A kind of preparation method of sodium chloride salt brick capable of releasing negative oxygen ions under light

A negative oxygen ion and sodium chloride technology, which is applied in the field of NaCl crystal material application and production, can solve the problems that hinder the popularization and price of negative oxygen ion equipment, and achieve the effect of improving the local environment and improving the health index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

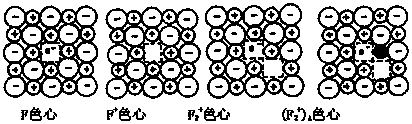

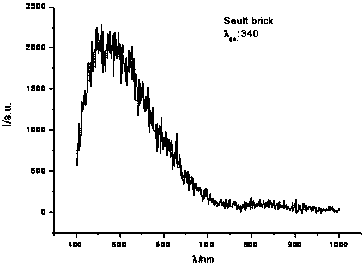

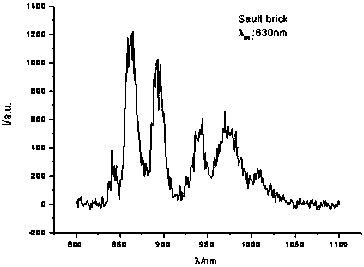

Method used

Image

Examples

Embodiment Construction

[0025] as Figure 4 The preparation process of salt bricks for the salt steam room shown is taken as an example, and the preparation process of its products is quantitatively described:

[0026] 1. Take 1kg of refined salt, put it into a corundum crucible and move it into a high-temperature furnace;

[0027] 2. After heating to 500°C within 3 hours, cool down to 300°C within 2 hours, and then cool down to room temperature naturally;

[0028] 3. Take out the crucible from the furnace, put the material in the crucible into a ball mill and grind for 30 minutes, and then pass through a 80-mesh sieve;

[0029] 4. Collect the sieved material and move it into the mold, pressurize to 40MPa and keep it for 10min, then take it out, and get such Figure 4 "Pre-fired salt brick" in the displayed style;

[0030] 5. Move the "pre-fired salt brick" into the high-temperature furnace again, raise the temperature to 300°C within 10 minutes and keep the temperature constant for 1 hour, contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com