Blue membrane composition, uncured glue, blue basal membrane, preparation method therefor and application of blue basal membrane

A composition and uncured technology, which is applied in the field of cameras, can solve the problems of expensive blue glass substrates and large thickness, and achieve the effects of avoiding aberrations, low manufacturing costs, and easy material acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

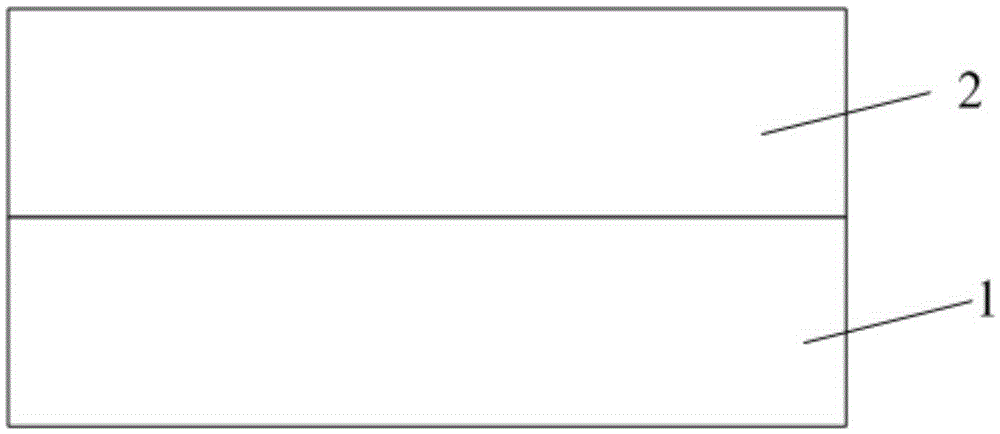

[0067] In another embodiment of the present application, a method for preparing the above-mentioned blue base film is provided, the above-mentioned preparation method includes: coating the above-mentioned blue film composition on the surface of the substrate; and applying the above-mentioned blue film composition Cured into a film.

[0068] The blue base film prepared by the above preparation method plays the same role as the blue glass substrate, and at the same time, it avoids the phenomenon that only the expensive blue glass substrate produced in Japan can be used in the filter, and it is prepared from The thin film is light in weight and small in volume, which is convenient for cutting.

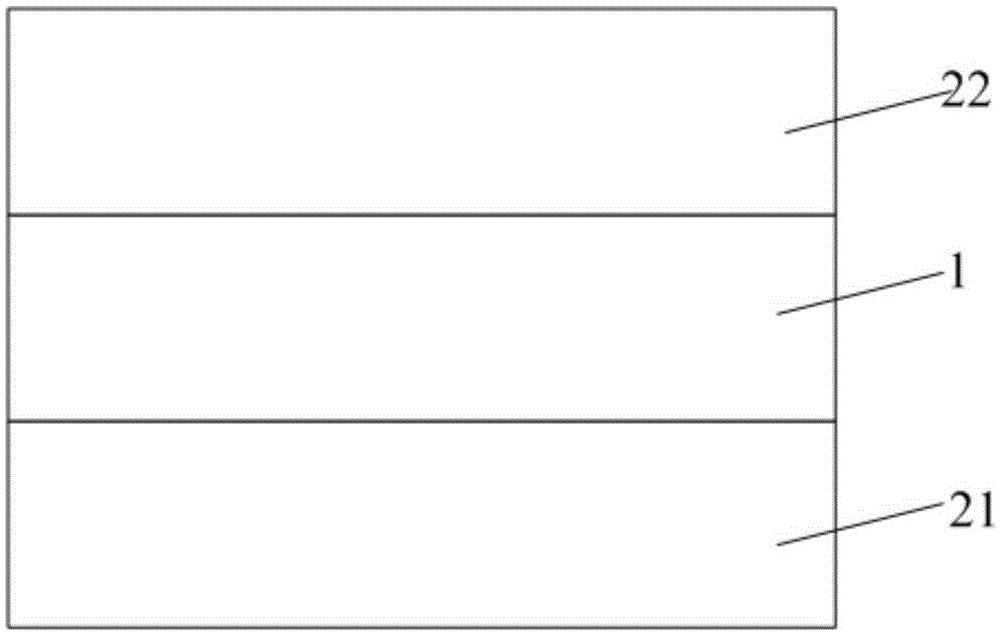

[0069] In yet another embodiment of the present application, a filter is provided, and the filter includes a blue base film, and the blue base film is the above-mentioned blue base film.

[0070] In this filter, the above-mentioned blue base film is used to replace the blue glass produce...

Embodiment 1

[0082] The blue film composition comprises resin main body, blue dyestuff and solvent, and wherein, resin main body is cyclic olefin resin " ZEONOR1420R " (Japanese zeon Co., Ltd. manufacture); Blue dyestuff is cobalt blue, and the weight of cobalt blue is resin main body 2% by weight; the solvent is cyclohexane, and the viscosity of the mixture of the resin body and the solvent is 2500Cps.

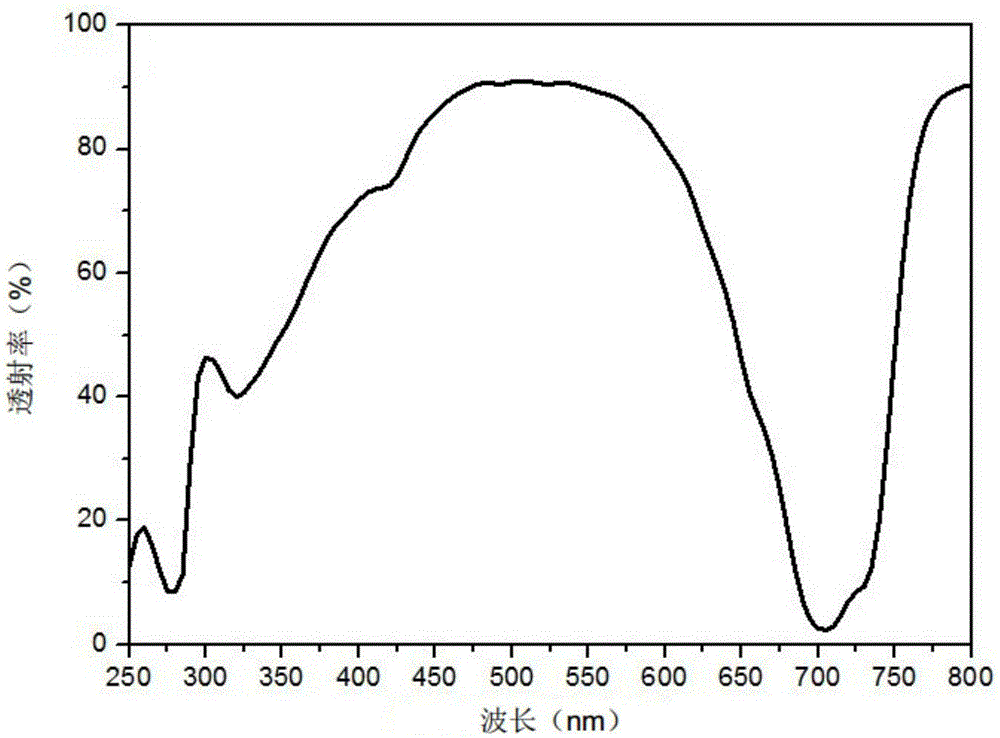

[0083] The above-mentioned blue film composition is cured by photo-curing to form a blue film (blue base film), the thickness of the blue film is 200 μm, and the refractive index is 1.45.

Embodiment 2

[0085] The blue film composition includes a resin body, a blue dye, a solvent and nano functional particles, wherein the resin body is a cyclic olefin resin "APEL#6015" (manufactured by Mitsui Chemicals Co., Ltd.); the blue dye is copper phthalocyanine, The weight of copper phthalocyanine accounts for 0.01% of the weight of the resin main body; the solvent is carbon tetrachloride, and the viscosity of the mixture of the resin main body and the solvent is 1Cps. The nano functional particle is Fe-ZnSe particle, the weight of the particle is 1% of the weight of the resin main body, and the average particle diameter of the particle is 10nm.

[0086] The above-mentioned blue film composition is cured by thermal curing to form a blue film, the thickness of the blue film is 2 μm, and the refractive index is 1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com