Catalyst system for ethylene selective oligomerization, preparation method and ethylene oligomerization reaction method

A catalyst and selectivity technology, applied in the field of catalysis, can solve the problems of large amount of activator, low total selectivity of 1-hexene and 1-octene, etc., and achieve the effects of long catalyst life, low cost and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] In one embodiment of the present invention, the preparation method of catalyst system comprises the following steps:

[0109] Components a, b, and c are pre-mixed or directly added to the reaction system for in-situ synthesis. That is to say, the catalyst is prepared by pre-mixing ligand a, transition metal compound b, and activator c connected by a linking group containing heteroatoms; it is also possible to mix the ligands connected by chain groups containing heteroatoms a, the transition metal compound b, and the activator c are directly added to the reaction system for in-situ synthesis;

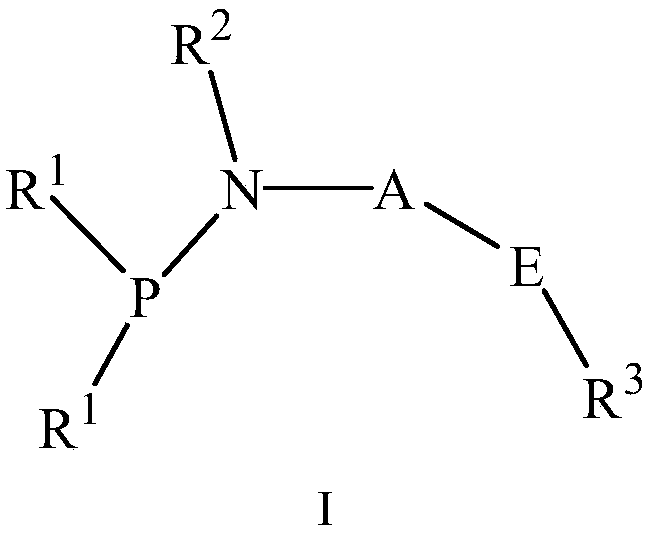

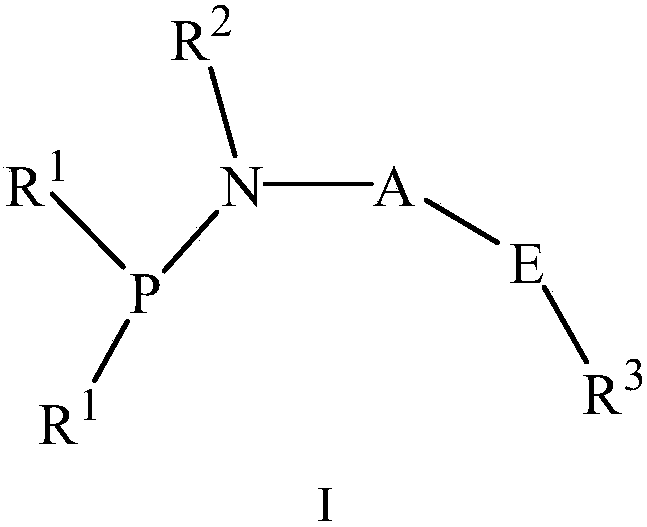

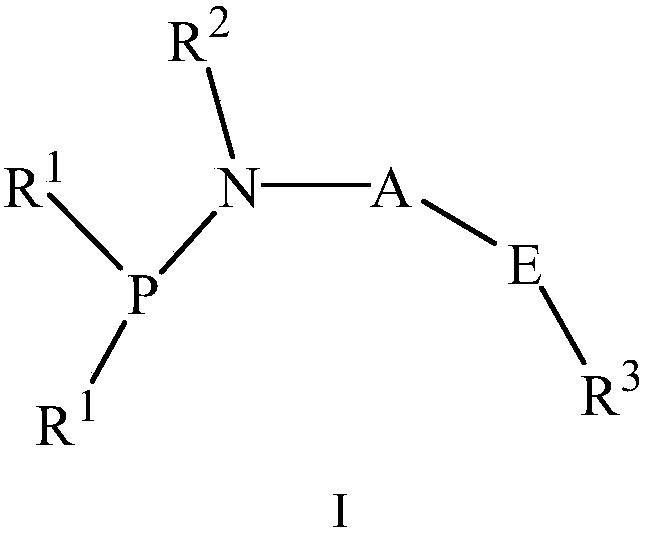

[0110] The reaction mode of ligand a, transition metal compound b and activator c connected by a linking group containing heteroatoms in general formula I can be reacted by liquid phase, such as reacting under the action of a solvent, and the optional solvent Such as toluene, benzene and its derivatives, etc.; also through solid-state reaction; or through in-situ reaction in the ...

Embodiment 1

[0119] 1. Preparation of ligands:

[0120] When A is -CH 2 (CH 3 ) 2 SiCH 2 -, E is a sulfur atom, R 1 Is isopropyl, R 2 is phenyl, R 3 is cyclopentyl, and the ligand is N-((cyclopentylmercaptomethyl)dimethylsilyl)-1,1-diisopropyl-N-phenylphosphineamine (C 21 h 38 NPSSi)

[0121] (1) Preparation of Lithium Anilide

[0122] in the N 2 Add dehydrated THF (200ml) and aniline (9.31g, 0.1mol) into a fully replaced stirred 500ml reactor, stir well and cool to -78°C with liquid nitrogen. Use a 100ml syringe to extract n-butyllithium hexane solution (41.6ml, 2.4mol / L), slowly add it dropwise to the above solution while stirring, keep stirring at -78°C for 1h, then rise to room temperature and continue stirring for 1 hour, then vacuum pump The solvent was removed, n-hexane (100ml) was added, stirred and dispersed, and then filtered. The obtained filtrate was vacuum-extracted at room temperature to obtain 9.97g (0.098mol, 97.8%) of the product.

[0123] (2) prepare 1,1-diiso...

Embodiment 2

[0139] With embodiment 1. The difference is that R 2 For 2,6-diisopropylphenyl. 135.7 g of oligomerization product was obtained, and the catalyst activity was 8.22×10 6 g oligomer / mol Cr·h. The distribution of the oligomerization products is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com