Hollow heat gathering glass

A glass and heat-gathering technology, applied in parallel glass structures, climate change adaptation, windows/doors, etc., can solve problems such as difficulty in utilizing solar energy resources, instability, and low energy flow density, so as to improve solar energy utilization efficiency and better gather Thermal insulation effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

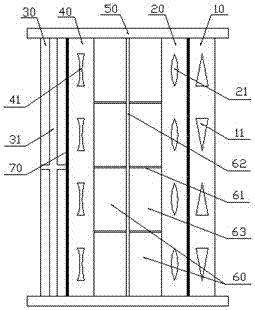

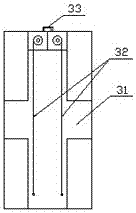

[0020] Such as figure 1 and figure 2 Shown is a structural schematic diagram of a heat-gathering insulating glass described in the present invention.

[0021] The heat-gathering insulating glass of the present invention comprises two pieces of a first layer of glass and a second layer of glass which are spaced apart from each other. The first layer of glass and the second layer of glass are provided with sealing fixtures 50 around them, and are sealed and fixed. The part 50 forms a sealed cavity 60 between the first layer of glass and the second layer of glass; the first layer of glass includes the first tempered glass 10 and the first heat-gathering glass 20, and the first tempered glass 10 and the first An explosion-proof film 70 is arranged between the heat-gathering glass 20, and the second layer of glass includes a second tempered glass 30 and a second heat-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com