Pickling method of basked cucumber peel for reducing nitrite content

A technology of nitrite and cucumber peel is applied in the directions of bacteria and food ingredients used in food preparation as antioxidants, climate change adaptation, etc. Influence, low nitrite removal rate and other problems, to achieve the effect of retaining nutrients, easy control of production conditions, and enhancing reducing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

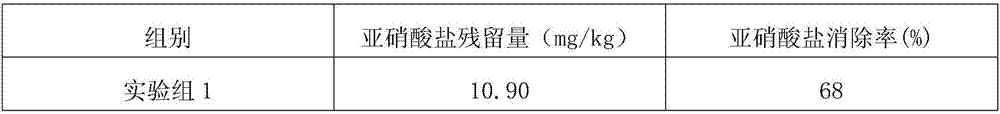

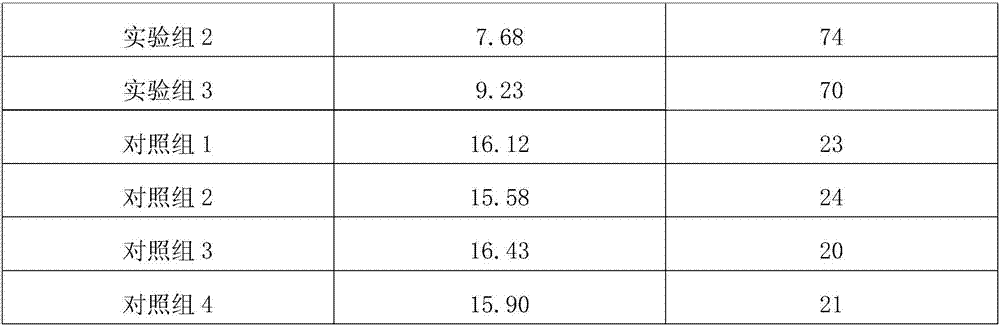

Embodiment 1

[0025] A kind of sun-dried cucumber skin pickling method that reduces nitrite content in the present embodiment comprises the following steps:

[0026] (1) Select white-skinned cucumbers with greenish-white skin that has not turned yellow and seeds that have not hardened, washed, cut into cucumber strips with a length of 3-6cm, a width of 0.3-0.8cm, and a thickness of 1-2cm. After the cucumber strips were blanched in steam at 90°C for 90 seconds, they were placed in the sun and dried until the weight was 38% of the weight of the cucumber strips to obtain sun-dried cucumber strips for later use;

[0027] (2) Mix the above-mentioned sun-dried cucumber strips with 0.5% of the weight of the sun-dried cucumber strips with Lactobacillus plantarum, 0.01% ferrous gluconate, 0.05% zinc gluconate, 0.5% salt and 0.3% white sugar. Sealed and pickled for 15 days to get pickled cucumber skin once;

[0028] (3) Combine the above-mentioned primary pickled cucumber skin with the grape seed ex...

Embodiment 2

[0031] A kind of sun-dried cucumber skin pickling method that reduces nitrite content in the present embodiment comprises the following steps:

[0032] (1) Select white-skinned cucumbers with greenish-white skin that has not turned yellow and seeds that have not hardened, washed, cut into cucumber strips with a length of 3-6cm, a width of 0.3-0.8cm, and a thickness of 1-2cm. After the cucumber strips were blanched in steam at 100°C for 60 seconds, they were placed in the sun and dried until the weight was 48% of the weight of the cucumber strips to obtain sun-dried cucumber strips for later use;

[0033] (2) Mix the above-mentioned sun-dried cucumber strips with 1% of the weight of the sun-dried cucumber strips, Lactobacillus plantarum, 0.03% ferrous gluconate, 0.08% zinc gluconate, 1.5% salt and 0.8% white sugar, and mix them evenly at 35°C. Sealed and pickled for 10 days to obtain pickled cucumber skin once;

[0034] (3) Combine the above-mentioned primary pickled cucumber ...

Embodiment 3

[0037] A kind of sun-dried cucumber skin pickling method that reduces nitrite content in the present embodiment comprises the following steps:

[0038] (1) Select white-skinned cucumbers with greenish-white skin that has not turned yellow and seeds that have not hardened, washed, cut into cucumber strips with a length of 3-6cm, a width of 0.3-0.8cm, and a thickness of 1-2cm. The cucumber strips are blanched in steam at 95°C for 70 seconds, and then placed in the sun to dry until the weight is 40% of the weight of the cucumber strips to obtain sun-dried cucumber strips, which are set aside;

[0039] (2) Mix the above-mentioned sun-dried cucumber strips with 0.8% of the weight of the sun-dried cucumber strips with Lactobacillus plantarum, 0.03% ferrous gluconate, 0.06% zinc gluconate, 1% salt and 0.5% white sugar, and mix them evenly at 30°C. Sealed and pickled for 13 days to get pickled cucumber skin once;

[0040] (3) Combine the above-mentioned primary pickled cucumber skin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com