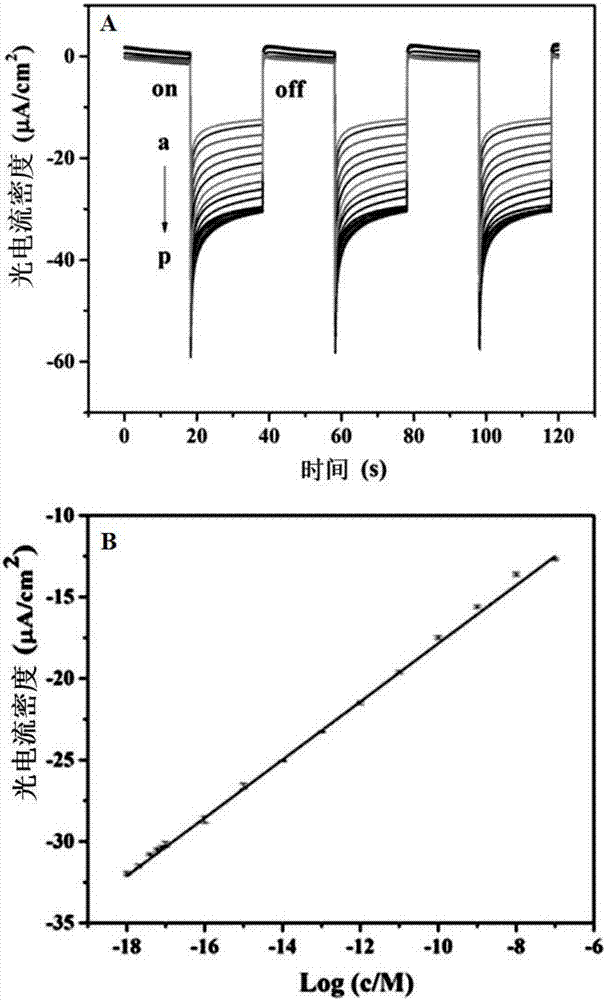

Photoelectrochemical sensor using copper molybdate/barium titanate p-n heterojunction as electrooptic active substance as well as construction method and application of photoelectrochemical sensor

A construction method and photoelectrochemical technology, applied in the field of analysis and detection, can solve the problems of low photoelectric conversion efficiency of photoelectrochemical sensors, not suitable for widespread use, narrow detection range, etc., to achieve quantitative production, easy control of preparation conditions, and selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

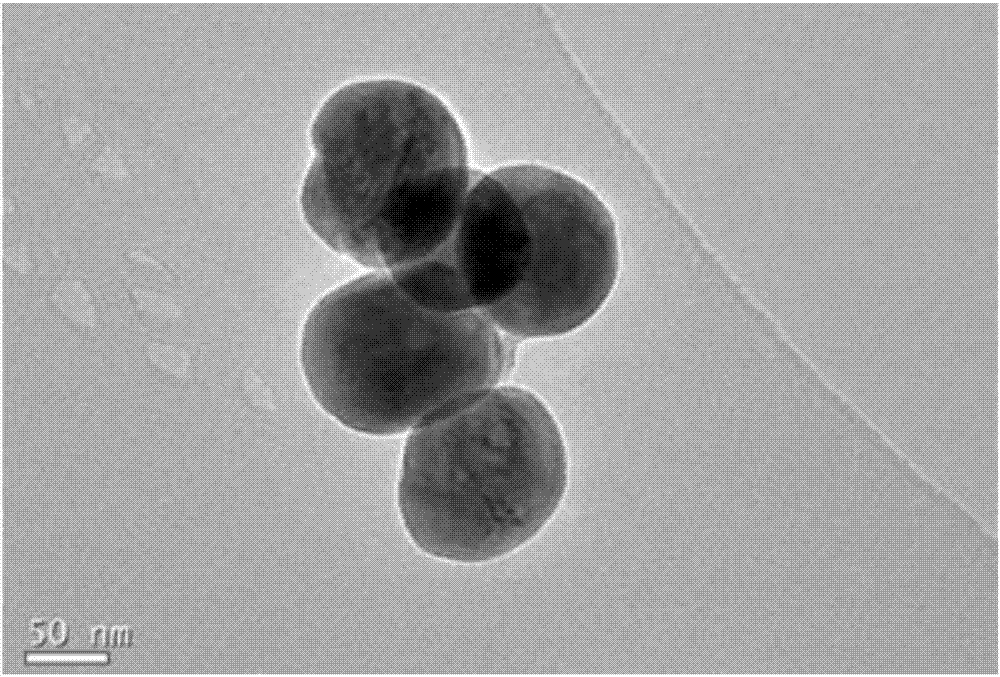

[0035] 2) Preparation of nano-copper molybdate: dissolve polyvinylpyrrolidone and sodium molybdate in water, add copper sulfate solution, mix evenly to obtain a suspension, transfer the suspension to a hydrothermal reaction kettle, and perform a hydrothermal reaction. After the reaction, filter, wash the obtained precipitate with absolute ethanol and water, dry and sinter;

[0036] 3) Preparation of copper molybdate stock solution: dissolve nano-copper molybdate and Nafion in ethanol, and mix well;

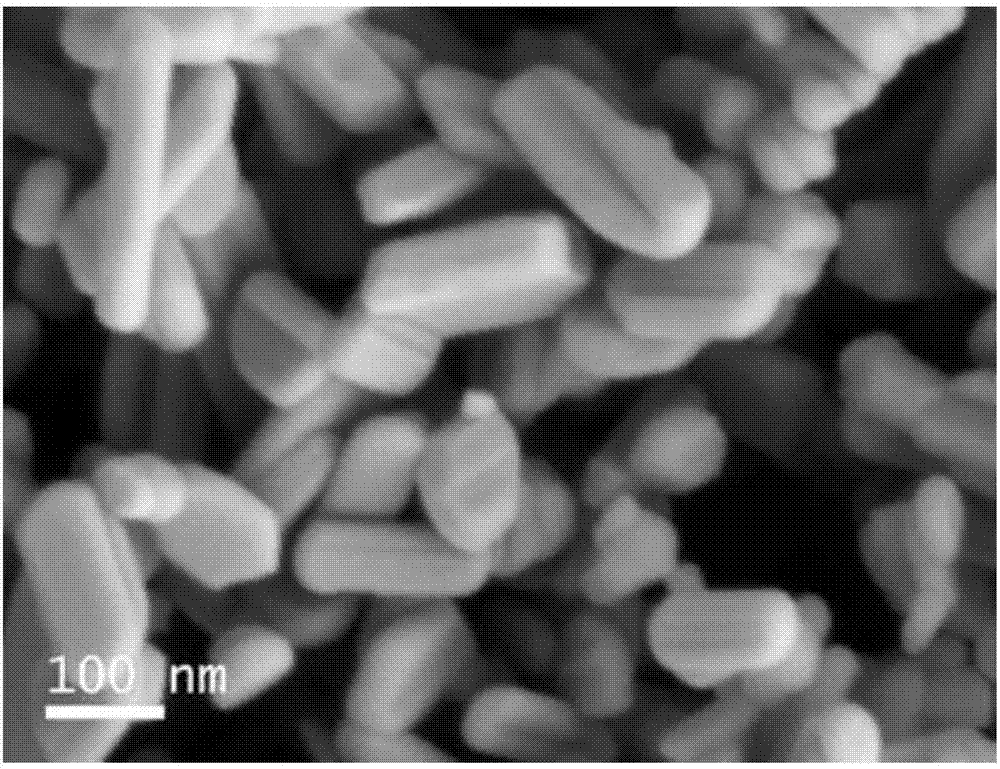

[0037] 4) Preparation of barium titanate stock solution: dissolving nano barium titanate in ethanol and mixing evenly;

[0038] 5) Preparation of photoelectrochemical sensor: Coating the copper molybdate stock solution on the conductive glass sheet, drying, then immersing the conductive glass sheet in the barium titanate stock solution, pulling out the conductive glass sheet, drying, and obtaining the modified molybdic acid Electrode of copper / barium titanate p-n heterojunction, ...

Embodiment 1

[0054] 1) Pretreatment of FTO electrodes: Cut FTO conductive glass to a size of 0.8cm×1.5cm, use acetone, ethanol and ultrapure water to clean ultrasonically for 30 minutes, and dry naturally;

[0055] 2) Preparation of nano-copper molybdate: Dissolve 0.16g polyvinylpyrrolidone (K29-32) and 3mmol sodium molybdate in 30mL ultrapure water, stir at room temperature for 30min, add 30mL molar concentration of 0.1mol / L copper sulfate solution, and stir at room temperature After 30 minutes, the suspension was obtained, and the suspension was transferred to a 100mL hydrothermal reaction kettle, and reacted at 110°C for 12h. After the reaction, filtered, washed with absolute ethanol and water for several times, dried in vacuum at 60°C for 12h, 500 Sintering at ℃ for 3h;

[0056] 3) Preparation of copper molybdate stock solution: dissolve 15 mg of nano-copper molybdate and 5 μL of Nafion in 1 mL of ethanol, and sonicate for 1 h;

[0057] 4) Preparation of barium titanate stock solution...

Embodiment 2

[0061] 1) Pretreatment of ITO electrodes: cut the ITO conductive glass to a size of 0.8cm×1.5cm, use acetone, ethanol and ultrapure water to clean it ultrasonically for 30 minutes, and dry it naturally;

[0062] 2) Preparation of nano-copper molybdate: Dissolve 0.18g polyvinylpyrrolidone (K29-32) and 4mmol sodium molybdate in 30mL ultrapure water, stir at room temperature for 30min, add 40mL molar concentration of 0.1mol / L copper sulfate solution, and stir at room temperature After 30 minutes, the suspension was obtained, and the suspension was transferred to a 100mL hydrothermal reaction kettle, and reacted at 100°C for 15h. After the reaction was completed, filtered, washed with absolute ethanol and water for several times, and vacuum-dried at 60°C for 12h, 400°C Sintering at ℃ for 5h;

[0063] 3) Preparation of copper molybdate stock solution: dissolve 20 mg nano-copper molybdate and 10 μL Nafion in 2 mL ethanol, and sonicate for 1 h;

[0064] 4) Preparation of barium tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com