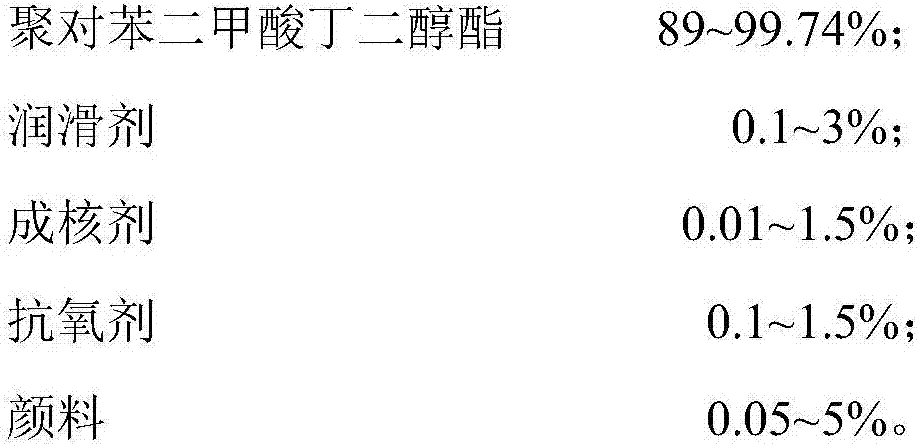

[0036] Adopt the following components by weight percentage among the present embodiment: polybutylene terephthalate (PBT) 90.5%, pentaerythritol stearate 3%, talcum powder 0.5%, β-(3,5-di-tert-butyl 1.0% stearyl-4-hydroxyphenyl) propionate, 5.0% carbon black. Each component of above-mentioned ratio is added in the high-speed batching mixer, high-speed mixing 1 minute; The premixed material after mixing is placed in twin-screw through melt extruding granulation, and the screw aspect ratio of twin-screw extruder is 36: 1. The number of vacuum ports is 1, and the extrusion process is: Twin-screw machine temperature zone: first-stage temperature 210°C, second-stage temperature 240°C, third-stage temperature 240°C, fourth-stage temperature 240°C, fifth-stage temperature 240°C , The head temperature is 250°C; the vacuum degree is -0.03MPa; the screw speed is 300rpm / min; the pelletizer speed: 300r / min; The particles are packaged to produce low haze, high heat resistance, and primer-...

Embodiment 2

[0038] The following components by weight percentage are used in this embodiment: 90.5% polybutylene terephthalate (PBT), 3% pentaerythritol stearate, 0.5% talcum powder, tetrakis[β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 1.0%, carbon black 5.0%. Add each component of the above ratio into a high-speed batching mixer, and mix at a high speed for 1 minute; place the mixed premix in a twin-screw and granulate through melt extrusion, and the screw length-to-diameter ratio of the twin-screw extruder is 40: 1. The number of vacuum ports is 1, and the extrusion process is: Twin-screw machine temperature zone: first-stage temperature 210°C, second-stage temperature 240°C, third-stage temperature 240°C, fourth-stage temperature 240°C, fifth-stage temperature 240°C , The head temperature is 250°C; the vacuum degree is -0.05MPa; the screw speed is 300rpm / min; the pelletizer speed: 300r / min; The particles are packaged to produce low haze, high heat resistance, and...

Embodiment 3

[0040] In this embodiment, the following components by weight percentage are used: 90.5% polybutylene terephthalate (PBT), 3% pentaerythritol stearate, 0.5% talcum powder, N,N'-1,6- Hexyl-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide 1.0%, color masterbatch 5.0%. Each component of above-mentioned proportion is added in the high-speed batching mixer, high-speed mixing 1 minute; The premixed material after mixing is placed in twin-screw through melt extruding granulation, and the screw length-diameter ratio of twin-screw extruder is 48: 1. The number of vacuum ports is 2, and the extrusion process is: twin-screw machine temperature zone: first-stage temperature 210°C, second-stage temperature 240°C, third-stage temperature 240°C, fourth-stage temperature 240°C, fifth-stage temperature 240°C , The head temperature is 250°C; the vacuum degree is -0.1MPa; the screw speed is 400rpm / min; the pelletizer speed: 400r / min; The particles are packaged to produce low haze, high heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com