Fluorescent acrylic fiber and preparation method of same

A technology of acrylic fiber and preparation process, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of poor fluorescence fastness, unsatisfactory fluorescence effect, low utilization rate of fluorescent powder, etc., and achieve high effective utilization rate , Good fluorescence fastness, good fluorescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, a fluorescent acrylic fiber is composed of a core layer and a skin layer, the core layer is polyacrylonitrile, and the skin layer is a mixture of fluorescent powder and polyacrylonitrile. Among them, the number average molecular weight of polyacrylonitrile is about 35000, and the fluorescent powder is the powder obtained by milling barium magnesium aluminate activated by europium to 20000 mesh by mechanical ball mill.

[0029] The preparation steps of the fluorescent acrylic fiber of the present embodiment are as follows:

[0030] 1) Preparation of acrylic fiber spinning stock solution: dissolving polyacrylonitrile prepared by solution polymerization in dimethylformamide and degassing and filtering to obtain acrylic fiber spinning stock solution 1; polyacrylonitrile in acrylic fiber spinning stock solution The weight ratio concentration is 28%;

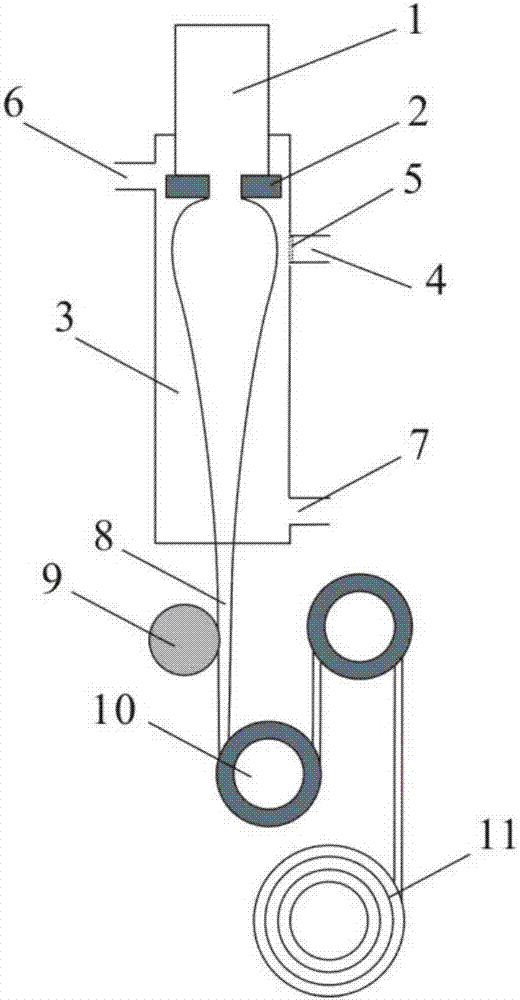

[0031] 2) Spinning: After the acrylic fiber spinning stock solution 1 output by the metering pump is spr...

Embodiment 2

[0035] In this embodiment, a fluorescent acrylic fiber is composed of a core layer and a skin layer, the core layer is polyacrylonitrile, and the skin layer is a mixture of fluorescent powder and polyacrylonitrile. Among them, the number-average molecular weight of polyacrylonitrile is about 45000, and the fluorescent powder is the powder obtained by milling europium-activated yttrium oxide to 25000 mesh with a mechanical ball mill.

[0036] The preparation steps of the fluorescent acrylic fiber of the present embodiment are as follows:

[0037] 1) Preparation of acrylic fiber spinning stock solution: dissolving polyacrylonitrile prepared by solution polymerization in dimethylformamide and degassing and filtering to obtain acrylic fiber spinning stock solution 1; polyacrylonitrile in acrylic fiber spinning stock solution The weight ratio concentration is 33%;

[0038] 2) Spinning: After the acrylic fiber spinning stock solution 1 output by the metering pump is sprayed out from ...

Embodiment 3

[0042] In this embodiment, a fluorescent acrylic fiber is composed of a core layer and a skin layer, the core layer is polyacrylonitrile, and the skin layer is a mixture of fluorescent powder and polyacrylonitrile. Among them, the number-average molecular weight of polyacrylonitrile is about 40,000, and the fluorescent powder is a powder obtained by ball milling terbium-activated aluminate to 23,000 mesh with a mechanical ball mill.

[0043] The preparation steps of the fluorescent acrylic fiber of the present embodiment are as follows:

[0044] 1) Preparation of acrylic fiber spinning stock solution: dissolving polyacrylonitrile prepared by solution polymerization in dimethylformamide and degassing and filtering to obtain acrylic fiber spinning stock solution 1; polyacrylonitrile in acrylic fiber spinning stock solution The weight ratio concentration is 30%;

[0045] 2) Spinning: After the acrylic fiber spinning stock solution 1 output by the metering pump is sprayed out thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com