Preparation method of high aluminum zinc-aluminum pseudo-alloy rod materials and wire materials

A pseudo-alloy, high-aluminum-zinc technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problem of difficult forming of high-aluminum-zinc-aluminum alloy wire, achieve high Al content, reduce cost, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0031] step one:

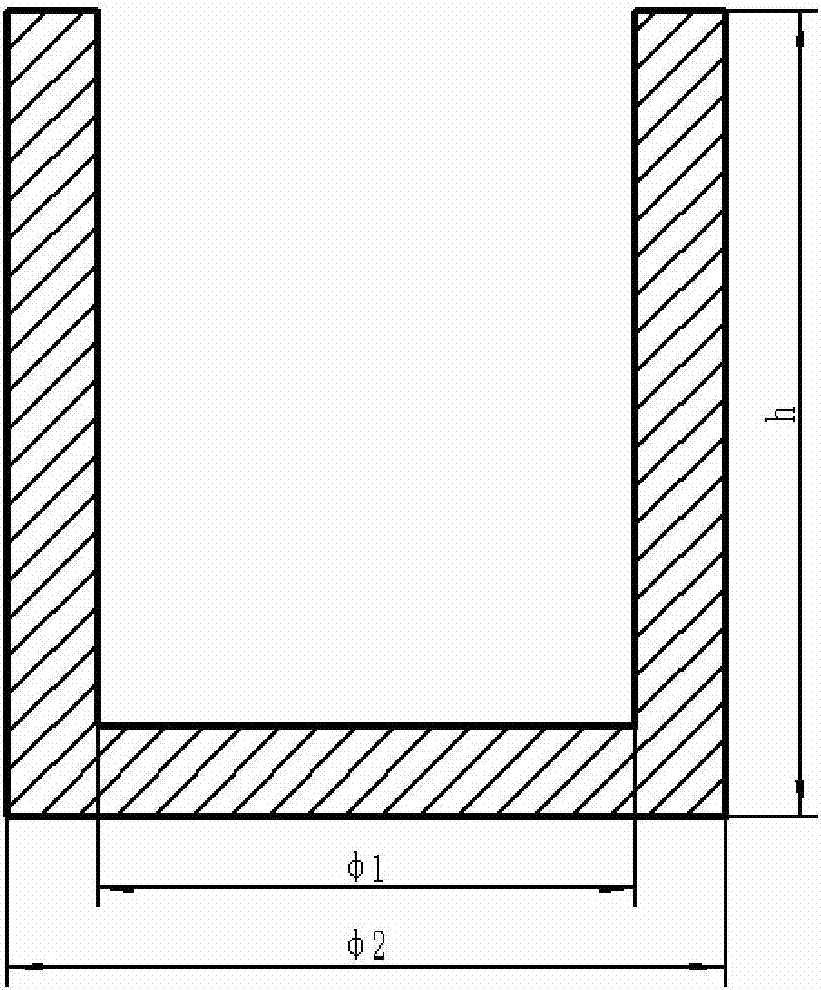

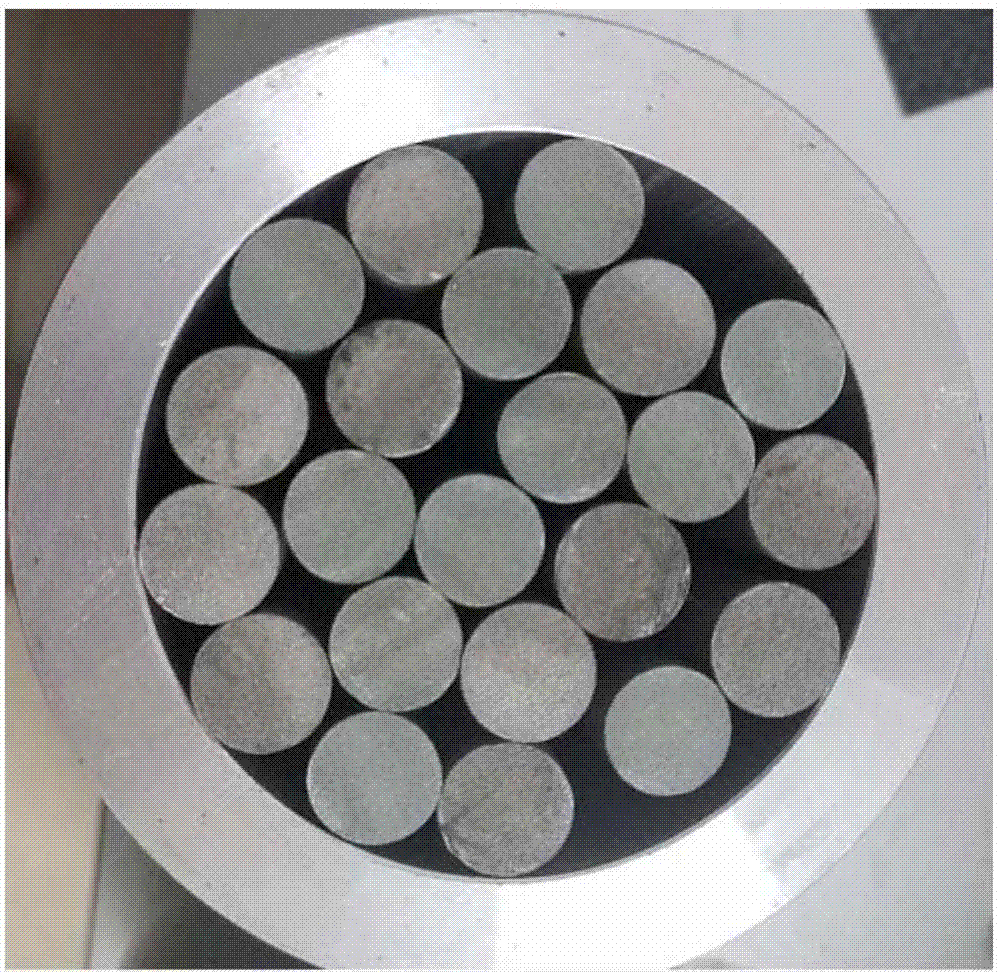

[0032] The cup-shaped 1050A aluminum casing is prepared, and the cross-sectional schematic diagram of the cup-shaped casing is as follows figure 1 As shown in the figure, the production process is as follows: cut a 1050A aluminum tube with a wall thickness of 10mm and a diameter of 80mm into an aluminum tube with a length of 50mm, and the cutting end face is polished or turned smooth; piece. The two are welded together using TIG welding figure 2 Cup sleeve shown in .

[0033] The sheath can also be made of other Al alloys with good corrosion resistance and good deformation ability, and self-designed aluminum alloys added with the components described in the wire. The size of the envelope can also be: diameter: 78-82 mm, thickness: 10-30 mm, and height 50-200 mm.

[0034] Step 2:

[0035] Straighten and cut 1050A or other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com