Mechanical laminated solar cell and preparation method thereof

A solar cell and mechanical technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of unsatisfactory light efficiency of devices, and achieve the effects of improving photoelectric conversion efficiency, simple preparation process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

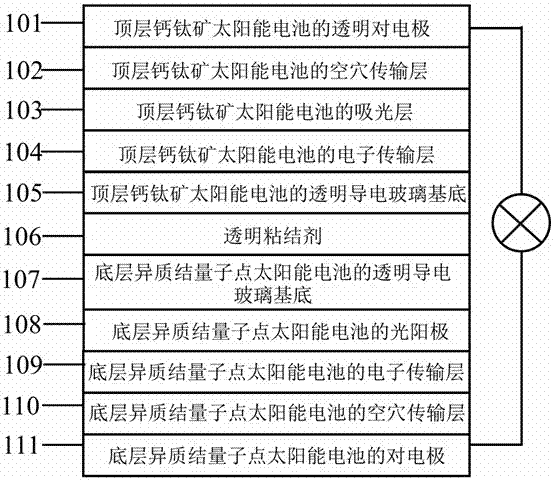

Image

Examples

Embodiment 1

[0042] The mechanical tandem solar cell of the top transparent perovskite solar cell and the bottom heterojunction quantum dot solar cell of this embodiment includes the following steps:

[0043] 1. Preparation method of top-layer transparent perovskite solar cells:

[0044] (1) Select transparent FTO conductive glass and clean it;

[0045] (2) Spin-coat the electron transport layer on the transparent FTO conductive glass;

[0046] (3) Spin-coat the perovskite light-absorbing layer on the electron transport layer;

[0047] (4) Spin-coat the hole transport layer on the perovskite light absorbing layer;

[0048] (5) Deposit a transparent counter electrode on the hole transport layer to obtain a transparent perovskite solar cell;

[0049] In the above preparation method, in the step (1), the FTO transparent conductive glass is washed with deionized water, acetone, and ethanol for 15 minutes respectively, and after drying, it is treated with an ultraviolet ozone cleaning machin...

Embodiment 2

[0066] The mechanical tandem solar cell of the top transparent perovskite solar cell and the bottom heterojunction quantum dot solar cell of this embodiment includes the following steps:

[0067] 1. Preparation method of top-layer transparent perovskite solar cells:

[0068] (1) Select transparent FTO conductive glass and clean it;

[0069] (2) Spin-coat the electron transport layer on the transparent FTO conductive glass;

[0070] (3) Spin-coat the perovskite light-absorbing layer on the electron transport layer;

[0071] (4) Spin-coat the hole transport layer on the perovskite light absorbing layer;

[0072] (5) Deposit a transparent counter electrode on the hole transport layer to obtain a transparent perovskite solar cell;

[0073] In the above preparation method, in the step (1), the FTO transparent conductive glass is washed with deionized water, acetone, and ethanol for 20 min respectively, and after drying, it is treated with an ultraviolet ozone cleaner to remove r...

Embodiment 3

[0090] The mechanical tandem solar cell of the top transparent perovskite solar cell and the bottom heterojunction quantum dot solar cell of this embodiment includes the following steps:

[0091] 1. Preparation method of top-layer transparent perovskite solar cells:

[0092] (1) Select transparent FTO conductive glass and clean it;

[0093] (2) Spin-coat the electron transport layer on the transparent FTO conductive glass;

[0094] (3) Spin-coat the perovskite light-absorbing layer on the electron transport layer;

[0095] (4) Spin-coat the hole transport layer on the perovskite light absorbing layer;

[0096] (5) Deposit a transparent counter electrode on the hole transport layer to obtain a transparent perovskite solar cell;

[0097] In the above preparation method, in the step (1), the FTO transparent conductive glass is washed with deionized water, acetone, and ethanol for 18 minutes respectively, and after drying, it is treated with an ultraviolet ozone cleaner to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com