Aperture-controllable CS/PLA oil-water separating nanometer fiber film and preparation method thereof

A nanofiber membrane, oil-water separation technology, applied in fiber processing, filament/thread forming, textile and paper making, etc., can solve the problems of pollution, high cost, unfavorable control, etc., achieve simple process, low cost, improve oil flow volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] At room temperature, 0.2g CS was dissolved in 10g 90% acetic acid solution to obtain CS solution; at 30°C, 0.1g PLA was dissolved in 10mL chloroform to obtain PLA solution. At room temperature, add 3g of CS solution to 9g of PLA solution, add 4g of absolute ethanol dropwise, and stir for 4 hours to obtain a uniform sol-spinning solution; inject the sol-spinning solution into the electrospinning equipment, at 25°C, voltage 20kV , the ejection rate of the sol-spinning liquid is 2mL / h, and the distance between the spinning receiving plate and the electrode is 15cm, and the receiving plate used is a stainless steel plate (0 mesh). After drying for 24 hours, a CS / PLA nanofibrous membrane for oil-water separation with controllable pores was obtained.

Embodiment 2

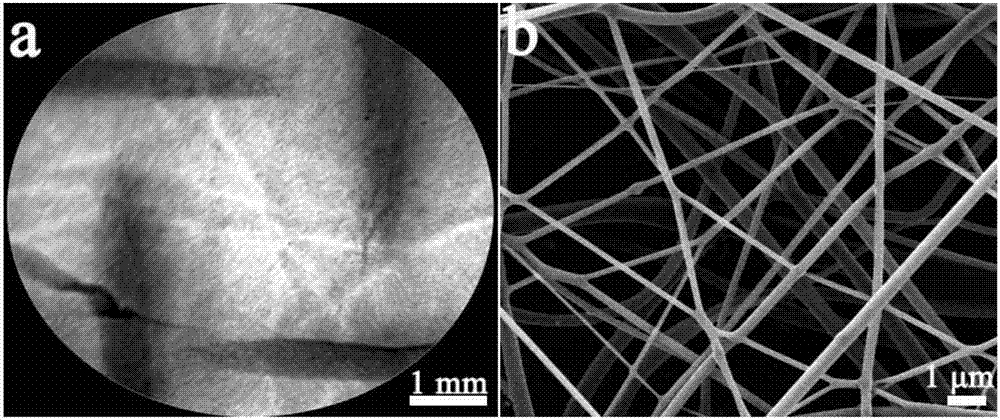

[0047] At room temperature, 0.2g CS was dissolved in 10g 90% acetic acid solution to obtain CS solution; at 30°C, 0.1g PLA was dissolved in 10mL chloroform to obtain PLA solution. At room temperature, add 3g of CS solution to 9g of PLA solution, add 4g of absolute ethanol dropwise, and stir for 4 hours to obtain a uniform sol-spinning solution; inject the sol-spinning solution into the electrospinning equipment, at 25°C, voltage 20kV , the ejection speed of the sol spinning liquid is 2mL / h, and the distance between the spinning receiving plate and the electrode is 15cm, and the receiving plate used is a 40-mesh stainless steel mesh. A CS / PLA nanofibrous membrane for oil-water separation with controllable pores was obtained.

Embodiment 3

[0049] At room temperature, 0.2g CS was dissolved in 10g 90% acetic acid solution to obtain CS solution; at 30°C, 0.1g PLA was dissolved in 10mL chloroform to obtain PLA solution. At room temperature, add 3g of CS solution to 9g of PLA solution, add 4g of absolute ethanol dropwise, and stir for 4 hours to obtain a uniform sol-spinning solution; inject the sol-spinning solution into the electrospinning equipment, at 25°C, voltage 20kV , the spraying speed of the sol spinning liquid is 2mL / h, and the distance between the spinning receiving plate and the electrode is 15cm, and the receiving plate used is a 30-mesh stainless steel mesh. A CS / PLA nanofibrous membrane for oil-water separation with controllable pores was obtained.

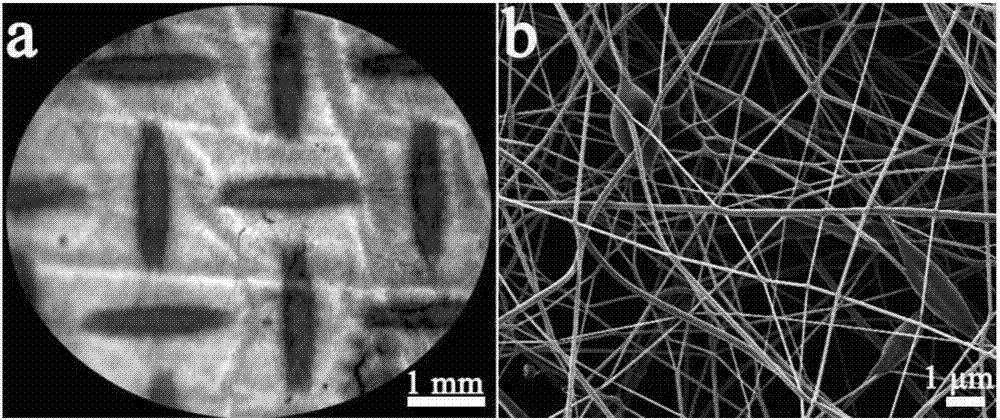

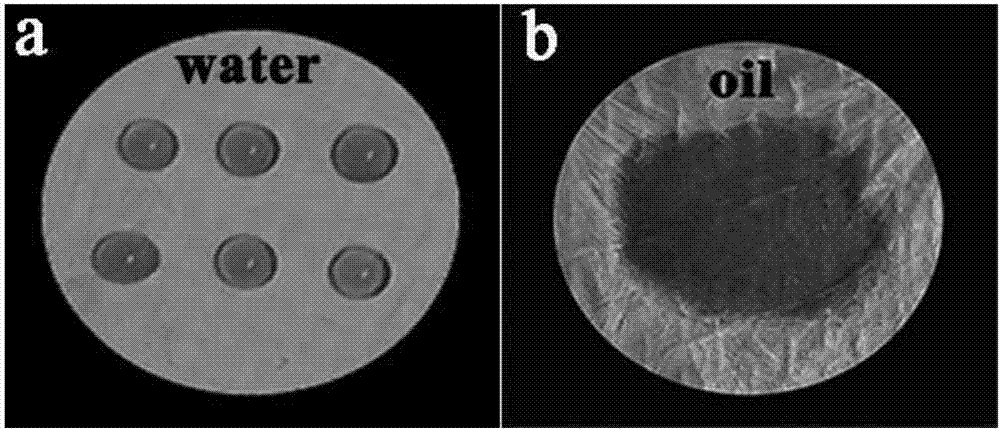

[0050] figure 1 Optical micrograph a and scanning photo b of the CS / PLA oil-water separation nanofiber membrane prepared for this example. Depend on figure 1 It can be seen that the average diameter of the CS / PLA oil-water separation nanofibers prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com