Greenhouse film and preparation method thereof

A greenhouse film and ethylene technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, agricultural machinery and implements, etc., can solve the problems of shortening the service life of the greenhouse film, the film is difficult to withstand, and the film is easily broken, and achieves good toughness. , reduce degradation, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

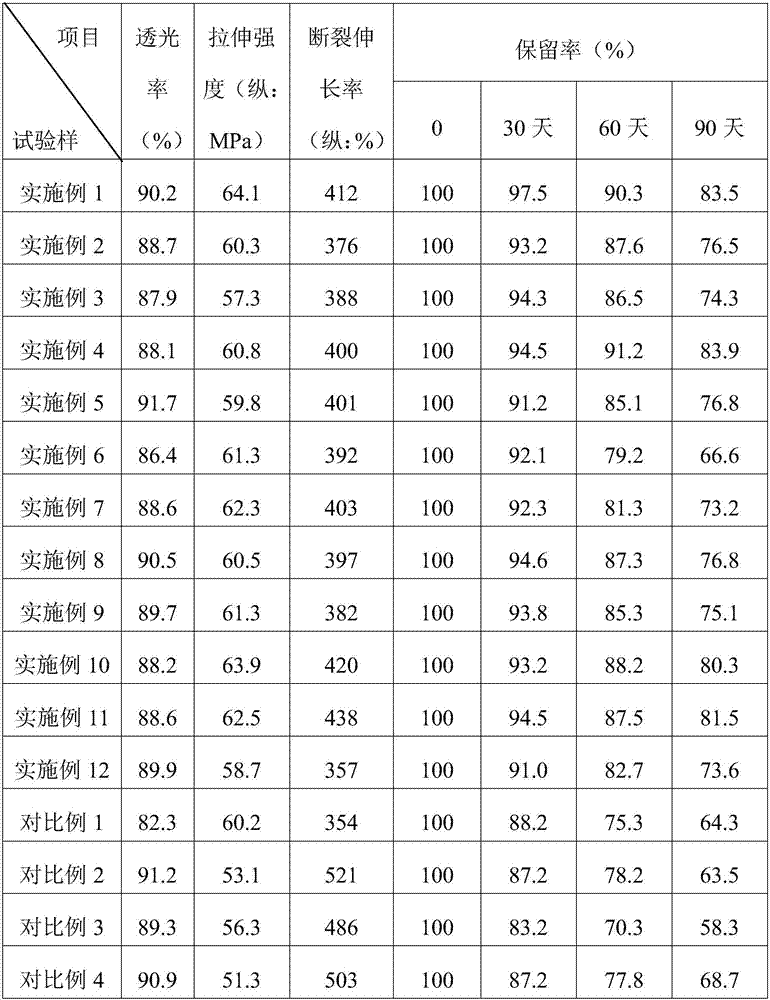

Examples

Embodiment 1

[0034] A greenhouse film prepared by the following process:

[0035] S1: Weigh 100 parts of LDPE, 50 parts of LLDPE, 20 parts of P1, 0.2 parts of talcum powder, 4 parts of superfine shell powder, 0.2 parts of 2,2'-thiobis(p-tert-octylphenol)nickel-n-butylamine The complex compound is uniformly mixed and then extruded and granulated to prepare the outer layer masterbatch for subsequent use;

[0036] S2: Weigh 100 parts of LDPE, 15 parts of LLDPE, 10 parts of P2, 0.4 parts of talcum powder, 8 parts of superfine shell powder, 0.05 parts of 2,2'-thiobis(p-tert-octylphenol)nickel-n-butylamine The complex compound is uniformly mixed and then extruded and granulated to prepare the middle layer masterbatch for subsequent use;

[0037] S3: Weigh 100 parts of LDPE, 30 parts of LLDPE, 20 parts of ethylene-vinyl acetate copolymer, 0.2 parts of talcum powder, 4 parts of ultrafine shell powder, and 0.02 parts of 2,2'-thiobis(p-tert-octylphenol) nickel -N-butylamine complex, 2 parts of bis...

Embodiment 2

[0041] A greenhouse film prepared by the following process:

[0042] S1: Weigh 100 parts of LDPE, 40 parts of LLDPE, 15 parts of P1, 0.2 parts of talcum powder, 2 parts of superfine shell powder, 0.5 parts of 2,2'-thiobis(p-tert-octylphenol)nickel-n-butylamine The complex compound is uniformly mixed and then extruded and granulated to prepare the outer layer masterbatch for subsequent use;

[0043] S2: Weigh 100 parts of LDPE, 25 parts of LLDPE, 12 parts of P2, 0.4 parts of talcum powder, 6 parts of superfine shell powder, 0.01 part of 2,2'-thiobis(p-tert-octylphenol)nickel-n-butylamine The complex compound is uniformly mixed and then extruded and granulated to prepare the middle layer masterbatch for subsequent use;

[0044] S3: Weigh 100 parts of LDPE, 15 parts of LLDPE, 25 parts of ethylene-vinyl acetate copolymer, 0.4 parts of talcum powder, 2 parts of ultrafine shell powder, 0.02 parts of 2,2'-thiobis(p-tert-octylphenol) nickel -n-butylamine complex, 0.8 part of bis(2,2...

Embodiment 3

[0048] A greenhouse film prepared by the following process:

[0049] S1: Weigh 100 parts of LDPE, 60 parts of LLDPE, 25 parts of P1, 0.4 parts of talc powder, 5 parts of superfine shell powder, 0.5 parts of titanium dioxide, 0.1 part of 2,2'-thiobis(p-tert-octylphenol) nickel -n-butylamine complex compound, extrude and granulate after mixing evenly, and prepare the outer layer masterbatch for subsequent use;

[0050] S2: Weigh 100 parts of LDPE, 30 parts of LLDPE, 15 parts of P2, 0.2 parts of talcum powder, 10 parts of superfine shell powder, 0.05 parts of titanium dioxide, 0.1 part of 2,2'-thiobis(p-tert-octylphenol) nickel -n-butylamine complex compound, extrude and granulate after mixing evenly, and prepare the middle layer masterbatch for subsequent use;

[0051] S3: Weigh 100 parts of LDPE, 20 parts of LLDPE, 15 parts of ethylene-vinyl acetate copolymer, 0.2 parts of talcum powder, 5 parts of superfine shell powder, and 0.01 part of 2,2'-thiobis(p-tert-octylphenol) nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com