Catalyst for ammonia synthesis

A catalyst and a technology for synthesizing ammonia, which is applied in the field of highly active ammonia synthesis catalysts and can solve the problems of high activity of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

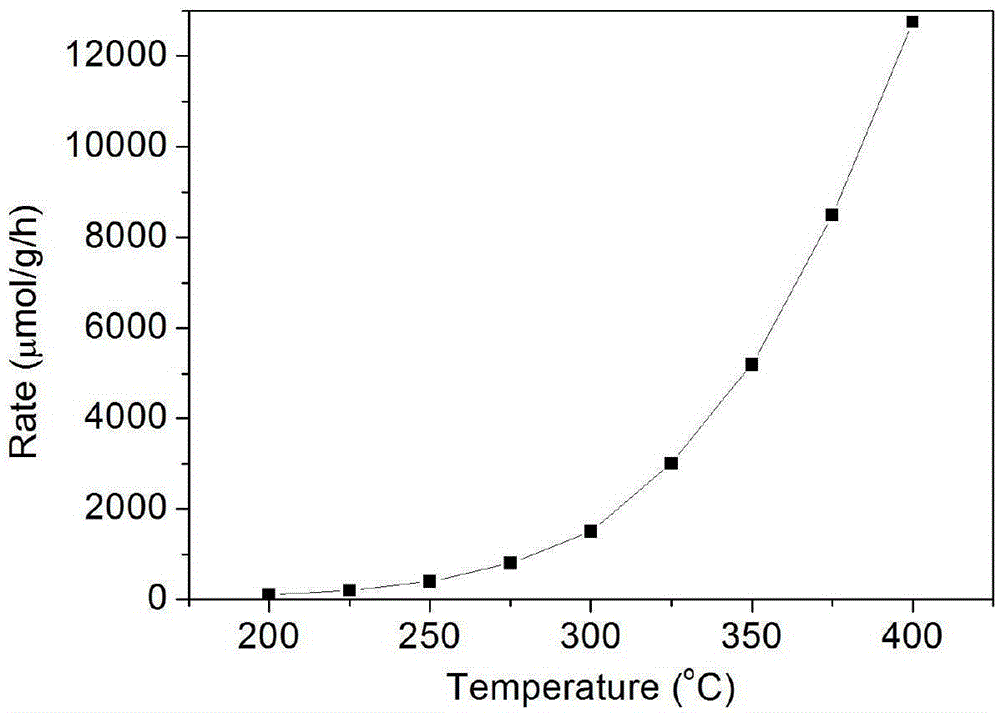

Embodiment 1

[0027] 1gFe 2 After N and LiH were mixed according to the molar ratio of 1:2, they were ball-milled with a planetary ball mill for 24 minutes, and 0.5 g of the sample was placed in a quartz tube reactor, and then 2 Rise to 300°C at 5K / min under the atmosphere, and pre-activate under this condition for 3 days, then cool down to 200°C, switch to syngas, (N 2 and H 2 Mixed gas with a molar ratio of 1:3), the GHSV of the mixed gas is 10000ml / h / g, the pressure of the mixed gas is increased to 10bar, and the temperature rise test is started from 200°C, the results are as follows figure 1 shown.

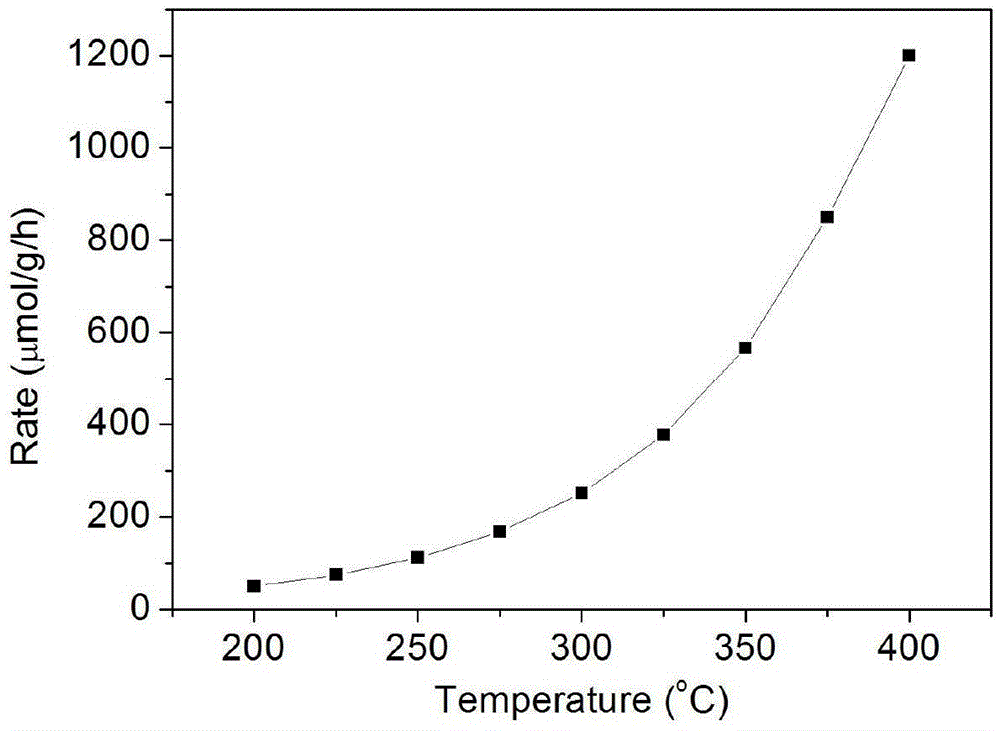

Embodiment 2

[0029] Repeat Example 1, just replace LiH with LiNH of equimolar amount 2 , the activity results as figure 2 shown.

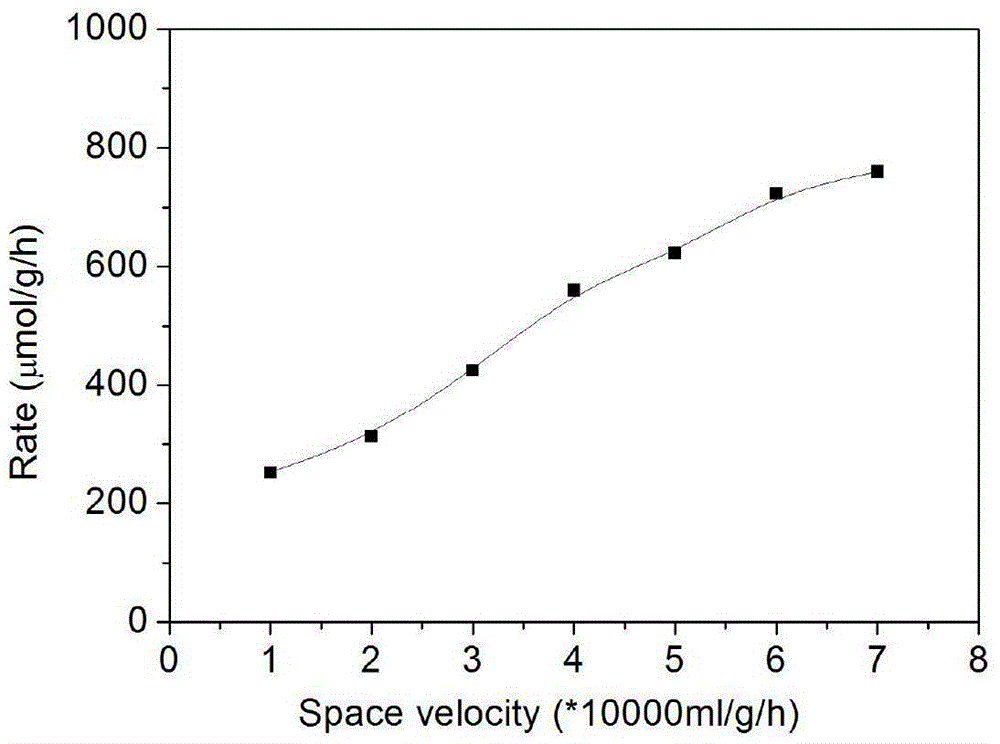

Embodiment 3

[0031] According to the method in Example 1, after the same catalyst is preactivated, H 2 , N 2 Mixed gas, keep the temperature constant at 300°C, change the space velocity of the reaction gas, and test the relationship between the speed of the catalyst to synthesize ammonia and the space velocity, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com