All-fiber 980nm high-power optical fiber oscillator

An all-fiber, high-power technology, applied in lasers, laser components, structure/shape of active medium, etc., can solve the problems of low electro-optical conversion efficiency and limited coupling of pump light, and achieve breakthroughs in pump light power. The effect of limiting and improving electro-optical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

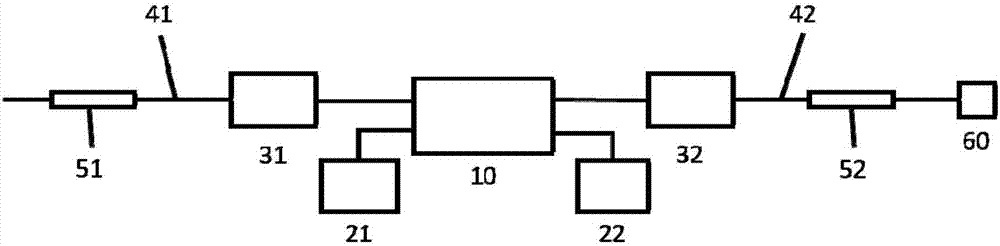

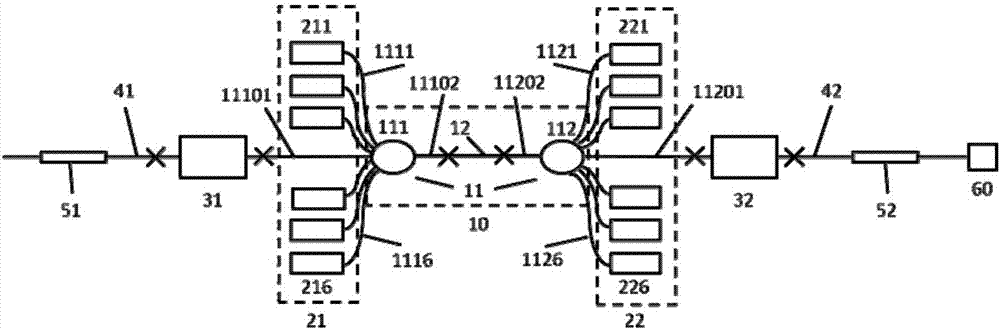

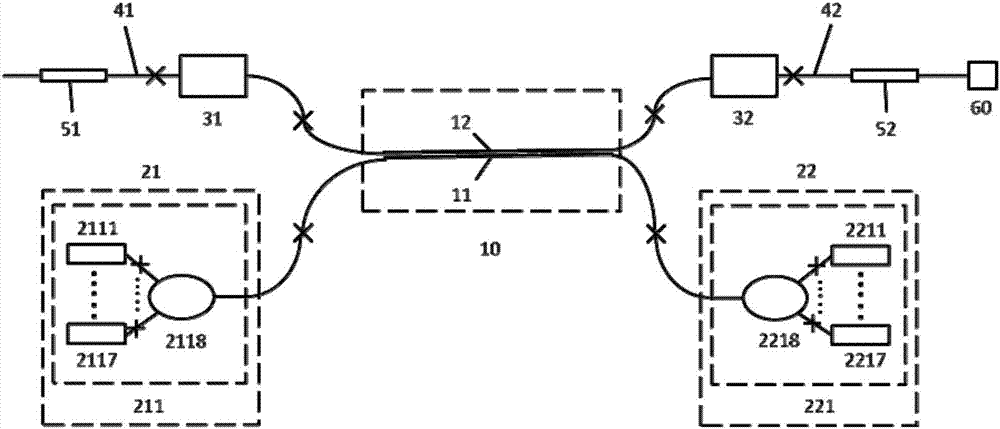

[0034] Such as figure 1 As shown, the present invention consists of a gain module 10, a first pump module 21, a second pump module 22, a first fiber mode field adapter 31, a second fiber mode field adapter 32, a first photosensitive fiber 41, a first fiber grating 51, the second photosensitive optical fiber 42, the second fiber grating 52 and the output coupling end 60. The first pumping module 21 and the second pumping module 22 are respectively connected to the pumping light input end of the gain module 10 . The input ends of the first fiber mode field adapter 31 and the second fiber mode field adapter 32 are respectively connected to the signal light output ports of the gain module 10 . The output end of the first optical fiber mode field adapter 31 is connected with the input end of the first photosensitive optical fiber 41 . The output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com