Oil-in-water association-type non-crosslinking fracturing fluid concentrating thickener and preparation method thereof and fracturing fluid

An associative, non-cross-linking technology, applied in the field of fracturing fluids, can solve problems affecting the performance of fracturing fluids, insufficient dissolution, uneven mixing, etc., and achieve physical cross-linking network strength increase, obvious dissolution time, The effect of enhancing sand-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing the above-mentioned oil-in-water association type non-crosslinked fracturing fluid concentrated thickener, comprising the following steps:

[0062] A) mixing and stirring the dispersed phase, the dispersion medium and the composite emulsifier to obtain an oil-in-water emulsion;

[0063] B) adding a hydrophobic association polymer fracturing fluid thickener to the oil-in-water emulsion, mixing and stirring to obtain an oil-in-water association type non-crosslinked fracturing fluid concentrated thickener.

[0064] In the present invention, firstly, the dispersed phase, the dispersed medium and the composite emulsifier are mixed and stirred to obtain the oil-in-water emulsion;

[0065] In the present invention, the mixing and stirring temperature is 35-70°C, preferably 40-65°C, more preferably 50-60°C; the mixing and stirring speed is 300-800rmp, preferably 400-700rmp; the mixing The stirring time is 20-60 minutes...

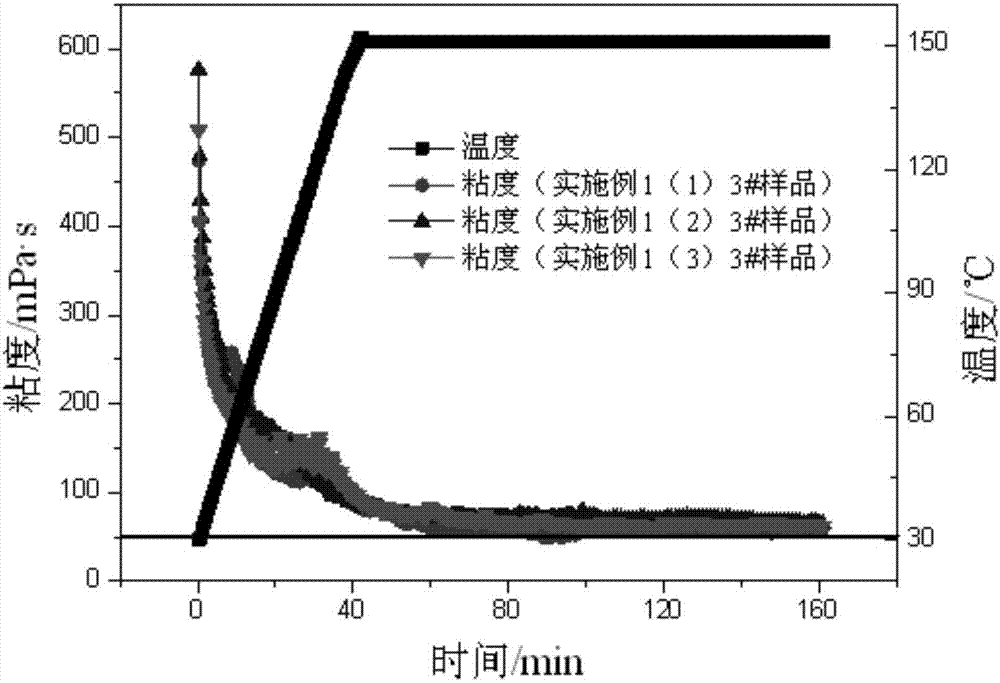

Embodiment 1

[0081] Preparation of oil-in-water (O / W) associative non-crosslinked fracturing fluid concentrated thickener (compound emulsifier is fatty alcohol polyoxyethylene ether AEO-3 + alkyl glycoside APG1214)

[0082] (1) An O / W associative non-crosslinked fracturing fluid concentrated thickener, comprising the following components in mass percentage:

[0083] 0# diesel oil 28.71%, water 43.06%, hydrophobic association polymer fracturing fluid thickener (hereinafter referred to as fracturing fluid thickener) 25%, fatty alcohol polyoxyethylene ether AEO-3 2.87%, alkyl glycoside APG1214 0.36%;

[0084] The fracturing fluid thickener is acrylamide / sodium acrylate / N-dodecyl substituted acrylamide copolymer, and the composite emulsifier is AEO-3 and APG1214 (ratio 8:1), and the preparation steps are as follows :

[0085] At 60°C, control the mass ratio of oil to water to 4:6, mix 287.1g diesel, 430.6g water, 28.7g AEO-3, 3.6g APG1214 to emulsify evenly, stir at 600rmp for 30min to form ...

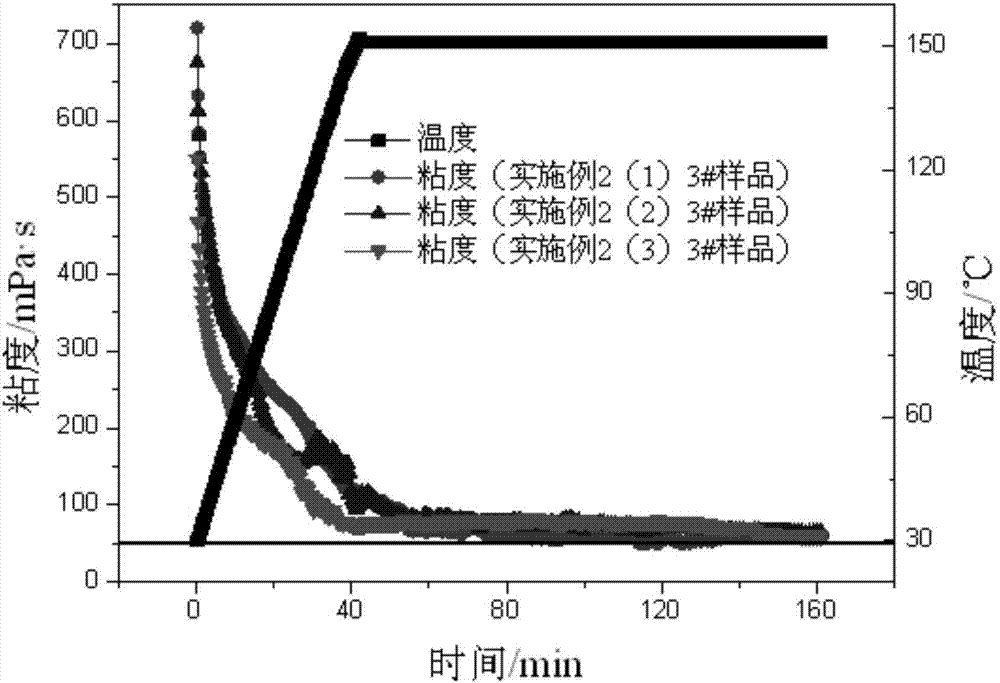

Embodiment 2

[0095] Preparation of oil-in-water (O / W) associative non-crosslinked fracturing fluid concentrated thickener (compound emulsifier is lauryl polyoxyethylene ether LAE-4+polyethylene glycol dioleate PEG600DO)

[0096] (1) An O / W associative non-crosslinked fracturing fluid concentrated thickener, comprising the following components in mass percentage:

[0097] 0# diesel oil 28.71%, water 43.06%, fracturing fluid thickener 25%, lauric acid polyoxyethylene ether LAE-42.87%, polyethylene glycol dioleate PEG600DO 0.36%;

[0098] The fracturing fluid thickener is acrylamide / sodium acrylate / N-vinylpyrrolidone / cetyl acrylate copolymer, and the composite emulsifier is LAE-4 and PEG600DO (ratio 8:1), The preparation steps are as follows:

[0099] At 40°C, control the mass ratio of oil to water to 4:6, mix 287.1g diesel, 430.6g water, 28.7g LAE-4, 3.6g PEG600DO to emulsify evenly, stir at 600rmp for 30min to form a stable oil-in-water emulsion , and finally add 250g of fracturing fluid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com