Light calcium-coated fiber filling for papermaking as well as preparation method and application of light calcium-coated fiber filling

A fiber filler and coating technology, applied in the field of papermaking, can solve the problems of paper strength, high white water concentration, low retention effect, etc., and achieve the effects of improving tensile strength, reducing white water concentration, and saving water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

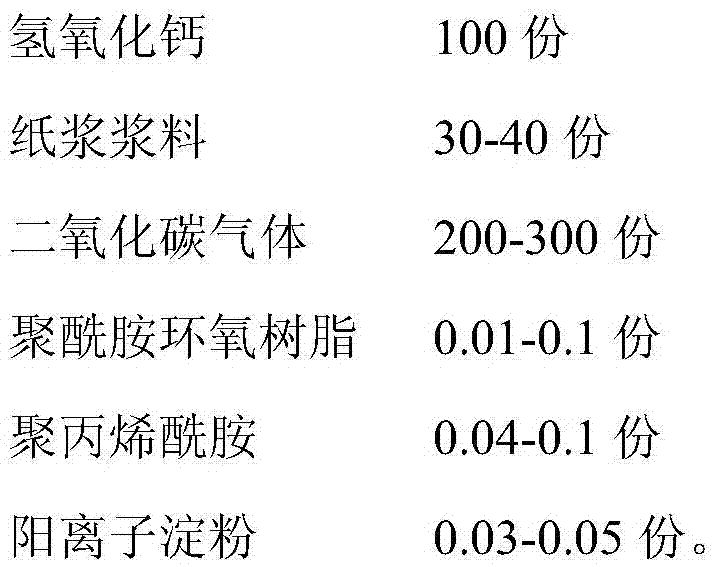

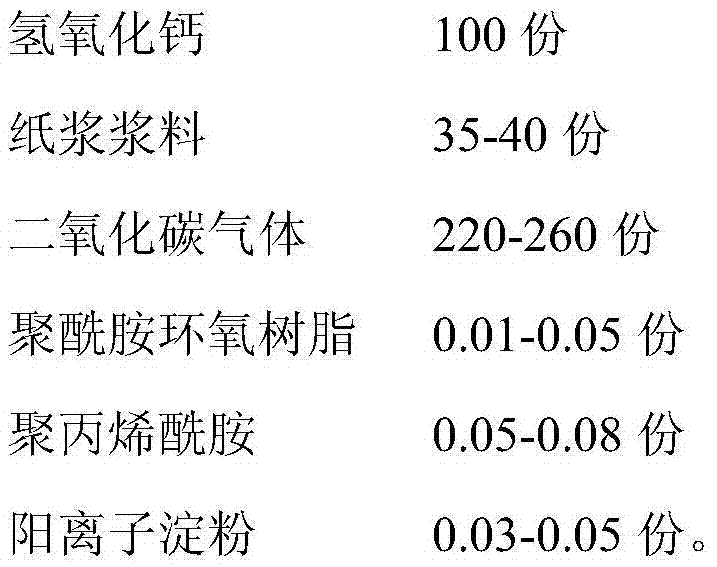

[0051]Example 1 Preparation of Light Calcium Coated Fiber Filler for Papermaking

[0052] Step 1: Make the pulp slurry into coniferous pulp: hardwood pulp = 1:4 pulp, and a mixed pulp with a beating degree of 400SR. Prepare 5kg of pulp slurry solution with a pulp concentration of 0.8%, and add them to the reaction kettle in turn Add 1g of polyamide epoxy resin solution with a concentration of 5%, 16.5g of a polyacrylamide solution with a concentration of 0.3%, and 5g of a cationic starch solution with a concentration of 0.8%, and stir for 20min at a speed of 450r / min to make it mix uniform.

[0053] Step 2: Add 500g of calcium hydroxide solution with a solid content of 20% to the fiber mixing component in step 1, the rotation speed is 500r / min, the pressure is 0.3Mpa, stir for 30min to make it evenly mixed, and drop to normal pressure, The rotating speed is 300r / min.

[0054] Step 3: Infuse gas with a carbon dioxide concentration of 45%, and fully carbonize at about 18°C±2°C...

Embodiment 2

[0055] Example 2 Preparation of Light Calcium Coated Fiber Filler for Papermaking

[0056] Step 1: Make the pulp slurry into coniferous pulp: hardwood pulp = 1:4 pulp, a mixed pulp with a beating degree of 400SR, prepare 3.75kg of pulp slurry solution with a pulp concentration of 0.8%, and add it to the reaction kettle 1 g of polyamide epoxy resin solution with a concentration of 5%, 16.5 g of a polyacrylamide solution with a concentration of 0.3%, and 5 g of a cationic starch solution with a concentration of 0.8% were added successively, and stirred at a speed of 450 r / min for 20 min to make it well mixed.

[0057] Step 2: Add 500g of calcium hydroxide solution with a solid content of 20% to the fiber mixing component in step 1, the rotation speed is 500r / min, the pressure is 0.3Mpa, stir for 30min to make it evenly mixed, and drop to normal pressure, The rotating speed is 300r / min.

[0058] Step 3: Infuse gas with a carbon dioxide concentration of 45%, and fully carbonize ...

Embodiment 3

[0059] Embodiment 3 Dynamic water filtration experiment:

[0060] 3.1 Experimental samples:

[0061] Paste light calcium filler (brand name: SSTL-PCCGZ40) and fiber filler coated with light calcium produced by Dongsheng New Materials (Shandong) Co., Ltd. were selected.

[0062] 3.2 Experimental conditions:

[0063] Pulp ratio: softwood pulp 20% + broadleaf pulp 80% (mixed pulp beating degree 400SR)

[0064] Surabaya paste calcium filler, light calcium calcium coated fiber filler, CPAM retention aid;

[0065] Experimental process: slurry (75%) + filler (25%) + CPAM (200ppm);

[0066] (The above additions are dry / dry)

[0067] The design is based on the online concentration of 0.6% (paper material 3g is absolutely dry), the design speed is 750 rpm, the weighed pulp is stirred for 5 seconds, the filler is stirred for 5 seconds, then the retention aid is added and stirred for 5 seconds, and the drain valve is opened for 10 seconds. Take 100ml of white water under the net, tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com