High-energy density material and synthesis method thereof

A technology with high energy density and synthesis method, applied in the field of new high energy density materials and their synthesis, can solve the problems of complex process, complex synthesis process and high production cost, and achieve simple synthesis method, low process cost and excellent detonation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

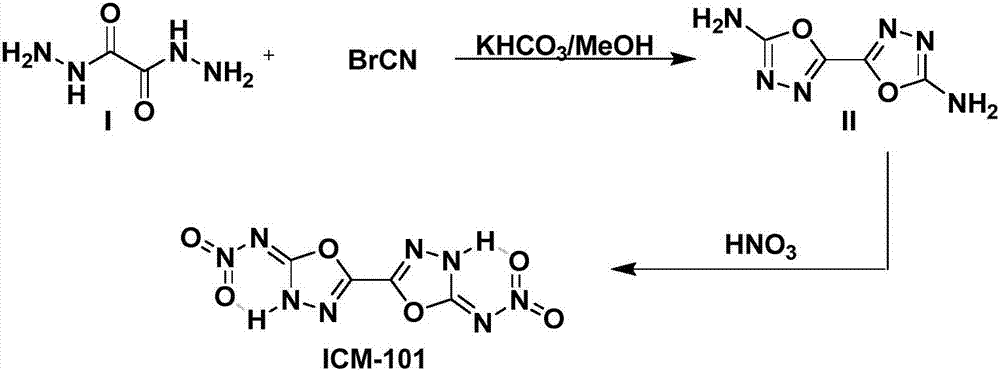

[0030] A method for synthesizing high energy density materials, comprising the steps of:

[0031] a) Preparation of [2,2'-bi(1,3,4-oxadiazole)]-5,5'-diamine

[0032] At -20°C, add oxalodihydrazide (I) and potassium bicarbonate into the solvent acetonitrile and stir, then add cyanogen bromide in batches, after the addition, control the temperature of the reaction system at -20°C and keep it for 2 days. Add 10 times the volume of water used in acetonitrile to the reaction and continue to stir for 6h, filter and wash with a small amount of water, and dry to obtain [2,2'-bi(1,3,4-oxadiazole)]-5,5'-di Amine (II).

[0033] The molar ratio of oxalodihydrazine to cyanogen bromide and potassium bicarbonate is 1:2:2

[0034] b) Preparation of [2,2'-bi(1,3,4-oxadiazole)]-5,5'-dinitroamine

[0035] Nitrate [2,2'-linked (1,3,4-oxadiazole)]-5,5'-diamine (II) in the nitration system tetrafluoroboronitrate to obtain [2,2'- Bi(1,3,4-oxadiazole)]-5,5'-dinitroamine (ICM-101), the specific st...

Embodiment 2

[0039] A method for synthesizing high energy density materials, comprising the steps of:

[0040] a) Preparation of [2,2'-bi(1,3,4-oxadiazole)]-5,5'-diamine

[0041] At 50°C, add oxalodihydrazine (I) and sodium bicarbonate into the solvent tetrahydrofuran and stir, then add cyanogen bromide in batches, and control the temperature of the reaction system at 50°C after the addition, and keep it for 10 hours. Add 1 volume of THF water to the reaction and continue to stir for 2h, filter and wash with a small amount of water, and dry to obtain [2,2'-bi(1,3,4-oxadiazole)]-5,5'-di Amine (II).

[0042] The molar ratio of oxalodihydrazine to cyanogen bromide and sodium bicarbonate is 1:10:10

[0043] b) Preparation of [2,2'-bi(1,3,4-oxadiazole)]-5,5'-dinitroamine

[0044] Nitrate [2,2'-bi(1,3,4-oxadiazole)]-5,5'-diamine (II) in nitric acid / acetic anhydride in the nitration system to obtain [2,2'- Bi(1,3,4-oxadiazole)]-5,5'-dinitroamine (ICM-101), the specific steps are:

[0045][2,...

Embodiment 3

[0048] A method for synthesizing high energy density materials, comprising the steps of:

[0049] a) Preparation of [2,2'-bi(1,3,4-oxadiazole)]-5,5'-diamine

[0050] Under the condition of 30°C, oxalic dihydrazide (I) and potassium bicarbonate were added to the solvent toluene and stirred, and cyanogen bromide was added in batches. After the addition, the temperature of the reaction system was controlled to be 30°C and kept for 1 day. Add 5 times the volume of toluene to the reaction water and continue to stir for 4h, filter and wash with a small amount of water, and dry to obtain [2,2'-bi(1,3,4-oxadiazole)]-5,5'-bis Amine (II).

[0051] The molar ratio of oxalic dihydrazide to cyanogen bromide and potassium bicarbonate is 1:5:5

[0052] b) Preparation of [2,2'-bi(1,3,4-oxadiazole)]-5,5'-dinitroamine

[0053] Nitration of [2,2'-bi(1,3,4-oxadiazole)]-5,5'-diamine (II) in the nitration system sulfur trioxide / nitric acid yields [2,2' -Bi(1,3,4-oxadiazole)]-5,5'-dinitroamine (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com