Self-curing polyphenylene ether resin composition and preparation method for heavy-duty anti-corrosion coatings

A polyphenylene ether resin, self-curing technology, applied in anti-corrosion coatings, polyether coatings, coatings, etc., to achieve excellent boiling water resistance and physical and mechanical properties, excellent physical and mechanical properties, outstanding effects of seawater resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

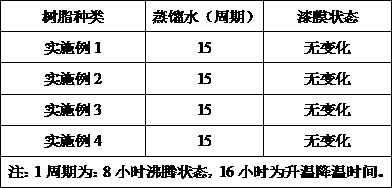

Examples

Embodiment 1

[0018] Add 100 parts of polyphenylene ether resin (low molecular weight double-terminated hydroxyl polyphenylene ether resin, NORYL SA90 resin, SABIC Innovative Plastics Co., Ltd., molecular weight 1800g / mol, hydroxyl equivalent 840 g / mol, the same below) to 100 parts of toluene , prepare a polyphenylene ether resin solution; under magnetic stirring, add 10 parts of bis(acetylacetonate) diisopropyl titanate dropwise to the above polyphenylene ether solution; Dibutyltin acid, at 30 o C temperature for 0.5h, after cooling at room temperature, the self-curing polyphenylene ether resin can be obtained.

[0019] Described low molecular weight two-terminal hydroxyl polyphenylene ether resin, its structural formula is:

[0020] .

Embodiment 2

[0022] Add 100 parts of polyphenylene ether resin to 200 parts of xylene to prepare a polyphenylene ether resin solution; under magnetic stirring, add 20 parts of diisopropyl di(acetylacetonate) titanate dropwise to the above polyphenylene ether solution; After the dropwise addition, add 1.2 parts of dibutyltin dilaurate dropwise, at 50 o C for 1 h, and after cooling at room temperature, a self-curing polyphenylene ether resin can be obtained.

Embodiment 3

[0024] Add 120 parts of polyphenylene ether resin to 400 parts of xylene to prepare a polyphenylene ether resin solution; under magnetic stirring, add 60 parts of bis(ethyl acetoacetate) diisopropyl titanate dropwise to the above polyphenylene ether solution ; After the dropwise addition, add 1.2 parts of dibutyltin dilaurate dropwise, at 90 o C for 3 hours, and after cooling at room temperature, a self-curing polyphenylene ether resin can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com