Large-specification silica loose body production method

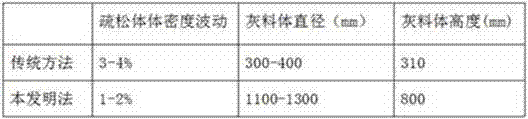

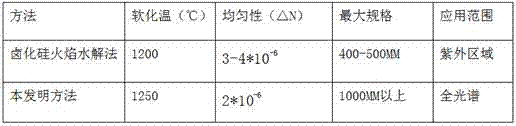

A technology of silica and production method, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of insufficient air permeability of the structure, small diameter of the soot body, poor uniformity of the soot body material, etc., to solve the diameter limitation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, the octamethylcyclotetrasiloxane raw material solution is injected into the raw material tank; and the octamethylcyclotetrasiloxane raw material solution in the raw material tank is passed through N under 0.1MPa pressure condition 2 Transported to the evaporator; at the same time, the temperature of the evaporation tube of the evaporator is stably controlled at 150°C, and the evaporation temperature is controlled at 150°C, so as to vaporize the octamethylcyclotetrasiloxane raw material liquid transported to the evaporator.

[0030] While gasifying the octamethylcyclotetrasiloxane raw material liquid, raise the basic target surface with a diameter greater than 1100 mm, adjust the distance between the burner and the target surface within 250 mm, and control the furnace temperature of the deposition furnace at 200 °C range; when the temperature of the target surface reaches 850 °C, the vaporized octamethylcyclotetrasiloxane raw material liquid is gas-transmitted to t...

Embodiment 2

[0033] First, the dodecamethylcyclohexasiloxane raw material liquid is injected into the raw material tank; and the dodecamethylcyclohexasiloxane raw material liquid in the raw material tank is passed through N under 0.2MPa pressure condition 2 Transported to the evaporator; at the same time, the temperature of the evaporation tube of the evaporator is stably controlled at 180°C, and the evaporation temperature is controlled at 170°C, so that the dodecamethylcyclohexasiloxane raw material liquid transported to the evaporator is vaporized.

[0034] While gasifying the dodecamethylcyclohexasiloxane raw material liquid, raise the basic target surface with a diameter greater than 1100 mm, adjust the distance between the burner and the target surface within 350 mm, and control the furnace temperature of the deposition furnace at the same time 350°C range; when the temperature of the target surface reaches 1000°C, under the condition of 2000g / h, the vaporized dodecamethylcyclohexasil...

Embodiment 3

[0037] First, the hexadecylmethylcyclohexasiloxane raw material solution is injected into the raw material tank; and the hexadecylmethylcyclopentasiloxane raw material solution in the raw material tank is passed through N under the pressure condition of 0.25MPa 2 Transported to the evaporator; at the same time, the temperature of the evaporation tube of the evaporator was stably controlled at 200°C, and the evaporation temperature was controlled at 190°C, so as to vaporize the hexadecylmethylcyclopentasiloxane raw material liquid transported to the evaporator.

[0038] While gasifying the raw material liquid of hexadecylmethylcyclopentasiloxane, raise the basic target surface with a diameter greater than 1100mm, adjust the distance between the burner and the target surface within 400mm, and control the furnace temperature of the deposition furnace at the same time 500°C range; when the temperature of the target surface reaches 1200°C, under the condition of 3000g / h, the vaporiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com