Preparation method for lithium metatitanate-coated nickel-cobalt-lithium aluminate positive electrode material

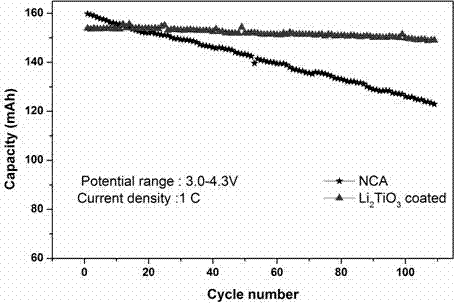

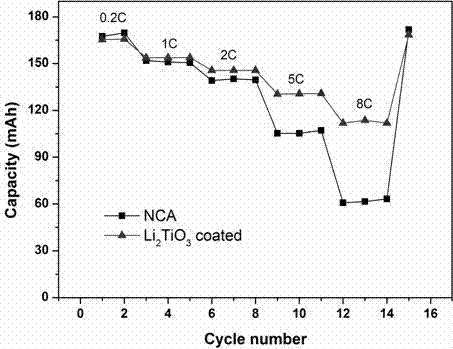

A technology of nickel cobalt lithium aluminate and lithium metatitanate, which is applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of irreversible capacity loss of materials, side reactions of electrolytes, and changes in material structure, so as to reduce the Moisture Sensitivity, Reduced Direct Contact, Improved Safety Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.1g of titanium dioxide into the coating device, and at the same time, add 20g of LiNi 0.8 co 0.15 Al 0.05 o 2 Put it into the coating device, ball mill the mixture for 1 h at room temperature, and pass the sample through a 400-mesh sieve to obtain a solid powder; put the solid powder into a muffle furnace, and heat it up to 600 °C in an air atmosphere at a rate of 5 °C / min. hour, cooled naturally to room temperature, and the prepared sample was passed through a 400-mesh sieve to obtain nickel-cobalt-aluminum lithium coated with lithium metatitanate.

Embodiment 2

[0027] Add 0.1g of titanium dioxide into the coating device, and at the same time, add 20g of LiNi 0.8 co 0.15 Al 0.05 o 2 Put it into the coating device, ball mill the mixture for 1 h at room temperature, and pass the sample through a 400-mesh sieve to obtain a solid powder; put the solid powder into a muffle furnace, heat up to 700 °C at a heating rate of 5 °C / min in an air atmosphere and roast for 3 hour, cooled naturally to room temperature, and the prepared sample was passed through a 400-mesh sieve to obtain nickel-cobalt-aluminum lithium coated with lithium metatitanate.

Embodiment 3

[0029] Add 0.1g of titanium dioxide into the coating device, and at the same time, add 20g of LiNi 0.8 co 0.15 Al 0.05 o 2 Put it into the coating device, ball mill the mixture for 1 h at room temperature, and pass the sample through a 400-mesh sieve to obtain a solid powder; put the solid powder into a muffle furnace, heat up to 300 °C at a heating rate of 5 °C / min in an air atmosphere and roast for 8 hour, cooled naturally to room temperature, and the prepared sample was passed through a 400-mesh sieve to obtain nickel-cobalt-aluminum lithium coated with lithium metatitanate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com