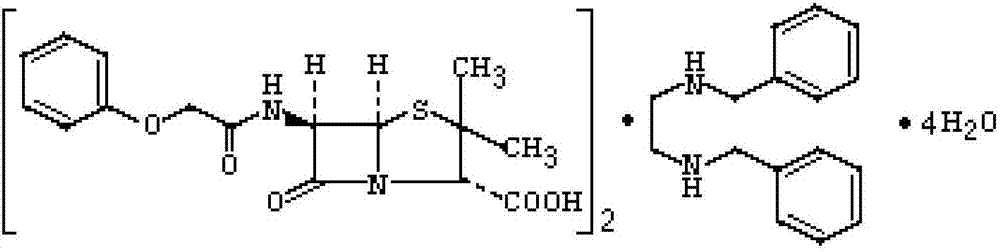

Preparation method of benzathine benzylpenicillin V

A technology of benzathine penicillin and penicillin V, which is applied in the field of compound preparation, can solve the problems of unsatisfactory industrial production and clean production, failure to achieve good results, poor product quality and yield, etc., so as to facilitate practical operation and control , Controllable crystal growth rate, reduce the difficulty of separation and washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of benzathine penicillin V of the present invention, concrete implementation steps are as follows:

[0043] (a) Preparation of reaction solution

[0044] At room temperature, add penicillin V salt into an organic solvent with a concentration range of 50-95%, and prepare a solution A with a mass volume ratio of 1:5-15;

[0045] Add N,N'-dibenzylethylenediaminediacetic acid into an organic solvent with a concentration range of 50-95%, and prepare a B solution with a mass-volume ratio of 1:5-15;

[0046] Water by volume: the amount of organic solvent (50~95%)=1:0.5~10 is configured into reaction solvent C; The volume of reaction solvent C is 0.5~20 times of total volume of A solution and B solution;

[0047] When the ratio of the amount of penicillin V salt to N,N'-dibenzylethylenediaminediacetic acid is about 2:1, the reaction can be more complete, and the double-flow operation is more convenient when the volumes of solution A and solution B are th...

Embodiment 1

[0055] (a) Preparation of reaction solution: at room temperature, add 10kg of penicillin V sodium crude drug into 50L of 50% ethanol solution to make penicillin V potassium ethanol solution, i.e. A solution; Benzyl ethylenediamine diacetic acid is added to 50L of ethanol solution with a concentration of 50% to make N, N'-dibenzyl ethylenediamine diacetic acid ethanol solution, i.e. solution B; by volume ratio water: ethanol solution (50% )=1:0.5 amount configuration 500L reaction solvent C;

[0056] (b) Pre-reaction: Take 2% of the respective total amounts of the A solution and the B solution and add it to the reaction solvent C at the same time, stir at a speed of 100 rpm until the crystals appear, and then grow the crystals for 10 minutes;

[0057] (c) Final reaction: After the crystal growth is completed, the remaining A solution and B solution are simultaneously added to the reaction solvent C after the pre-reaction within 1 hour, and then fully reacted for 1 hour at the s...

Embodiment 2

[0060] (a) Preparation of reaction solution: at room temperature, add 12kg of penicillin V potassium crude drug into 60L of 80% methanol solution to make penicillin V potassium methanol solution, namely A solution; Benzyl ethylenediamine diacetic acid is added into 50L of 70% ethanol solution to make N, N'-dibenzyl ethylenediamine diacetic acid ethanol solution, i.e. solution B; by volume ratio water: ethanol solution (concentration 60 %)=1:4 amount configuration 550L reaction solvent C;

[0061] (b) Pre-reaction: Take 2% of the respective total amounts of the A solution and the B solution and add it to the reaction solvent C at the same time, stir at a speed of 100 rpm until the crystals appear, and then grow the crystals for 10 minutes;

[0062] (c) Final reaction: After the crystal growth is completed, the remaining A solution and B solution are simultaneously added to the reaction solvent C after the pre-reaction within 1 hour, and then fully reacted for 1 hour at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com