Humidity-adjustable tile and production method thereof

A production method and ceramic tile technology, which is applied in the field of ceramic products, can solve the problems of poor flexural strength of tiles, negligible flexural strength, and small humidity control capacity, etc., so as to improve moisture release performance, avoid poor flexural strength, and fast drying speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

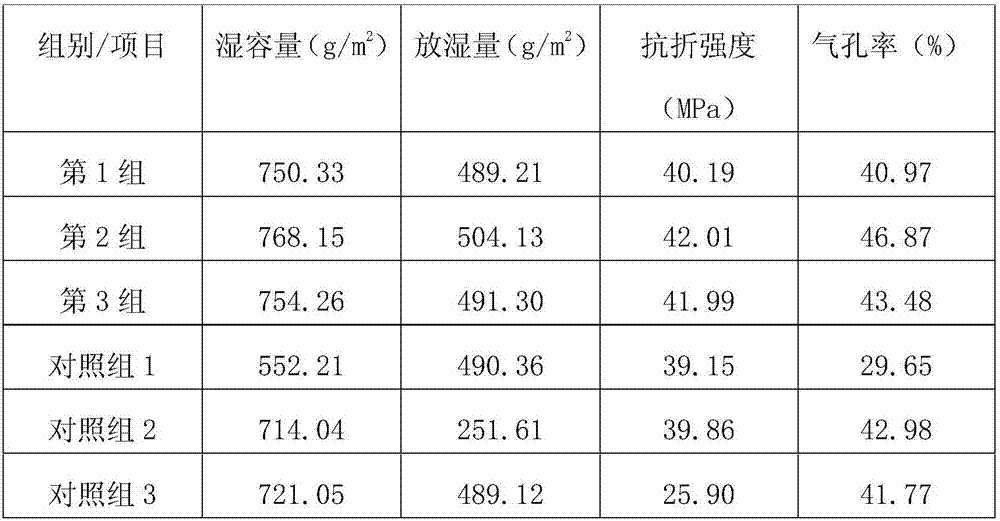

Examples

Embodiment 1

[0029] In this embodiment, an adjustable humidity ceramic tile is made of the following raw materials in parts by weight: 30 parts of diatomite, 20 parts of kaolin, 19 parts of clay, 15 parts of zeolite, 10 parts of quartz sand, 11 parts of vermiculite, guar 8 parts of soybean powder, 5 parts of sodium carboxymethyl cellulose, 1 part of calcium chloride, 5 parts of ammonium bicarbonate, 0.8 parts of magnesium oxide and 0.3 parts of aluminum oxide. The loss on ignition of the above-mentioned kaolin and clay are both 9 wt%.

[0030] In this embodiment, a method for manufacturing an adjustable humidity tile comprises the following steps:

[0031] (1) take each raw material by above-mentioned parts by weight;

[0032] (2) Pulverize diatomite, kaolin, clay, zeolite, quartz sand and vermiculite, and pass through an 80-mesh sieve to obtain powder;

[0033] (3) Mix sodium carboxymethyl cellulose, calcium chloride, ammonium bicarbonate, magnesium oxide and aluminum oxide with the abo...

Embodiment 2

[0036] In this embodiment, an adjustable humidity ceramic tile is made of the following raw materials in parts by weight: 40 parts of diatomite, 25 parts of kaolin, 23 parts of clay, 19 parts of zeolite, 14 parts of quartz sand, 16 parts of vermiculite, guar 14 parts of soybean powder, 9 parts of sodium carboxymethyl cellulose, 4 parts of calcium chloride, 8 parts of ammonium bicarbonate, 1.5 parts of magnesium oxide and 0.7 parts of aluminum oxide. The loss on ignition of the above-mentioned kaolin and clay are both 15 wt%.

[0037] In this embodiment, a method for manufacturing an adjustable humidity tile comprises the following steps:

[0038] (1) take each raw material by above-mentioned parts by weight;

[0039] (2) Pulverize diatomite, kaolin, clay, zeolite, quartz sand and vermiculite, and pass through a 90-mesh sieve to obtain powder;

[0040] (3) Mix sodium carboxymethyl cellulose, calcium chloride, ammonium bicarbonate, magnesium oxide and aluminum oxide with the a...

Embodiment 3

[0043] In this embodiment, an adjustable humidity tile is made of the following raw materials in parts by weight: 35 parts of diatomite, 22 parts of kaolin, 21 parts of clay, 17 parts of zeolite, 12 parts of quartz sand, 14 parts of vermiculite, guar 11 parts of soybean powder, 7 parts of sodium carboxymethyl cellulose, 3 parts of calcium chloride, 6 parts of ammonium bicarbonate, 1 part of magnesium oxide and 0.5 parts of aluminum oxide. The loss on ignition of the above-mentioned kaolin and clay are both 12 wt%.

[0044] In this embodiment, a method for manufacturing an adjustable humidity tile comprises the following steps:

[0045] (1) take each raw material by above-mentioned parts by weight;

[0046] (2) Pulverize diatomite, kaolin, clay, zeolite, quartz sand and vermiculite, and pass through a 85-mesh sieve to obtain powder;

[0047] (3) Mix sodium carboxymethyl cellulose, calcium chloride, ammonium bicarbonate, magnesium oxide and aluminum oxide with the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com