Diamond-film electrothermal scalpel and temperature control method thereof

A diamond film and scalpel technology, applied in the field of medical devices, can solve the problems of large blade thickness, poor thermal conductivity, affecting the accuracy of blade temperature control, etc., and achieve the effects of improved temperature control accuracy, uniform temperature change, and excellent thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

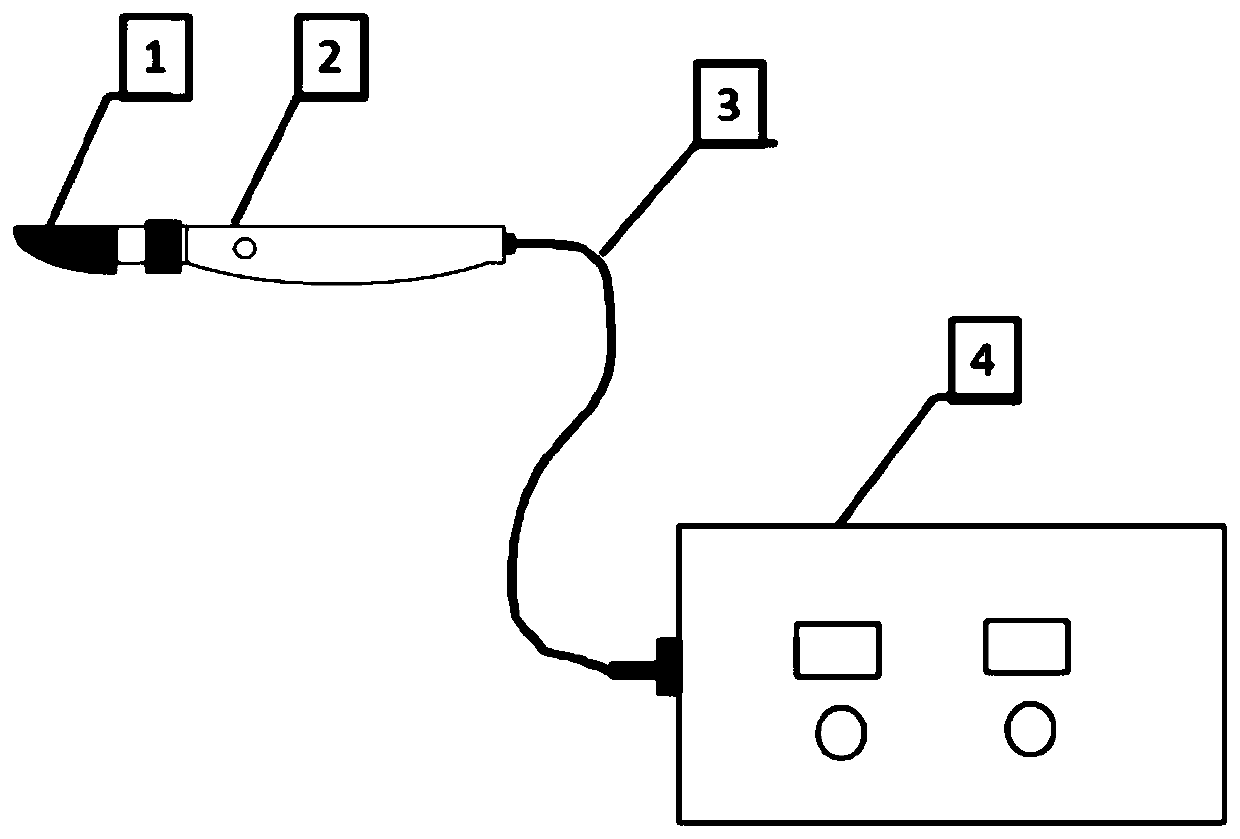

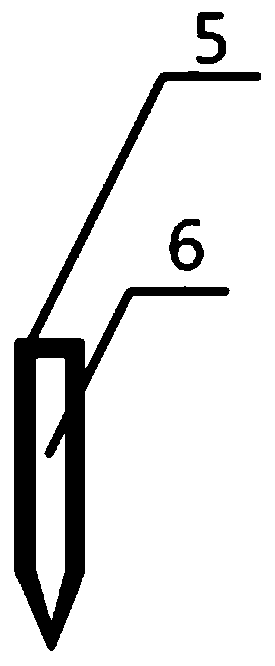

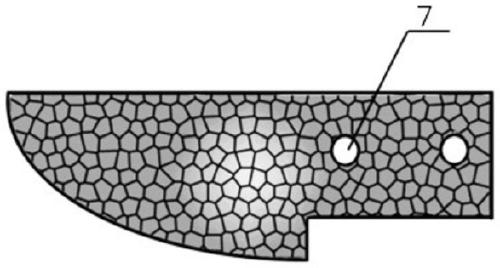

[0030] Such as Figure 1-9 As shown, the reference signs are: blade 1, knife handle 2, control line 3, control device 4, blade base material 5, diamond film layer 6, hole 7, guide groove 8, bump 9, electrothermal converter 10, thermal Sensitive resistance 11, fixed element 12 and button 13.

[0031] A diamond film electrothermal scalpel comprises a blade 1, a knife handle 2, a control line 3 and a control device 4 connected in sequence. Wherein, the blade 1 includes a blade substrate 5 and a diamond thin film layer 6, and the surface of the blade substrate 5 is modified with the diamond thin film layer 6 by physical vapor deposition or chemical vapor deposition.

[0032] The head of the knife handle 2 has a guide groove 8 for blade installation and a projection 9 matching the mounting hole at the tail of the blade 1 for installati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com