Colored fadable water-based spraying paint

A water-based and colorful technology, applied in the field of spray paint, can solve the problems that it can only be used in wood, plastic and metal, harm the environment and human body, and cannot be automatically eliminated or quickly eliminated artificially, so as to achieve good environmental performance and anti-corrosion Good, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

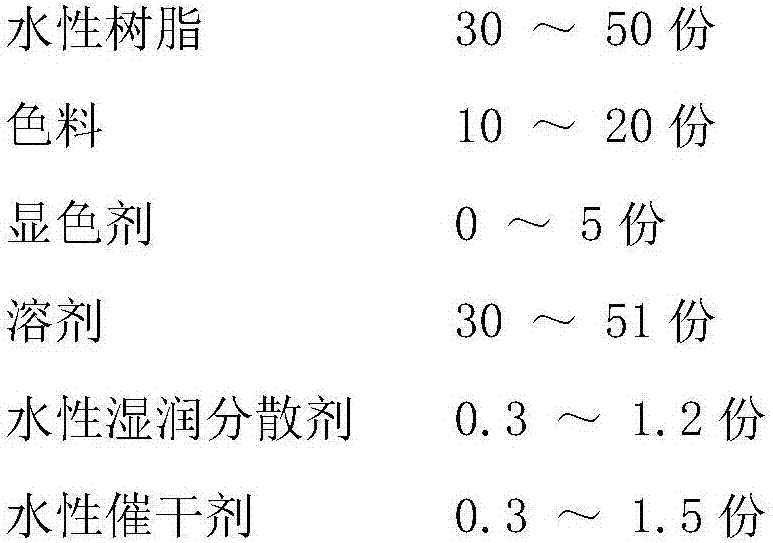

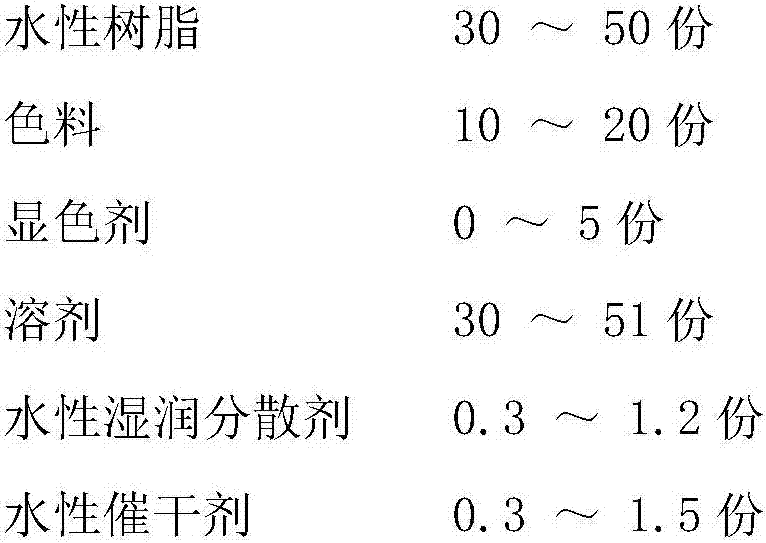

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: preparation of white spray paint

[0022] Put 20 parts of water-based acrylic resin HD1093 and 1.2 parts of water-based wetting and dispersing agent into the reactor, and disperse evenly at 600r / min, then add 15 parts of nerolidol, and disperse at 1200r / min for 20 minutes at a high speed; 12 parts of water-based resin, 50 parts of solvent (by mass ratio: 50 parts of ethanol, 20 parts of n-butanol, 27 parts of deionized water, 3 parts of propylene glycol methyl ether) and 0.6 parts of water-based drier SC- 1. Continue to stir for 20 minutes to prepare water-based spray paint. Put the spray paint and DME in a weight ratio of 1.2:1 into an aerosol can equipped with a valve and a press head to obtain a water-based spray paint.

Embodiment 2

[0023] Embodiment 2: preparation of red spray paint

[0024] 30 parts of water-based alkyd resin HK1045-65, 0.5 parts of water-based wetting and dispersing agent, 1.2 parts of bisphenol A and 15 parts of red material 3,3-bis(N-octyl-2-methylindole) phthalate A lactone was put into the reaction kettle, dispersed evenly at 600r / min, then 10 parts of nerolidol was added, and dispersed at a high speed of 1200r / min for 20min; 10 parts of water-based resin, 46 Parts of solvent (according to mass ratio: 50 parts of ethanol, 20 parts of isobutanol, 27 parts of deionized water, 3 parts of propylene glycol methyl ether), 0.8 parts of water-based drier JUST-2500, and continue to stir for 20 minutes to prepare a water-based spray paint. Put the spray paint and DME in a weight ratio of 1.2:1 into an aerosol can equipped with a valve and a press head to obtain a water-based spray paint.

Embodiment 3

[0025] Embodiment 3: preparation of black spray paint

[0026] 36 parts of water-based alkyd resin BCW981, 0.8 parts of water-based wetting and dispersing agent, 4 parts of gluconic acid and 10 parts of black material 3-(N-ethyl-isoamylamino)-6-methyl-7-anilinofluoran Put it into the reactor, disperse evenly under the rotating speed of 600r / min, then add 15 parts of nerolithin, and disperse at a high speed for 20min under the rotating speed of 1200r / min; drop 14 parts of water-based resins and 48 parts of solvent in the formula under the rotating speed of 700r / min ( According to the mass ratio: 50 parts of ethanol, 20 parts of sec-butanol, 27 parts of deionized water, 3 parts of propylene glycol methyl ether), 0.6 parts of water-based drier SC-1, and continue to stir for 20 minutes to prepare a water-based spray paint. The spray paint and DME are potted into an aerosol can equipped with a valve and a press head at a weight ratio of 1.2:1 to obtain a water-based spray paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com