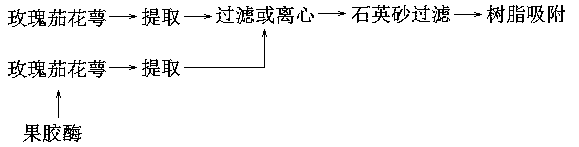

Pretreatment method before column adsorption and purification of roselle pigment extract

The technology of extracting liquid and roselle is applied in the field of pretreatment before the adsorption and purification of roselle pigment extract liquid, which can solve the problems of time-consuming, reduced solubility, and reduced product purity, so as to avoid clogging of resin column and prevent reprecipitation. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Below in conjunction with technical scheme, describe concrete production steps of the present invention in detail:

[0018] (1) Pigment extraction: extract 50 g of dried roselle calyx and 750 mL of distilled water (mass volume ratio 1:15), extract in a constant temperature water bath at 50°C for 2 hours, and pour out the extract.

[0019] (2) Filtration: filter the extract with ordinary filter paper, and collect the filtrate.

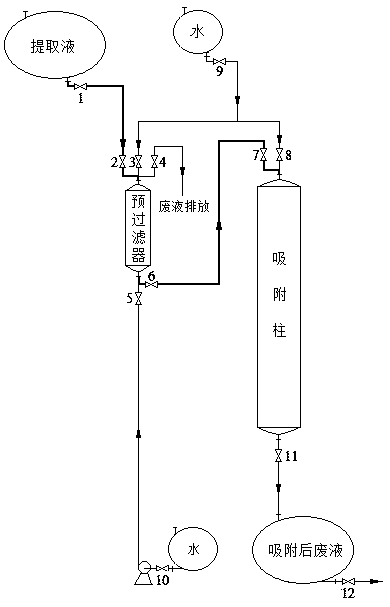

[0020] (3) Quartz sand filtration and resin adsorption of pigments: the size of the quartz sand filter is 1×15 cm, and half of the height of the column is added to the quartz sand. Take an appropriate amount of AB-8 adsorption resin, soak it in distilled water first, wash it with distilled water until the liquid is clear, then soak it with 95% ethanol for 4 hours, wash it with distilled water until it is not cloudy, and pour it into a 1×100cm adsorption column. Connect the quartz sand filter and the adsorption column in series, as attached fig...

Embodiment 2

[0023] Same as Example 1, except that in step (1), 0.1 g of pectinase is added together with the material, and the enzyme activity of pectinase is 30,000 U / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com