Preparation method and application of konjac-flour-based porous carbon material

A porous carbon and powder-based technology, which is applied in carbon preparation/purification, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of complex preparation process and high preparation cost of supercapacitor electrode materials, and achieve excellent electrical properties. Effects of chemical properties, high specific surface area, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

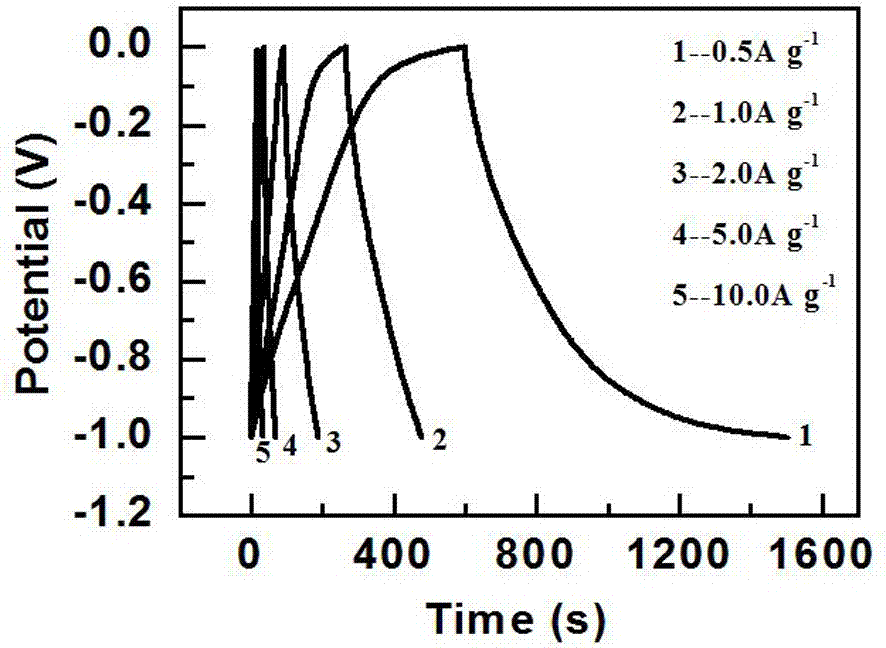

Examples

preparation example Construction

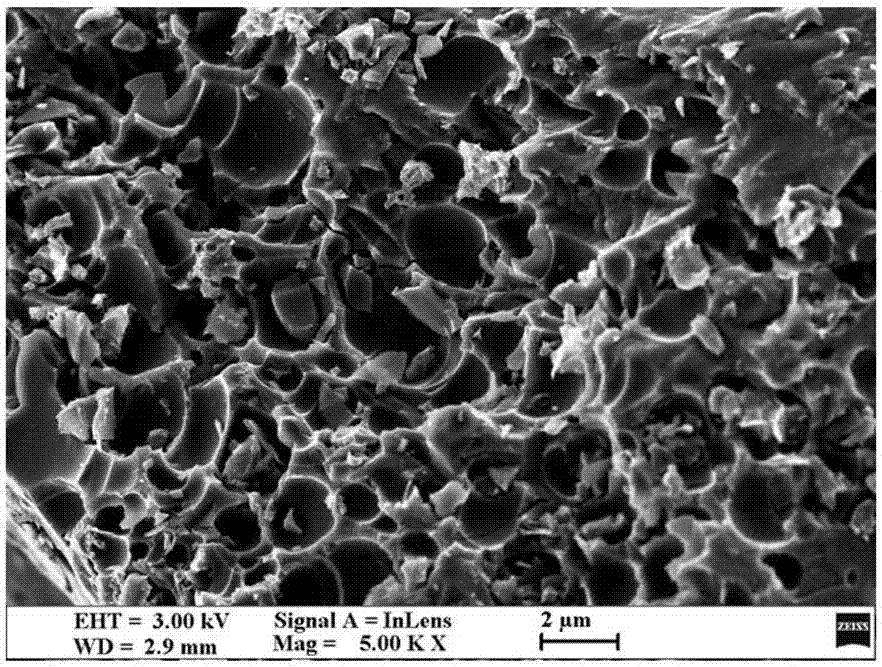

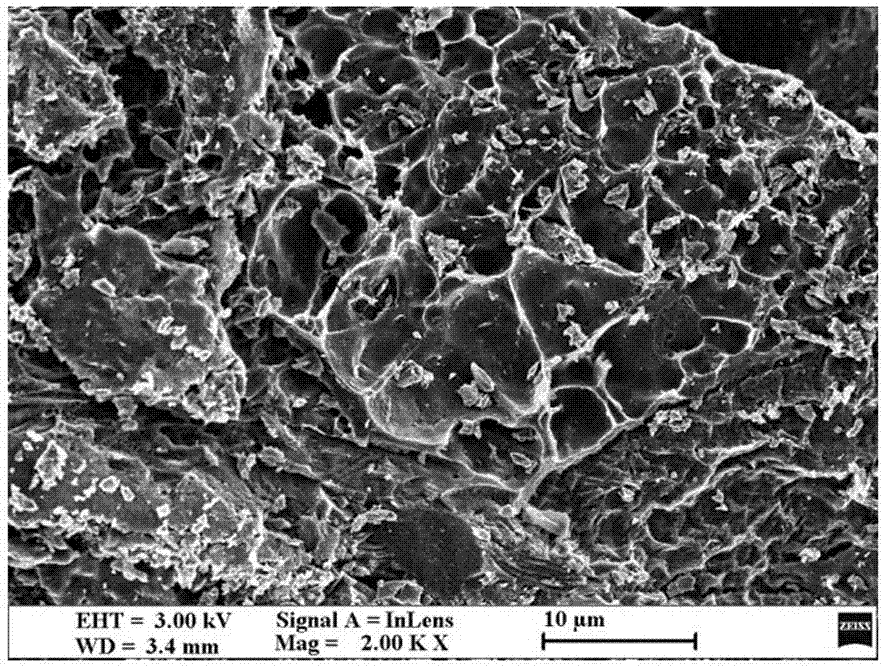

[0028] The preparation method of konjac flour base porous carbon material of the present invention is as follows:

[0029] (1) Preparation of pre-carbonized products: put the konjac flour raw material into a graphite crucible, place it in a resistance furnace, and heat it anaerobically at 200-500 °C (preferably 300-500 °C) at a heating rate of 3-10 °C min -1 , preferably 3~5 ℃ min -1 ; The holding time is 1~3 h, and after fully pyrolyzing under normal pressure, it is lowered to room temperature to obtain the pre-carbonized product;

[0030] (2) Preparation of activated precursor mixture: mix the obtained pre-carbonized product with an activator, and the mass ratio of the activator to the pre-carbonized product is 1:30~30:1, preferably 1:1~9:1 ; Add deionized water, stir for 5 h in the state of the solution, and dry the solution at 60 °C to constant weight to obtain the activated precursor mixture;

[0031] (3) Preparation of konjac flour-based porous carbon material: put th...

Embodiment 1

[0038] (1) Put 1.5 g of konjac flour raw material into a 20 mL graphite crucible, place it in a resistance furnace, and heat it anaerobically at 400 °C with a heating rate of 5 °C min -1 , the holding time is 1 h, and after fully pyrolyzing under normal pressure, it is cooled to room temperature with the furnace to obtain a pre-carbonized product, which is ground in a mortar and put into a desiccator for use;

[0039] (2) Take 1.2 g of potassium hydroxide and 0.4 g of the pre-carbonized product obtained in (1) (mass ratio is 3:1), put them into a beaker, add 20 mL of deionized water, and carry out magnetic stirring for 5 After h, it was poured into an evaporating dish, dried in an oven at 60 °C to constant weight to obtain a black solid powder, and then ground to obtain an activated precursor mixture;

[0040] (3) Put 1.6 g of the activated precursor mixture in (2) into a 20 mL graphite crucible, place in a resistance furnace, and heat anaerobically at 700 °C with a heating ra...

Embodiment 2

[0042] (1) Put 1.5 g of konjac flour raw material into a 20 mL graphite crucible, place it in a resistance furnace, and heat it anaerobically at 500 °C with a heating rate of 4 °C min -1 , the holding time is 1 h, and after fully pyrolyzing under normal pressure, it is cooled to room temperature with the furnace to obtain a pre-carbonized product, which is ground in a mortar and put into a desiccator for use;

[0043] (2) Take 2.0 g of potassium hydroxide and 0.4 g of the pre-carbonized product obtained in (1) (mass ratio: 5:1), put them into a beaker, add 20 mL of deionized water, and carry out magnetic stirring for 5 After h, it was poured into an evaporating dish, dried in an oven at 60 °C to constant weight to obtain a black solid powder, and then ground to obtain an activated precursor mixture;

[0044] (3) Put 2.4 g of the activated precursor mixture in (2) into a 20 mL graphite crucible, place in a resistance furnace, and heat anaerobically at 800 °C with a heating rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com