Negative electrode pole piece of low-temperature type lithium ion battery for mobile base station, preparation method and lithium ion battery

A technology for lithium ion batteries and mobile base stations, applied in the field of lithium ion batteries, can solve the problems of poor low temperature performance of negative electrode sheets, and achieve the effects of good low temperature charge and discharge performance, meeting requirements for use, and improving low temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

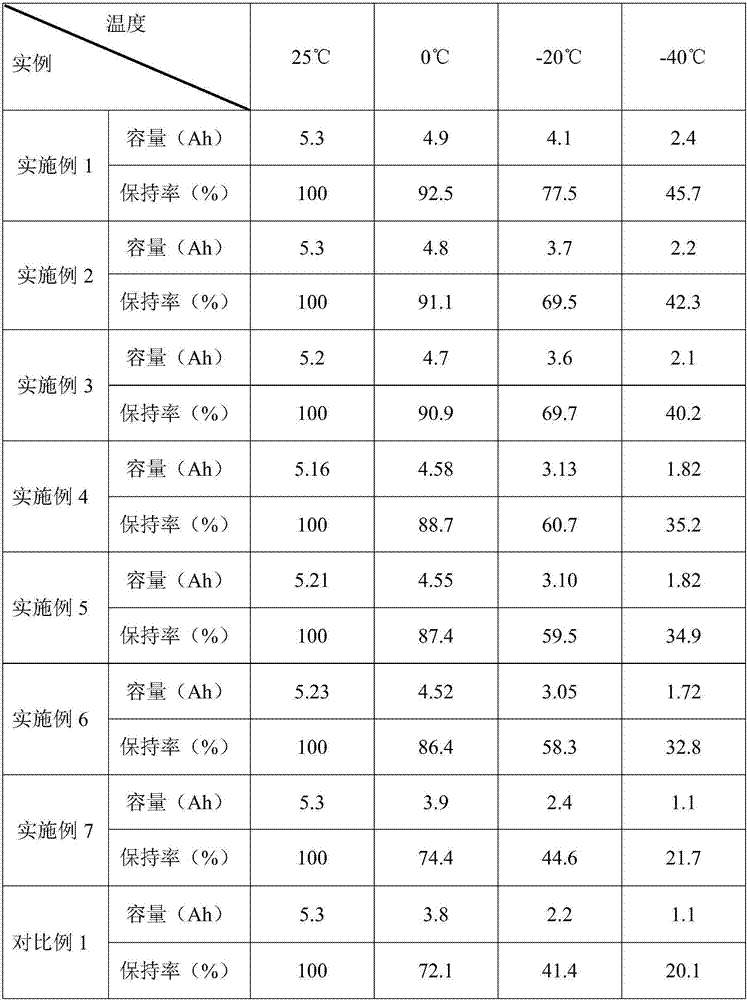

Embodiment 1

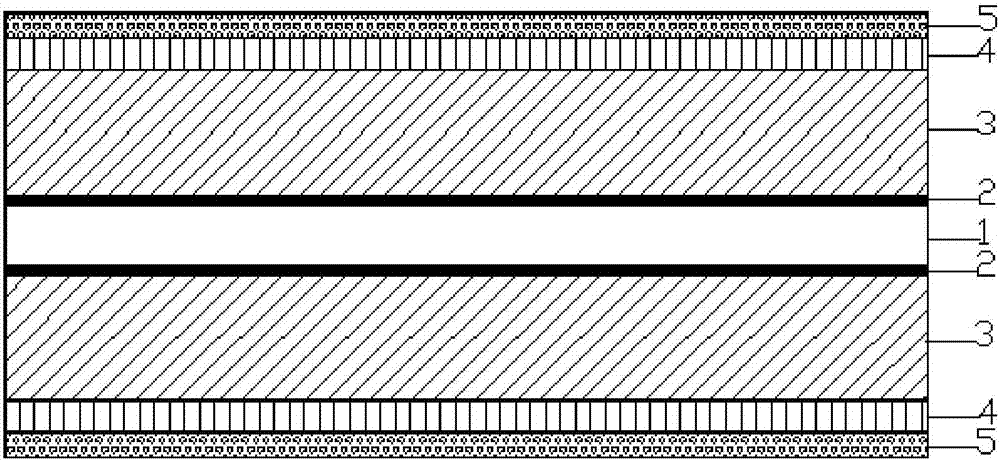

[0034] The low-temperature lithium-ion battery negative electrode sheet for mobile base stations of this embodiment has a schematic structural diagram as figure 1 As shown, it includes a current collector (copper foil) 1 and a conductive layer 2, an active material layer 3, a solid electrolyte layer 4, and an energy storage functional layer 5 that are sequentially arranged on both sides of the current collector 1 along the direction away from the thickness of the current collector; the conductive layer consists of Composed of three-dimensional carbon material and polyvinylidene fluoride, the mass ratio of three-dimensional carbon material and polyvinylidene fluoride is 70:30; the active material layer is composed of graphite, SP conductive agent and polyvinylidene fluoride, and the mass ratio of the three is 94: 1:5; the solid electrolyte layer is composed of solid electrolyte Li 5 La 3 Ta 2 o 12 , carbon nanotubes, polyvinylidene fluoride, the mass ratio of the three is 3:...

Embodiment 2

[0043] The low-temperature lithium-ion battery negative electrode sheet for mobile base stations in this embodiment has the same structure as in Embodiment 1, wherein the conductive layer is composed of a three-dimensional carbon material and polyvinylidene fluoride, and the mass ratio of the three-dimensional carbon material and polyvinylidene fluoride is 80:20; the active material layer is composed of graphite, SP conductive agent and polyvinylidene fluoride, and the mass ratio of the three is 94:1:5; the solid electrolyte layer is composed of solid electrolyte Li 5 La 3 Nb 2 o 12 , graphene, polyvinylidene fluoride, the mass ratio of the three is 1:1:10; the energy storage functional layer is composed of pentaerythritol phosphate melamine salt, graphene, polyvinylidene fluoride, and the mass ratio of the three is 1: 1:10.

[0044] The preparation method of the low-temperature lithium-ion battery negative electrode sheet for mobile base stations of the present embodiment ...

Embodiment 3

[0052] The low-temperature lithium-ion battery negative electrode sheet for mobile base stations in this embodiment has the same structure as in Embodiment 1, wherein the conductive layer is composed of a three-dimensional carbon material and polyvinylidene fluoride, and the mass ratio of the three-dimensional carbon material and polyvinylidene fluoride is 60:40; the active material layer is composed of graphite, SP conductive agent and polyvinylidene fluoride, and the mass ratio of the three is 94:1:5; the solid electrolyte layer is composed of solid electrolyte Li 6 BaLa 2 Ta 2 o 12 , gas phase growth carbon fiber, polyvinylidene fluoride, the mass ratio of the three is 5:5:20; the energy storage functional layer is composed of ammonium polyphosphate, vapor phase growth carbon fiber, polyvinylidene fluoride, the mass ratio of the three is 5 :5:20.

[0053] The preparation method of the low-temperature lithium-ion battery negative electrode sheet for mobile base stations o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com