A manufacturing method of a high-precision carbon fiber ring-focus antenna sub-reflector

A technology of sub-reflector and ring-focus antenna, which is applied in the field of communication, can solve the problems of low honeycomb density of aramid paper, difficulty in molding, complicated molding steps, etc., and achieve the effects of strong accuracy, simplified molding steps, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

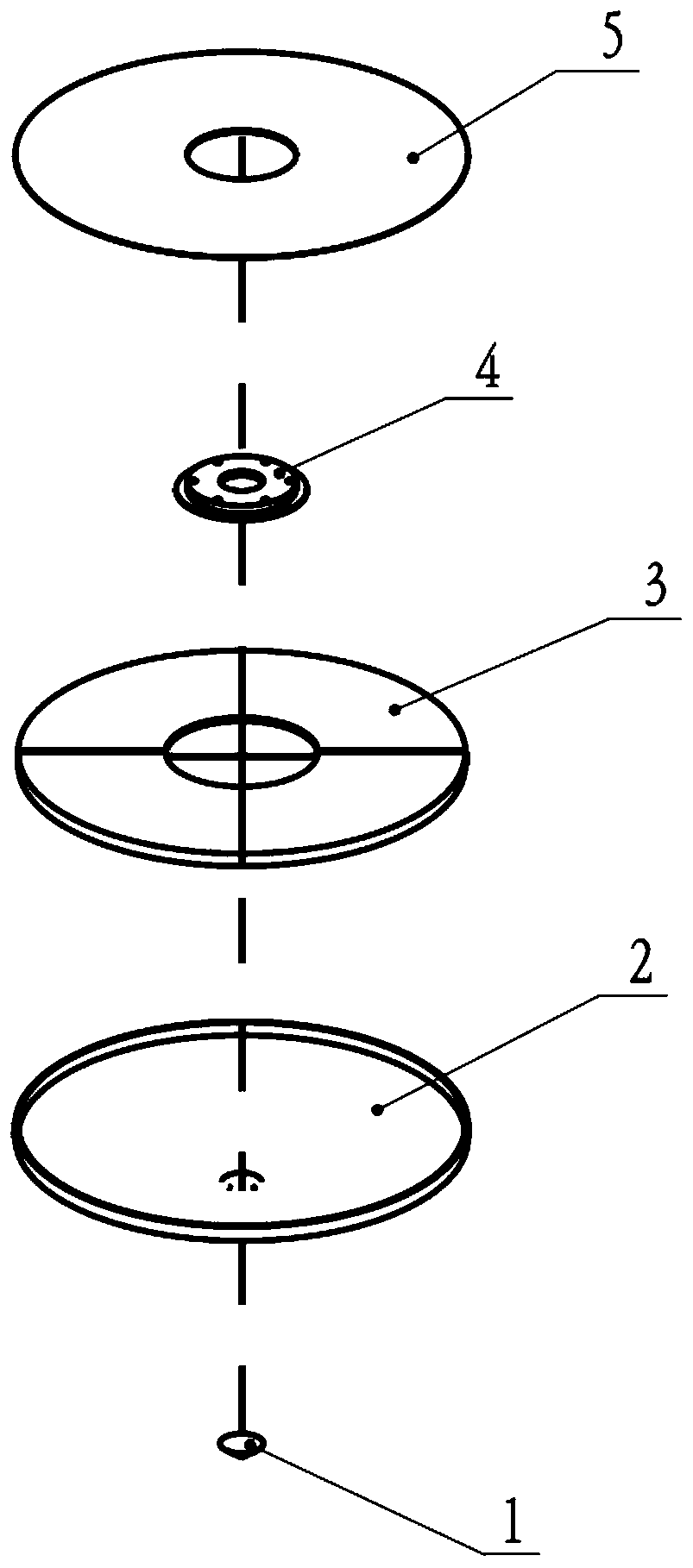

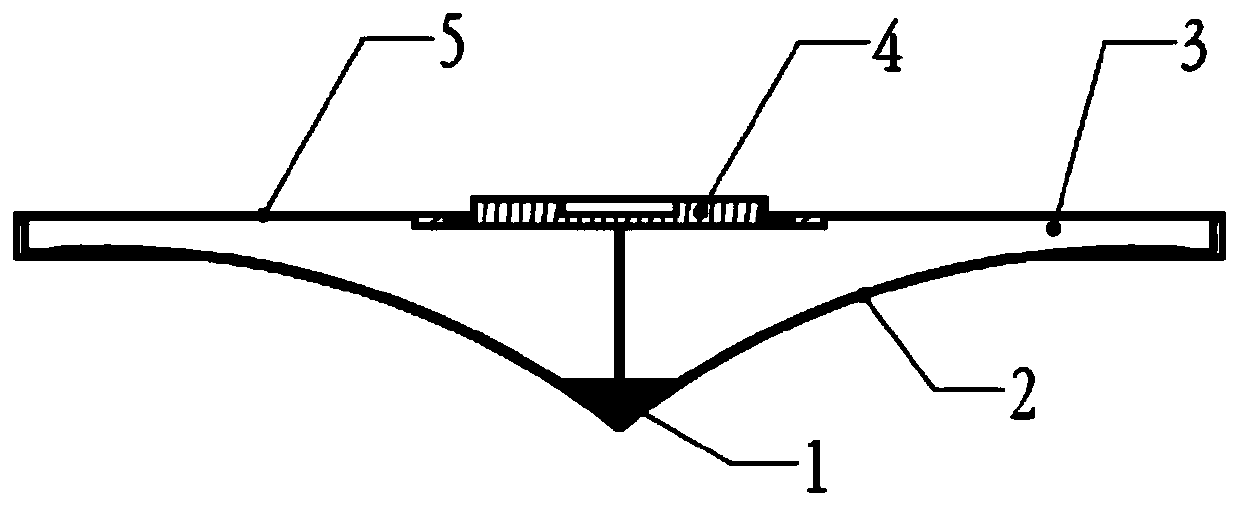

[0036] to combine figure 1 and figure 2 , the present invention will be further described below.

[0037] Provides a high-precision carbon fiber ring-focus antenna sub-reflector, including a convex point 1, an outer skin 2, a sandwich core 3, a metal embedded part 4, and an upper skin 5. The convex point 1 is composed of a metal reflective layer and Multiple layers of circular inner carbon fiber prepregs of decreasing diameter are composited together to form the cone. The outer skin 2 includes a composite metal reflective layer and an outer skin carbon fiber prepreg cladding layer, and a sandwich material 3 is arranged above the convex point in the outer skin, and the sandwich material is foam. The upper skin 5 is covered above the sandwich material 3, the upper skin is a carbon fiber prepreg laying layer, the bottom surface of the sandwich is flat, and the top surface of the convex point can just be butted on the bottom surface of the sandwich to form The outer wall is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com