Method of marking medical interventional equipment

A marking method and equipment technology, which is applied to other medical equipment, pharmaceutical equipment, catheters, etc., can solve the problems of reducing the breaking force of the pipe, high cost, and the inner diameter of the mandrel placement equipment is reduced, so as to achieve good safety, reduce injuries, Mark solid and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

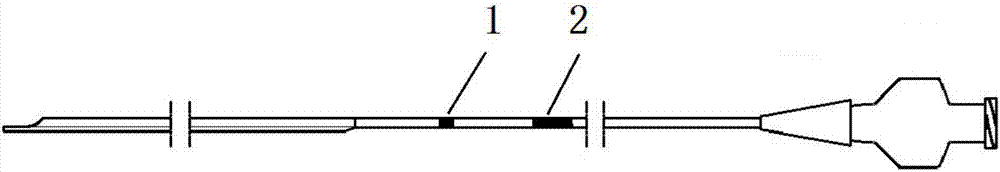

[0025] Example 1: Labeling Intravascular Catheters

[0026] 1. Materials

[0027] 1. Intravascular catheter: the material is polyimide (PI)

[0028] 2. Marking wire: polyethylene terephthalate (PET) suture with a diameter of 0.007mm

[0029] 3. Liquid liquid polyurethane: ChronoFlex from AdvanSource Biomaterials, UK 8% solids liquid polyurethane

[0030] 2. Method

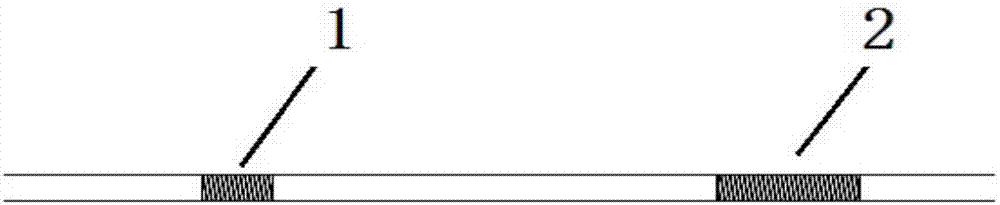

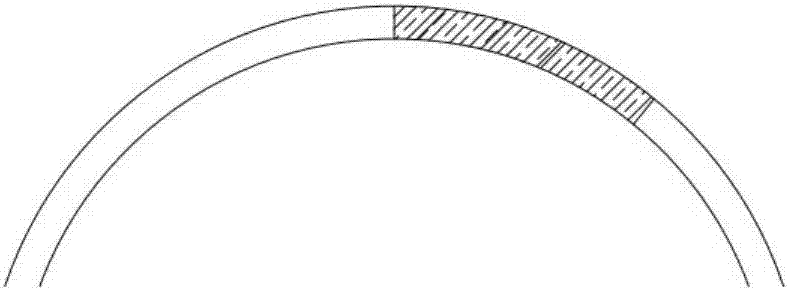

[0031] Select a steel braze suitable for the inner diameter of the catheter, pass the steel braze into the catheter, fix the proximal end of the catheter and the steel braze on the rotary tooling, measure the marked position, and select a polyethylene terephthalate (PET) suture with a diameter of 0.007mm , heat the head end of the suture, iron it on the surface of the medical interventional equipment to be marked (1), rotate the catheter forward, wrap the suture tightly around the catheter to a marked length of 2 mm, heat the end of the suture, and iron it off While suturing the thread, the end is hot on the ...

Embodiment 2

[0036] 1. Materials

[0037] 1. Metal hypotube

[0038] 2. Marking wire: polyethylene terephthalate (PET) suture with a diameter of 0.23 mm

[0039] 3. Liquid liquid polyurethane: ChronoFlex from AdvanSource Biomaterials, UK 8% solids liquid polyurethane

[0040] 2. Method

[0041] Select a steel drill suitable for the inner diameter of the hypotube, and insert the steel drill into the metal hypotube, fix the proximal end of the hypotube and the steel drill on the rotary tooling, measure the marked position, and use polyethylene terephthalate with a diameter of 0.23 mm Diester (PET) sutures are tightly wound in the same direction of rotation (forward) at the position to be marked on the hypotube to achieve a marking length of 15 mm; the needle tube is filled with liquid liquid polyurethane, and a 14G dispensing stainless steel needle is selected. Start the dispensing machine with a pressure of 20psi, and apply liquid polyurethane on the marked position. After dispensing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com