Preparation method of microbead ceramic surgical knife

A scalpel and ceramic technology, applied in the field of material science and engineering, can solve the problems of negative charge, poor biocompatibility, easy scarring repair, unfavorable wound healing, etc. Short healing time and good histocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

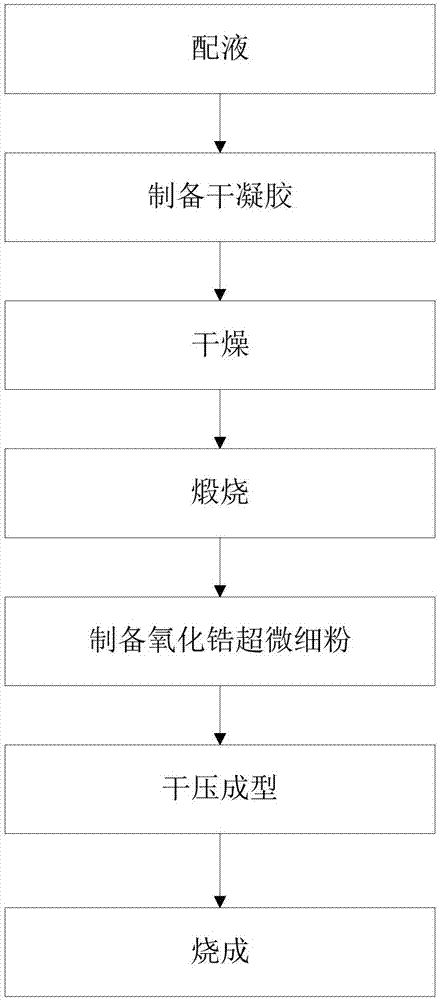

[0035] Such as figure 1 Shown, a kind of preparation method of microbead ceramic scalpel, comprises the following steps:

[0036] (1), dosing

[0037] Take 1 mass part of zircon and place it in a container, then add 2.5 mass parts of absolute ethanol and 4.6 mass parts of distilled water to the container, then add 0.02 mass parts of yttrium oxide to the container, and stir to obtain a mixed solution ;

[0038] (2) Preparation of xerogel

[0039] Heat the mixed solution obtained in step (1) to 70°C, keep the temperature stable, then add 0.45 parts by mass of ammonia water dropwise to the mixed solution, and keep the mixed solution at 70°C after the white translucent sol is formed until a dry Stop heating after gelling;

[0040] (3) dry

[0041] Washing the xerogel obtained in step (2) with distilled water and absolute alcohol successively, and then drying at 80° C. for 38 hours under vacuum conditions to obtain the dried xerogel;

[0042] (4) Calcination

[0043] Calcini...

specific Embodiment 2

[0059] A preparation method of microbead ceramic scalpel, comprising the following steps:

[0060] (1), dosing

[0061] Take 1 mass part of zircon and place it in a container, then add 3 mass parts of absolute ethanol and 5 mass parts of distilled water to the container, then add 0.045 mass parts of yttrium oxide to the container, and stir to obtain a mixed solution ;

[0062] (2) Preparation of xerogel

[0063] Heat the mixed solution obtained in step (1) to 80°C, keep the temperature stable, then add 0.53 parts by mass of ammonia water dropwise to the mixed solution, and keep the mixed solution at 80°C after the white translucent sol is formed until a dry Stop heating after gelling;

[0064] (3) dry

[0065] Washing the xerogel obtained in step (2) with distilled water and absolute alcohol successively, and then drying at 85° C. for 36 hours under vacuum conditions to obtain the dried xerogel;

[0066] (4) Calcination

[0067] Calcining the dried xerogel obtained in st...

specific Embodiment 3

[0079] A preparation method of microbead ceramic scalpel, comprising the following steps:

[0080] (1), dosing

[0081] Take 1 mass part of zircon and place it in a container, then add 2.8 mass parts of absolute ethanol and 4.8 mass parts of distilled water to the container, then add 0.03 mass parts of yttrium oxide to the container, and stir to obtain a mixed solution ;

[0082] (2) Preparation of xerogel

[0083] Heat the mixed solution obtained in step (1) to 75°C, keep the temperature stable, then add 0.5 parts by mass of ammonia water dropwise to the mixed solution, and keep the mixed solution at 75°C after the white translucent sol is formed until a dry Stop heating after gelling;

[0084] (3) dry

[0085] The xerogel obtained in step (2) was washed with distilled water and absolute alcohol in sequence, and then dried under vacuum at 82°C for 37 hours to obtain the dried xerogel;

[0086] (4) Calcination

[0087] Calcining the dried xerogel obtained in step (3) at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com