Preparation method of hydrophilic porous graphite water transport plate and water transport plate thereof

A technology of porous graphite and water transport plates, used in fuel cells, electrochemical generators, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

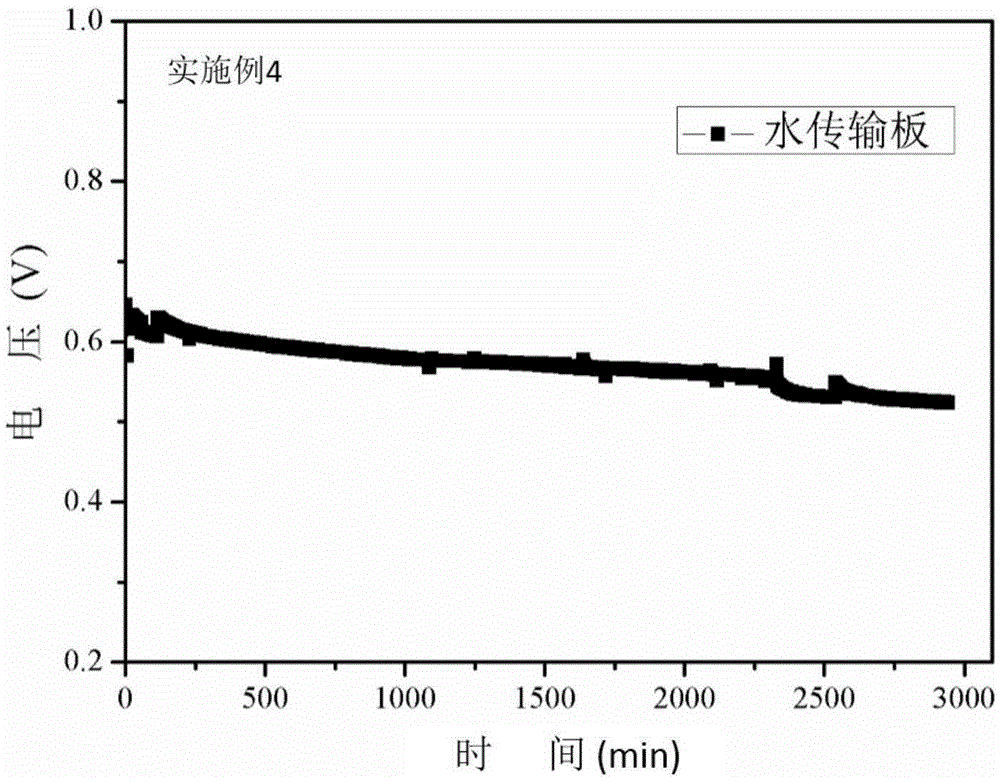

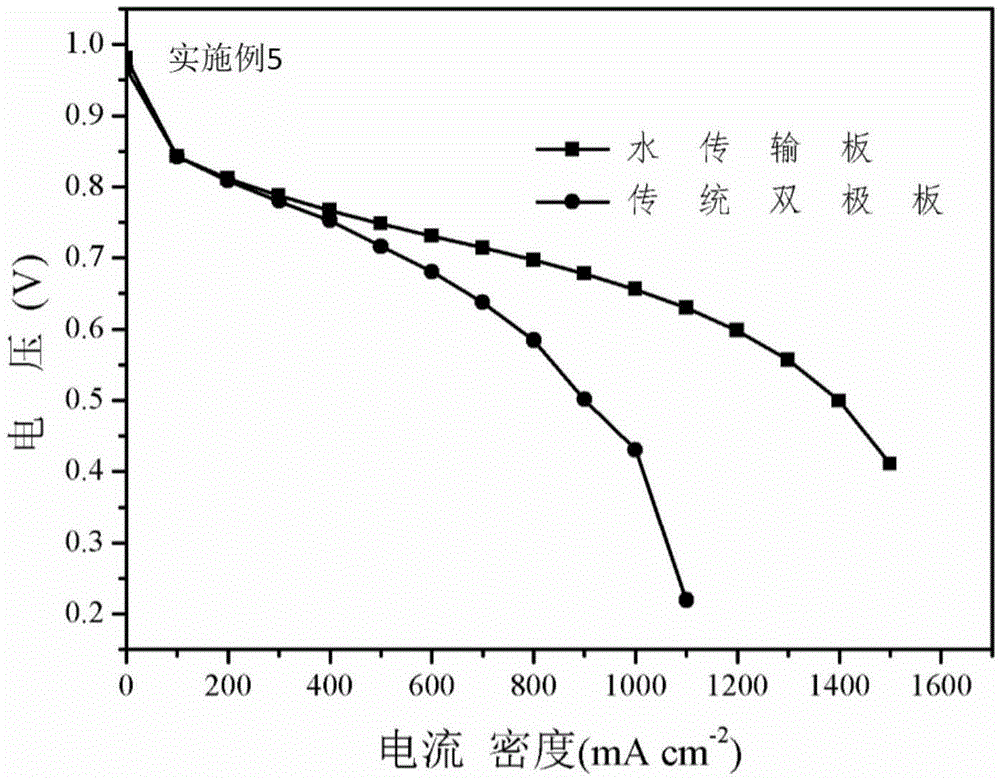

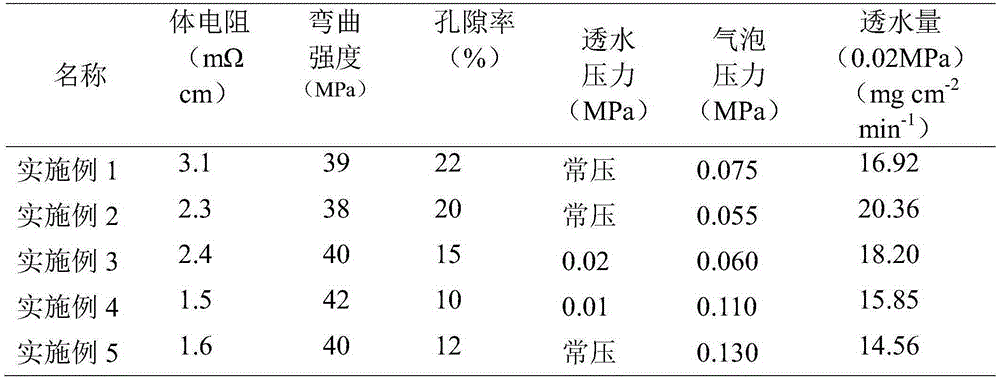

Examples

Embodiment 1

[0020] Example 1: 50ml of sodium nitrate solution (0.1mol / L) and 5g of ethyl orthosilicate were mixed and stirred for 30min. After TEOS is completely dissolved, slowly add hydrochloric acid solution (0.1mol / L) dropwise until the pH value is close to 2, and then stir for 1 hour under the greenhouse to obtain the electrodeposition precursor solution. A porous carbon plate with an average pore diameter of 7 μm is placed in the precursor solution of electro-assisted deposition, the porous carbon plate is used as the working electrode, the dense and smooth graphite plate is used as the reference electrode and the counter electrode, and a constant voltage is applied to the working electrode by the constant voltage method- Electro-assisted deposition was performed at 3.5V for 120s, and the hydrophilized porous carbon plate was calcined at 400°C for 1 hour to obtain a porous hydrophilic graphite water transport plate.

Embodiment 2

[0021] Example 2: 50ml of potassium nitrate solution (0.2mol / L) and 5g of ethyl orthosilicate were mixed and stirred for 30min. After TEOS is completely dissolved, slowly add sulfuric acid solution (0.1mol / L) dropwise until the pH value is close to 3, and then stir for 1 hour under the greenhouse to obtain the electrode-assisted deposition precursor solution. A porous graphite plate with an average pore diameter of 7 μm was placed in the electro-assisted deposition precursor solution (the electro-assisted deposition precursor liquid was submerged in the porous graphite plate), the porous graphite plate was used as the working electrode, and the dense and smooth graphite plate was used as the reference electrode and counter electrode. The constant current method applies a constant current of 200mA cm on the working electrode -2 Electro-assisted deposition was performed for 200s, and the hydrophilized porous graphite plate was calcined at 400° C. for 2 hours at a high temperatur...

Embodiment 3

[0022] Example 3: 100ml of sodium nitrate solution (0.2mol / L) and 5g of butyl titanate were mixed and stirred for 30min. After TEOS is completely dissolved, slowly add hydrochloric acid solution (0.1mol / L) dropwise until the pH value is close to 4, and then stir for 1 hour in the greenhouse to obtain the electrodeposition precursor solution. A porous graphite plate with an average pore diameter of 5 μm was placed in the electro-assisted deposition precursor solution (the electro-assisted deposition precursor liquid was submerged in the porous graphite plate), the porous graphite plate was used as the working electrode, and the dense and smooth graphite plate was used as the reference electrode and counter electrode. The pulse voltage method applies a pulse voltage on the working electrode, the pulse range is (-3)-0V for electro-assisted deposition, the pulse time interval is 1ms, and the number of pulses is 200 times. Calcined for 2 hours, the porous hydrophilic graphite water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com