Method for mixed culture of R.salina

A technology of Haematocystis salina and mixed culture, applied in microorganism-based methods, biochemical equipment and methods, unicellular algae, etc. The effect of reducing the cost of pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Halobacter salina (R.salina) seed medium:

[0033] Salina derived seawater, glycerin 10%, Na 2 EDTA·2H 2 O 80mM, H 3 BO 3 2mM, FeCl 3 ·6H 2 O5.02mM, MnSO 4 ·H 2 O 0.01mM, ZnSO 4 ·7H 2 O 0.001mM, CoCl 2 ·6H 2 O 0.001mM, Na 2 EDTA·2H 2 O50mM, HCl 0.1M, HEPES buffer pH 7.8 10mM, Vitamin B 12 0.3g / L.

[0034] The seeds were cultured for two generations, and each generation was carried out in a Erlenmeyer flask with a liquid volume of 50 mL / 250 mL, with an inoculum size of 20% (V / V), and cultured on a shaking table at 23° C. and 120 rpm for 48 hours.

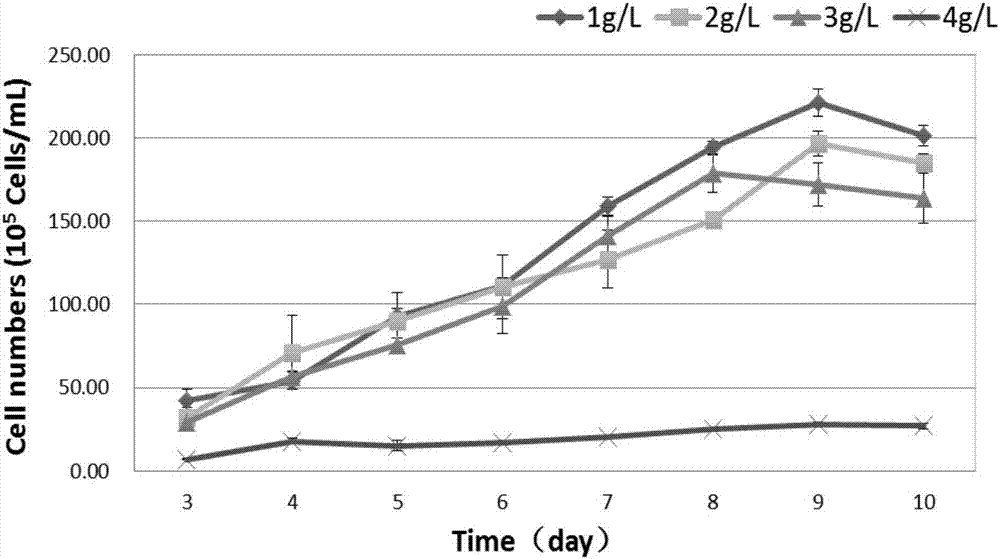

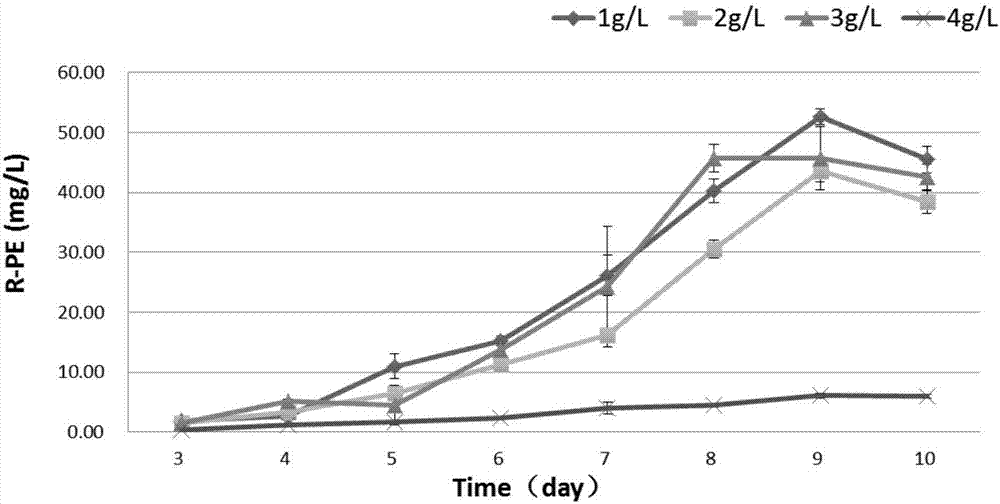

[0035] Then the seed culture medium and the glycerol fermentation medium were respectively according to 10:1, 9:1, 8:1, 7:1, 6:1, 5:1, 4:1, 3:1, 2:1, 1: 1, 1:2, 1:3, 1:4, 1:5, 1:6, 1:7, 1:8, 1:9 and 1:10 were mixed, and Haematobacter salina was mixed with 20% (V / V) of the inoculum was sequentially inserted into the mixed medium with a ratio of 10:1 between the seed medium and the glycerol fermentation medium...

Embodiment 2

[0048] Halobacter salina (R.salina) seed medium:

[0049] Salina derived seawater, glycerin 10%, Na 2 EDTA·2H 2 O 80mM, H 3 BO 3 2mM, FeCl 3 ·6H 2 O5.02mM, MnSO 4 ·H 2 O 0.01mM, ZnSO 4 ·7H 2 O 0.001mM, CoCl 2 ·6H 2 O 0.001mM, Na 2 EDTA·2H 2 O50mM, HCl 0.1M, HEPES buffer pH 7.8 10mM, Vitamin B 12 0.3g / L.

[0050] The seeds were cultured for two generations, and each generation was carried out in a Erlenmeyer flask with a liquid volume of 50 mL / 250 mL, with an inoculum size of 20% (V / V), and cultured on a shaking table at 23° C. and 120 rpm for 48 hours.

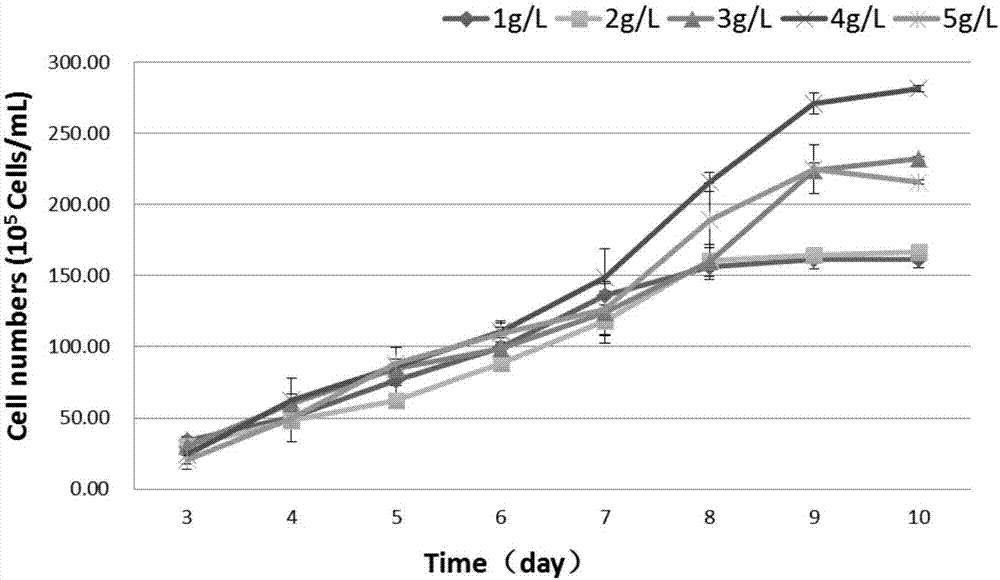

[0051] Then the seed culture medium and the glycerol fermentation medium were respectively according to 10:1, 9:1, 8:1, 7:1, 6:1, 5:1, 4:1, 3:1, 2:1, 1: 1, 1:2, 1:3, 1:4, 1:5, 1:6, 1:7, 1:8, 1:9 and 1:10 were mixed, and Haematobacter salina was mixed with 20% (V / V) of the inoculum was sequentially inserted into the mixed culture medium with a ratio of 10:1 between the seed culture medium and the glycerol fer...

Embodiment 3

[0064] Halobacter salina (R.salina) seed medium:

[0065] Salina derived seawater, glycerin 10%, Na 2 EDTA·2H 2 O 80mM, H 3 BO 3 2mM, FeCl 3 ·6H 2 O5.02mM, MnSO 4 ·H 2 O 0.01mM, ZnSO 4 ·7H 2 O 0.001mM, CoCl 2 ·6H 2 O 0.001mM, Na 2 EDTA·2H 2 O50mM, HCl 0.1M, HEPES buffer pH 7.8 10mM, Vitamin B 12 0.3g / L.

[0066] The seeds were cultured for two generations, and each generation was carried out in a Erlenmeyer flask with a liquid volume of 50 mL / 250 mL, with an inoculum size of 20% (V / V), and cultured on a shaking table at 23° C. and 120 rpm for 48 hours.

[0067] Then the seed culture medium and the glycerol fermentation medium were respectively according to 10:1, 9:1, 8:1, 7:1, 6:1, 5:1, 4:1, 3:1, 2:1, 1: 1, 1:2, 1:3, 1:4, 1:5, 1:6, 1:7, 1:8, 1:9 and 1:10 were mixed, and Haematobacter salina was mixed with 20% (V / V) of the inoculum was sequentially inserted into the mixed medium with a ratio of 10:1 of the seed medium and the glycerol fermentation medium, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com