Method for preparing gradient directional porous cement based on two-phase pore former system freezing molding technology

A pore-forming agent and system technology, which is applied in the field of porous cement preparation, can solve the problems of high-temperature heat treatment and complicated preparation process, and achieve the effect of avoiding the collapse and cracking of the pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

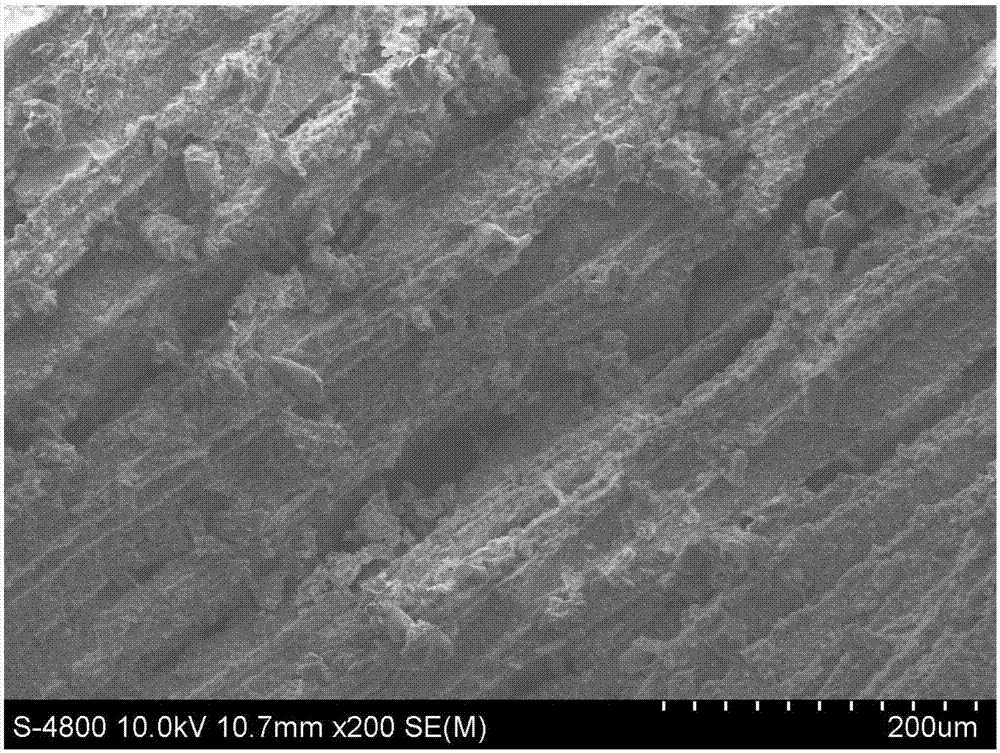

[0043] A method for preparing gradient oriented porous cement based on two-phase pore-forming agent system freeze molding technology, comprising the following steps:

[0044] (1) Preparation of cement mixture slurry based on the two-phase pore-forming agent system: Weigh all the raw materials according to the ratio in Table 1, and add the dispersant (polyvinylpyrrolidone) and binder (ethyl cellulose) to the two-phase Porogen system (TBA-H 2 In (0), mechanically stir for 1 hour to obtain a uniformly dispersed organic mixture, then put the organic mixture and Portland cement powder into a ball mill for ball milling for 12 hours, and obtain a uniformly dispersed cement-based mixed slurry after vacuum degassing;

[0045] (2) Preparation of frozen cement-based body: inject the above-mentioned cement-based mixed slurry into a self-made directional freezing mold for directional freezing and shaping. The freezing temperature is -40°C and the freezing time is 0.5h. It is carefully rel...

Embodiment 2

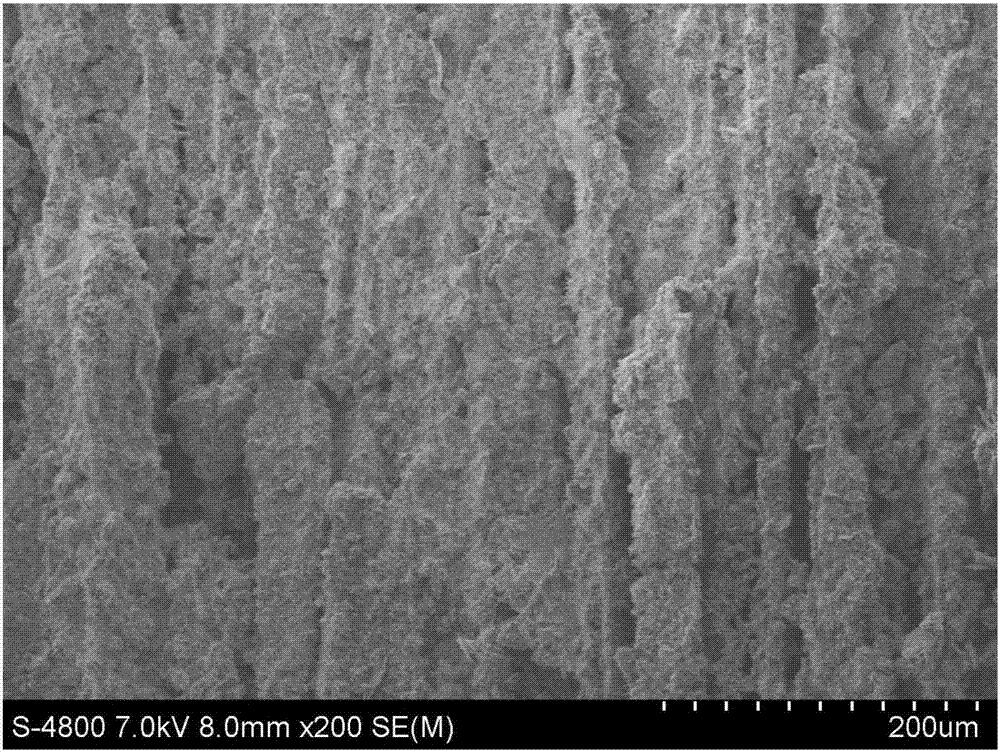

[0049] A method for preparing gradient oriented porous cement based on two-phase pore-forming agent system freeze molding technology, comprising the following steps:

[0050] (1) Preparation of cement mixture slurry based on the two-phase pore-forming agent system: Weigh all the raw materials according to the ratio in Table 1, and add the dispersant (gum arabic) and binder (polyethylene) to the two-phase pore-forming agent system (TBA-H 2 (0), stir mechanically for 2 hours to obtain a uniformly dispersed organic mixed solution, then put the organic mixed solution and composite Portland cement powder into a ball mill for ball milling for 24 hours, and obtain a uniformly dispersed cement-based mixed slurry after vacuum degassing ;

[0051] (2) Preparation of frozen cement-based body: inject the above-mentioned cement-based mixed slurry into a self-made directional freezing mold for directional freezing and shaping. The freezing temperature is -60°C and the freezing time is 1 h....

Embodiment 3

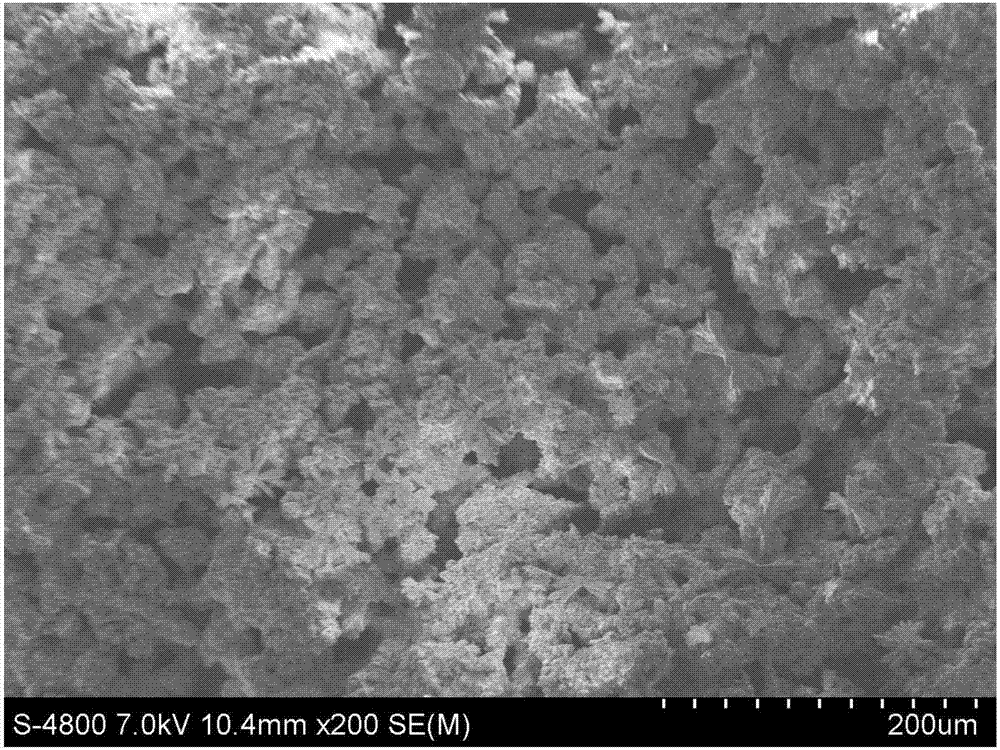

[0055] A method for preparing gradient oriented porous cement based on two-phase pore-forming agent system freeze molding technology, comprising the following steps:

[0056] (1) Preparation of cement mixture slurry based on two-phase pore-forming agent system: Weigh all raw materials according to the ratio in Table 1, add dispersant (polyethylene glycol) and binder (polyvinyl butyral) to the two-phase pore former system (TBA-H 2 In (0), mechanically stir for 1.5h to obtain a uniformly dispersed organic mixed solution, then put the organic mixed solution and pozzolanic cement powder into a ball mill for ball milling for 48h, and obtain a uniformly dispersed cement-based mixed slurry after vacuum degassing;

[0057] (2) Preparation of frozen cement-based body: inject the above-mentioned cement-based mixed slurry into a self-made directional freezing mold for directional freezing and shaping. The freezing temperature is -80°C and the freezing time is 2 hours. Carefully eject fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com