Oxygen-doped molybdenum disulfide thermoelectric material preparation method

A technology of molybdenum disulfide and thermoelectric materials, which is applied in the manufacture/processing of thermoelectric devices, molybdenum sulfide, etc., can solve the problems of high thermal conductivity and high resistance, and achieve the effects of low thermal conductivity, increased electrical conductivity, and increased ZT value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

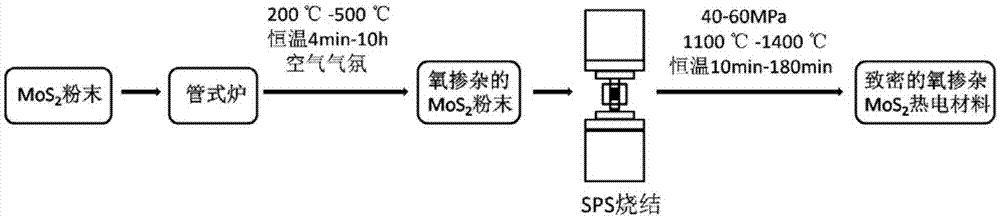

Method used

Image

Examples

Embodiment 1

[0040] Oxygen-doped molybdenum disulfide thermoelectric material, the specific preparation method is as follows:

[0041] (1) Take 5g molybdenum disulfide powder and place it in a corundum boat, put it into the quartz tube of the horizontal tube furnace, the diameter of the quartz tube is 50mm, and the length is 1m;

[0042] (2) Purge the quartz tube with argon gas for 2 hours, adjust the flow rate of argon to 76 sccm, increase the heating rate at 5°C / min to 300°C, then switch the gas to air at a flow rate of 100 sccm, keep the temperature for 0.5h, and finally switch the gas to argon Gas, flow rate is 76sccm, began to cool down naturally;

[0043] (3) The powder sample obtained in step (2) is put into a graphite mold with a diameter of 12.7 mm, put into an SPS sintering furnace, pressurized at 50 MPa, and evacuated until the vacuum degree is less than 5 Pa. Then, the current is applied to raise the temperature for sintering, and the temperature rises to about 20 minutes. 130...

Embodiment 2

[0045] Oxygen-doped molybdenum disulfide thermoelectric material, the specific preparation method is as follows:

[0046] (1) Weigh 5g of molybdenum disulfide powder, place it in a corundum boat, and put it into a quartz tube of a horizontal tube furnace.

[0047] (2) Purge the quartz tube with argon gas for 2 hours, adjust the flow rate of argon to 76 sccm, increase the temperature at a rate of 5°C / min to 300°C, then switch the gas to air at a flow rate of 100 sccm, keep the temperature constant for 5 hours, and finally switch the gas to argon , flow rate is 76sccm, begins to cool down naturally.

[0048] (3) The powder sample obtained in step (2) is put into a graphite mold with a diameter of 12.7 mm, put into an SPS sintering furnace, pressurized at 50 MPa, and evacuated until the vacuum degree is less than 5 Pa. Then, the current is applied to raise the temperature for sintering, and the temperature rises to about 20 minutes. 1300°C, keep warm for 2 hours, then release th...

Embodiment 3

[0050] Oxygen-doped molybdenum disulfide thermoelectric material, the specific preparation method is as follows:

[0051] (1) Weigh 5g of molybdenum disulfide powder, place it in a corundum boat, and put it into a quartz tube of a horizontal tube furnace.

[0052] (2) Purge the quartz tube with argon gas for 2 hours, adjust the flow rate of argon to 76 sccm, increase the heating rate at 5°C / min to 300°C, then switch the gas to air at a flow rate of 100 sccm, keep the temperature constant for 10 hours, and finally switch the gas to argon , flow rate is 76sccm, begins to cool down naturally.

[0053] (3) The powder sample obtained in step (2) is put into a graphite mold with a diameter of 12.7 mm, put into an SPS sintering furnace, pressurized at 50 MPa, and evacuated until the vacuum degree is less than 5 Pa. Then, the current is applied to raise the temperature for sintering, and the temperature rises to about 20 minutes. 1300°C, keep warm for 2 hours, then release the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com