High-strength high-modulus graphene/nylon 6 fiber and preparation method

A high-strength, high-modulus, graphene technology, applied in fiber chemical characteristics, melt spinning, rayon manufacturing, etc., can solve problems such as uneven dispersion, increased screw torque, and clogging, and achieve good bonding and avoid clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

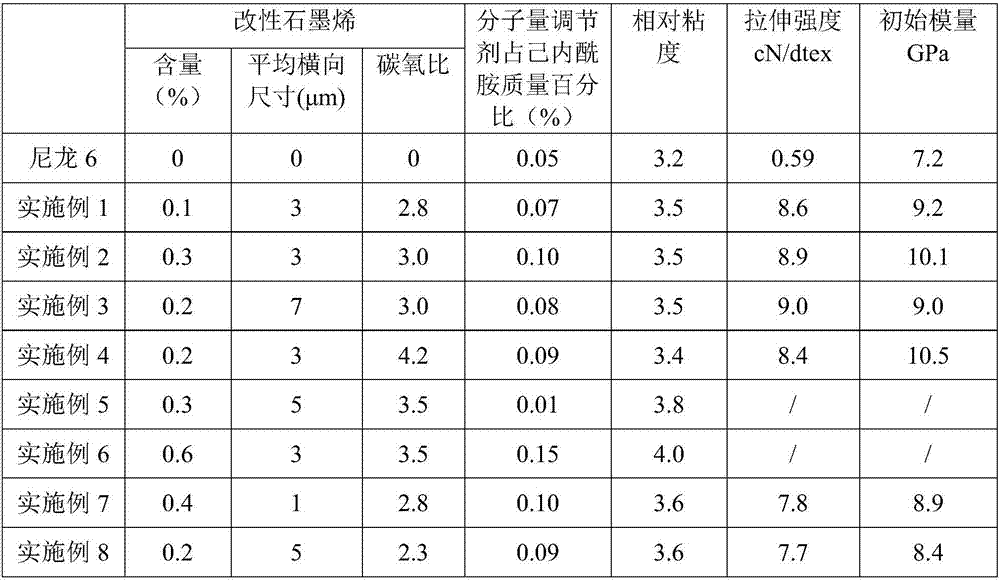

Embodiment 1

[0019] Add 0.1 parts by mass of single-layer graphene with a carbon-to-oxygen ratio of 2.8 and a lateral size of 3 μm, 0.07 parts by mass of a molecular weight regulator, and 10 parts by mass of deionized water into 100 parts by mass of caprolactam melt, at 80 ° C at a high speed (400rpm) stirring and mixing to form a dispersion; under the protection of nitrogen, the above dispersion was heated to 250°C in a polycondensation reactor, reacted at 0.7Mpa for 3 hours, and then reacted under vacuum for 4 hours to obtain a polycondensate melt; Then the polymer melt is water-cooled and granulated to obtain the graphene / nylon 6 nanocomposite material. The obtained graphene / nylon 6 nanocomposite material is uniformly dispersed with 0.5 parts of various additives at 295°C, the spinning speed is 1500 m / min, and the draw ratio is 5 times the condition for high-speed melt spinning to obtain graphene / nylon 6 nanocomposites. Nylon 6 fiber. The mechanical properties of graphene / nylon 6 fiber...

Embodiment 2

[0021] Add 0.3 parts by mass of single-layer graphene with a carbon-to-oxygen ratio of 3.0 and a lateral size of 3 μm, 0.1 parts by mass of a molecular weight regulator, and 10 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and heat at 80 ° C at a high speed (400rpm) stirring and mixing to form a dispersion; under the protection of nitrogen, the above dispersion was heated to 250°C in a polycondensation reactor, reacted at 0.7Mpa for 3 hours, and then reacted under vacuum for 4 hours to obtain a polycondensate melt; Then the polymer melt is water-cooled and granulated to obtain the graphene / nylon 6 nanocomposite material. The obtained graphene / nylon 6 nanocomposite material is uniformly dispersed with 0.5 parts of various additives at 295°C, the spinning speed is 2000 m / min, and the draw ratio is 5 times the conditions for high-speed melt spinning to obtain graphene / nylon 6 nanocomposites. Nylon 6 fiber. The mechanical properties of graphene / nylo...

Embodiment 3

[0023] Add 0.2 parts by mass of single-layer graphene with a carbon-to-oxygen ratio of 3.0 and a lateral size of 7 μm, 0.08 parts by mass of a molecular weight regulator, and 10 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and heat at 80 ° C at a high speed (400rpm) stirring and mixing to form a dispersion; under the protection of nitrogen, the above dispersion was heated to 250°C in a polycondensation reactor, reacted at 0.7Mpa for 3 hours, and then reacted under vacuum for 4 hours to obtain a polycondensate melt; Then the polymer melt is water-cooled and granulated to obtain the graphene / nylon 6 nanocomposite material. After the obtained graphene / nylon 6 nanocomposite material and 0.5 parts of various auxiliary agents are uniformly dispersed at 295 ° C, the spinning speed is 2500 m / min, and the draw ratio is 5 times, high-speed melt spinning is carried out to obtain graphene / nylon 6 nanocomposites. Nylon 6 fiber. The mechanical properties of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com